Dicing die-bonding film

A chip bonding film and cutting film technology, which is applied in the fields of film/sheet adhesive, thin material processing, semiconductor/solid device manufacturing, etc., can solve problems such as difficult to achieve uniform adhesive layer, and achieve excellent moisture resistance and reliability , The effect of preventing reflow soldering cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The acrylic polymer can be produced by applying a suitable method such as solution polymerization, emulsion polymerization, bulk polymerization or suspension polymerization to one component monomer or a mixture of two or more component monomers. From the viewpoint of preventing wafer contamination, etc., the adhesive layer preferably has a composition that suppresses the inclusion of low-molecular-weight substances. From this point of view, an acrylic polymer having a weight average molecular weight of 300,000 or more, especially 400,000 to 3 million is preferable. As the main component, the binder may be of an appropriate crosslinking type such as internal crosslinking or external crosslinking.

[0072] In addition, in order to control the crosslinking density of the adhesive layer 2, for example, polyfunctional isocyanate compounds, polyfunctional epoxy compounds, melamine compounds, metal salt compounds, metal chelating agent compounds, amino resin compounds, etc. Co...

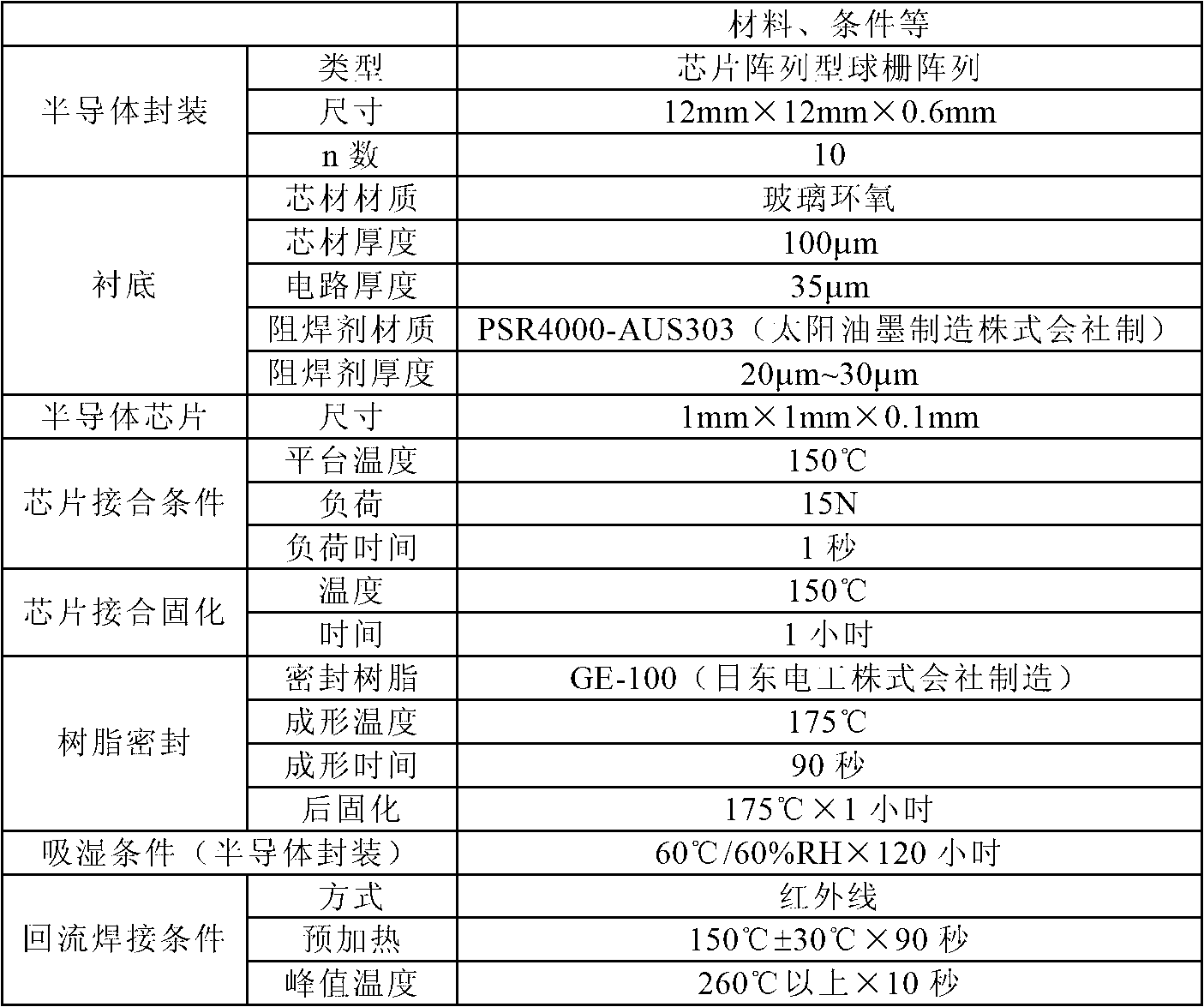

Embodiment 1

[0137] Preferred embodiments of the present invention are illustrated in detail below. In addition, the present invention is not limited to these Examples.

Embodiment 1)

[0139] [Manufacturing of Die Bonding Film]

[0140] 100 parts by weight of an acrylate polymer mainly composed of ethyl acrylate-methyl methacrylate (manufactured by Negami Industry Co., Ltd., Paraclon W-197CM), 3 parts by weight of a polyfunctional isocyanate crosslinking agent, 23 parts by weight Epoxy resin (Epicoat 1004, manufactured by Japan Epoxy Resin Co., Ltd.) and 6 parts by weight of phenolic resin (Milex XLC-CC, manufactured by Mitsui Chemicals Co., Ltd.) were dissolved in methyl ethyl ketone to prepare an adhesive composition with a concentration of 20% by weight. solution.

[0141] Then, the solution of the adhesive composition was applied to a release-treated film composed of a polyethylene terephthalate film (thickness 50 μm) after a silicone release treatment as a release liner. . It was then dried at 120° C. for 3 minutes. Thus, a die-bonding film A having a thickness of 25 μm was produced on the release-treated film.

[0142] [Manufacturing of cutting fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com