Preparation method for fiber-based activate core-shell micro-nano structure environment purifying material

A technology of micro-nano structure and environmental purification, applied in fiber treatment, light water/sewage treatment, textile and papermaking, etc., to achieve the effect of wide source, easy industrial production and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Wool fabric surface pretreatment

[0043]Ultrasonic cleaning of wool fabric (1g) with acetone for 30min, drying at 20°C for 10h, then treating in high-efficiency detergent Kieralon OL (Basf) solution at 40°C for 15min, drying at 80°C for 30min;

[0044] (2) Preparation of solution A

[0045] Under nitrogen atmosphere, take 0.005mol bismuth nitrate and 0.010mol edetate disodium into 50ml nitric acid solution (0.5mol / L) respectively, and drop Tween 80, a wetting agent 2% relative to the weight of the fabric, at 200rpm Stir for 30min, add 4gNaHCO 3 ;

[0046] Preparation of Solution B

[0047] Under a nitrogen atmosphere, take 0.005mol of sodium metavanadate and add it to 50ml of deionized water, stir at 200rpm for 5min, and add 10ml of sodium hydroxide solution (1.5mol / L) dropwise during the stirring process to obtain a clear solution;

[0048] (3) Preparation of unactivated photocatalyst

[0049] Add the above solution B to the above solution A dropwise, control...

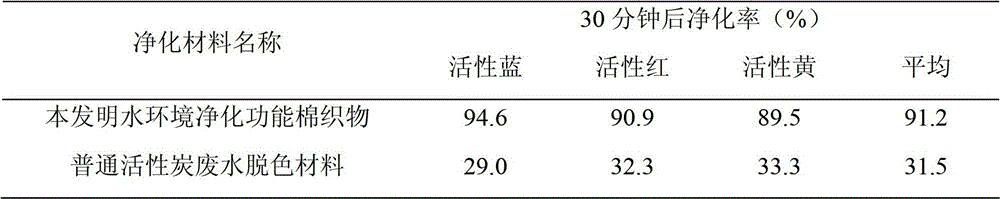

Embodiment 2

[0059] (1) Cotton fabric surface pretreatment

[0060] Ultrasonic cleaning of cotton fabric (1g) with ethanol for 45min, drying at 30°C for 10h, then treating in the high-efficiency cleaning agent Span-one (Desang Chemical) solution at 45°C for 20min, drying at 80°C for 25min;

[0061] (2) Preparation of solution A

[0062] Under a nitrogen atmosphere, take 0.006mol of bismuth nitrate and 0.015mol of disodium edetate and add them to 50ml of nitric acid solution (1.0mol / L) respectively, and add 3% of the wetting agent Triton X-100 relative to the weight of the fabric dropwise, Stir at 200rpm for 30min, add 3g K 2 CO 3 ;

[0063] Preparation of Solution B

[0064] Under a nitrogen atmosphere, take 0.006mol of sodium metavanadate and add it to 50ml of deionized water, stir at 200rpm for 5min, and add 10ml of sodium hydroxide solution (0.5mol / L) dropwise during the stirring process to obtain a clear solution;

[0065] (3) Preparation of unactivated photocatalyst

[0066] Add...

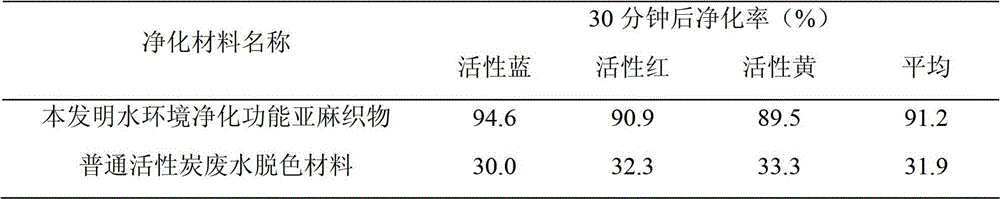

Embodiment 3

[0076] (1) Surface pretreatment of linen fabric

[0077] Ultrasonic cleaning of linen fabric (1g) with acetone for 60min, drying at 30°C for 10h, then treating in high-efficiency detergent LS (Demei Chemical) solution at 45°C for 20min, drying at 80°C for 25min;

[0078] (2) Preparation of solution A

[0079] Under nitrogen atmosphere, take 0.006mol bismuth nitrate and 0.018mol edetate disodium into 50ml nitric acid solution (2.0mol / L) respectively, and add 5% wetting agent JFC (fatty alcohol poly Oxyethylene ether), stirred at 200rpm for 30min, added 4g Na 2 CO 3 ;

[0080] Preparation of Solution B

[0081] Under a nitrogen atmosphere, take 0.006mol of sodium metavanadate and add it to 50ml of deionized water, stir at 200rpm for 5min, and add 10ml of sodium hydroxide solution (1mol / L) dropwise during the stirring process to obtain a clear solution;

[0082] (3) Preparation of unactivated photocatalyst

[0083] Add the above solution B to the above solution A dropwise, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com