Fabricating method of concrete preformed pile in saline soil region

A technology of concrete prefabricated piles and manufacturing methods, applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of application limitations, poor corrosion resistance, etc., and achieve the effects of reduced emissions, good durability, and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concrete prefabricated pipe pile is made by adopting the method for making the concrete prefabricated pile of the present invention, the pile is 6m long, the outer diameter is 50cm, and the wall thickness is 10cm. The cementitious material concrete is prepared according to the raw materials in parts by weight of the following components:

[0038] Lightly burned magnesia powder: 150 parts;

[0039] Red mud tailings powder is selected as mineral admixture: 50 parts;

[0040] Coarse aggregate: 200 parts;

[0041] Fine aggregate: 200 parts;

[0042] Water: 120 parts.

[0043] Its production process is as follows:

[0044] (1) Mixing and stirring of raw materials: Mix and stir the various raw materials measured separately according to the ratio.

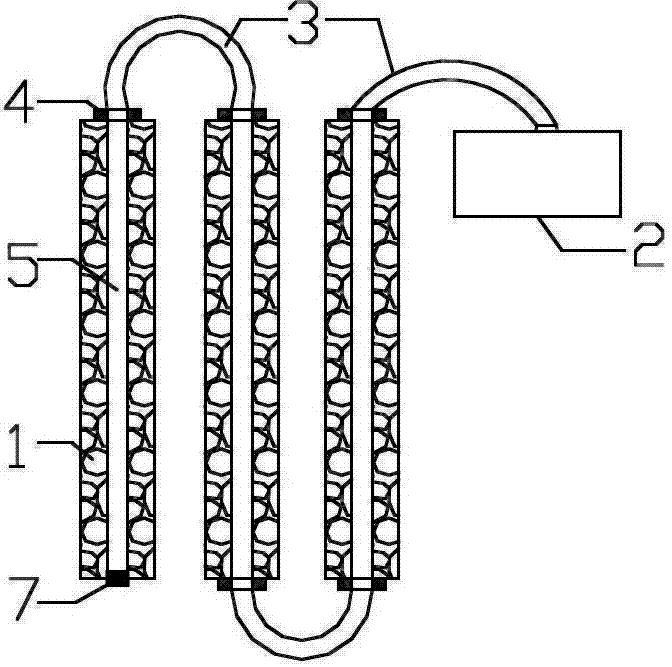

[0045] (2) Mixture molding: Put the carbon fiber reinforced plastic rib skeleton into the steel mold that has been assembled, and bind it in the mold, and then use the centrifugal molding method to carry out the mixture mo...

Embodiment 2

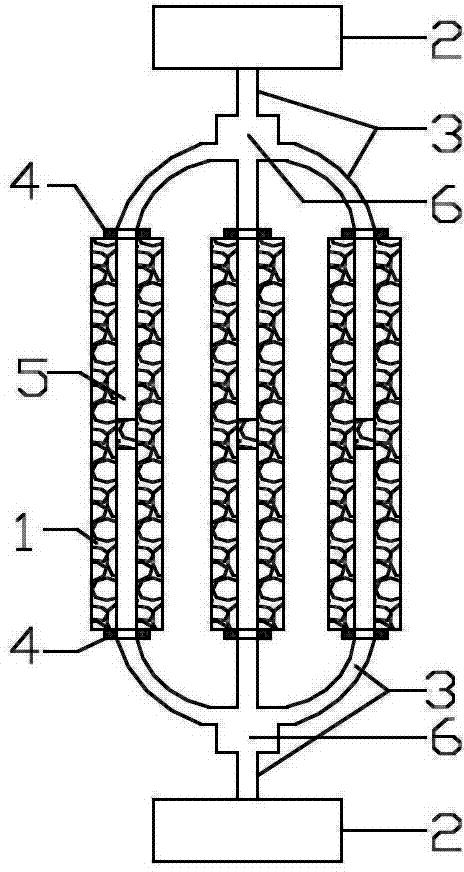

[0049] The concrete prefabricated pile is manufactured by the method for manufacturing the concrete prefabricated pile of the present invention. The length of the pile is 8m, and the section is 50cm×50cm. On the cross section of the pile, 4 through holes with a diameter of 15cm are arranged along the direction of the pile body, arranged in a square. The shortest distance between sides is 14.5cm. The cementitious material concrete is prepared according to the raw materials in parts by weight of the following components:

[0050] Lightly burned magnesia powder: 350 parts;

[0051] Quicklime: 300 parts;

[0052] The mineral admixture is selected from granulated blast furnace slag: 550 parts;

[0053] Coarse aggregate: 1500 parts;

[0054] Fine aggregate: 900 parts;

[0055] Water: 400 parts.

[0056] Its production process is as follows:

[0057] (1) Mixing and stirring of raw materials: Mix and stir the various raw materials measured separately according to the ratio.

...

Embodiment 3

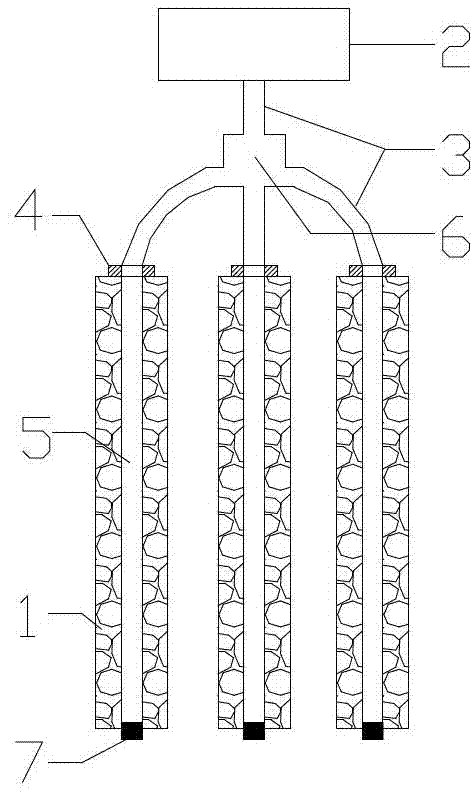

[0062] Adopt concrete prefabricated pile manufacturing method of the present invention to make reinforced concrete prefabricated pile, pile is long 10m, and pile section adopts such as figure 2 The cross-section shown. The cementitious material concrete is prepared according to the raw materials in parts by weight of the following components:

[0063] Lightly burned magnesia powder: 200 parts;

[0064] Quicklime: 100 parts;

[0065] Silica fume is selected as mineral admixture: 100 parts, steel slag: 50 parts;

[0066] Coarse aggregate: 1000 parts;

[0067] Fine aggregate: 100 parts;

[0068] Fiberglass: 1 part;

[0069] Water: 190 parts.

[0070] Its production process is as follows:

[0071] (1) Mixing and stirring of raw materials: Mix and stir the various raw materials measured separately according to the ratio.

[0072] (2) Mixture molding: Put the bamboo reinforcement skeleton into the steel mold that has been assembled, and then pour in the evenly stirred concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com