Composite corrosion and scale inhibitor for reclaimed water as circulating cooling water of power plant

A technology of circulating cooling water, corrosion and scale inhibitor, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc. The requirements of concentration rate operation, the difficulty of corrosion and scale inhibitor to achieve the effect of corrosion and scale inhibition, etc., to achieve the effect of less dosage, scientific and reasonable ratio and process, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

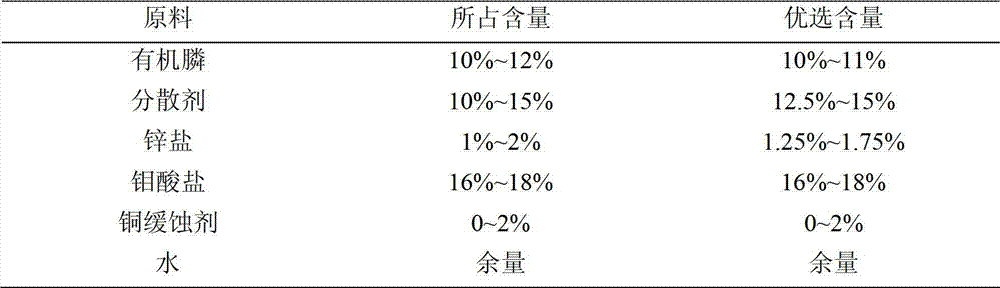

[0022] Composition (mass percentage) and theoretical phosphorus content of composite corrosion and scale inhibitors:

[0023] Organic phosphine (2-phosphonic acid butane-1,2,4-tricarboxylic acid) 10%, dispersant (acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer) 10%, zinc salt (sulfuric acid Zinc) 1%, molybdate (sodium molybdate) 16%, water 63%; theoretical phosphorus content (calculated as P, mass fraction): 1.15%.

[0024] experimental method:

[0025] The corrosion inhibition performance was measured with reference to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotating Coupon Method", and the coupon materials used in the experiment were Q235 carbon steel and 316L stainless steel. Hang three pieces of each material, and the results are averaged.

[0026] Determination of scale inhibition performance refers to "GB / T 16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Perfor...

Embodiment 2

[0031] Composition (mass percentage) and theoretical phosphorus content of composite corrosion and scale inhibitors:

[0032] Organic phosphine (2-phosphonic acid butane-1,2,4-tricarboxylic acid) 10%, organic phosphine (hydroxyethylidene diphosphonic acid) 2%, dispersant (acrylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer) 15%, zinc salt (zinc sulfate) 2%, molybdate (sodium molybdate) 18%, copper corrosion inhibitor (benzotriazole) 2%, water 51%; theoretical phosphorus Amount (in terms of P, mass fraction): 1.75%.

[0033] experimental method:

[0034] Corrosion inhibition performance was measured with reference to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotating Coupon Method", and the materials for the test coupons were Q235 carbon steel, H62 brass and 316L stainless steel. Hang three pieces of each material, and the results are averaged.

[0035] Determination of scale inhibition performance refers to...

Embodiment 3

[0040] Composition (mass percentage) and theoretical phosphorus content of composite corrosion and scale inhibitors:

[0041] Organic phosphine (2-phosphonic acid butane-1,2,4-tricarboxylic acid) 10%, dispersant (acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer) 12.5%, zinc salt (sulfuric acid Zinc) 1%, molybdate (sodium molybdate) 16%, water 60.5%; theoretical phosphorus content (calculated as P, mass fraction): 1.15%.

[0042] experimental method:

[0043] The corrosion inhibition performance was measured with reference to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotating Coupon Method", and the coupon materials used in the experiment were Q235 carbon steel and 316L stainless steel. Hang three pieces of each material, and the results are averaged.

[0044] Determination of scale inhibition performance refers to "GB / T 16632-2008 Calcium Carbonate Deposition Method for Determination of Scale Inhibition Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total alkalinity | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com