Method for preparing zirconium carbide ceramic powder

A technology of ceramic powder and zirconium carbide, which is applied in the field of preparation of zirconium carbide ceramic powder, can solve the problems of high cost, high energy consumption, long synthesis time, etc. the effect of growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Dissolve 8g of sucrose in 50mL of solvent acetic acid at a temperature of 85°C, and cool the resulting solution to room temperature to obtain a carbon source solution (used as a carbon source); mix 8mL of zirconium n-propoxide with 24mL of diluent n-propanol After dilution, place it in a constant temperature water bath at 25°C and stir for 20 minutes, add 3 mL of chelating agent acetic acid to the mixture, and stir for 15 minutes to make it evenly mixed to obtain a zirconium n-propoxide mixture; press zirconium n-propoxide The substance mass ratio with sucrose is 12:4.4. Measure the carbon source solution, and dilute it with 40mL of n-propanol to obtain a carbon source mixed solution; Stir at 25°C for 2 days and mix well. After aging for 1 day, a dark red gel was obtained, then dried in a drying oven at 150°C for 48 hours, and dry-milled for 1 hour to obtain xerogel powder.

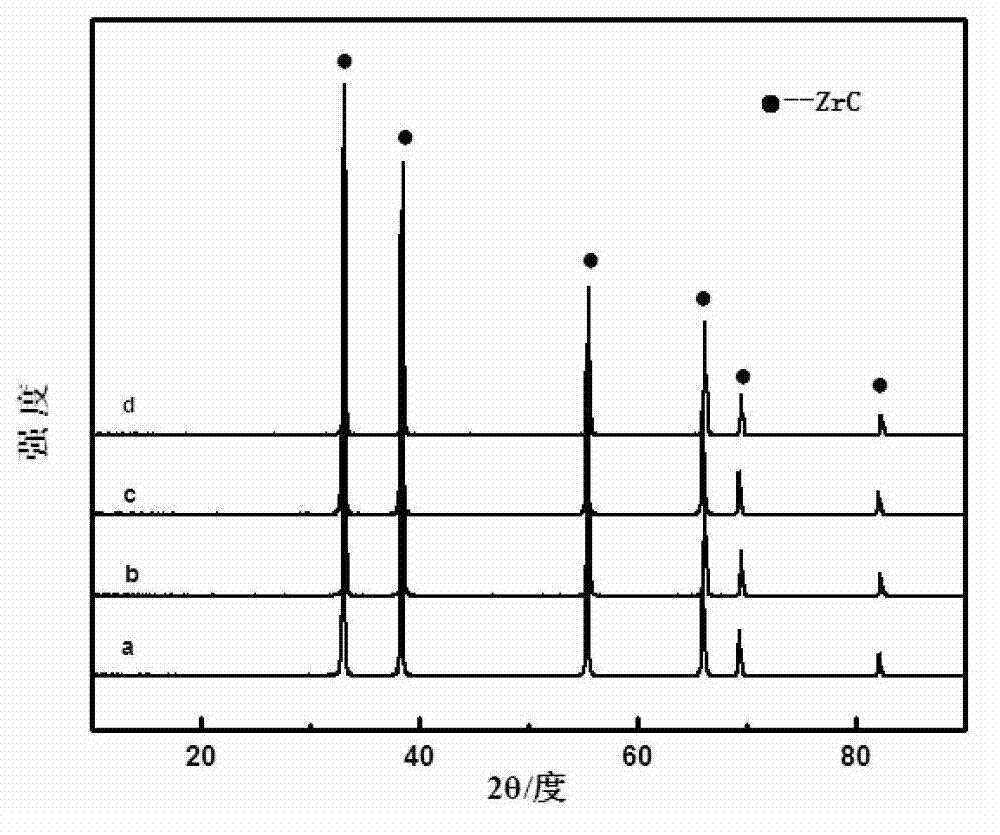

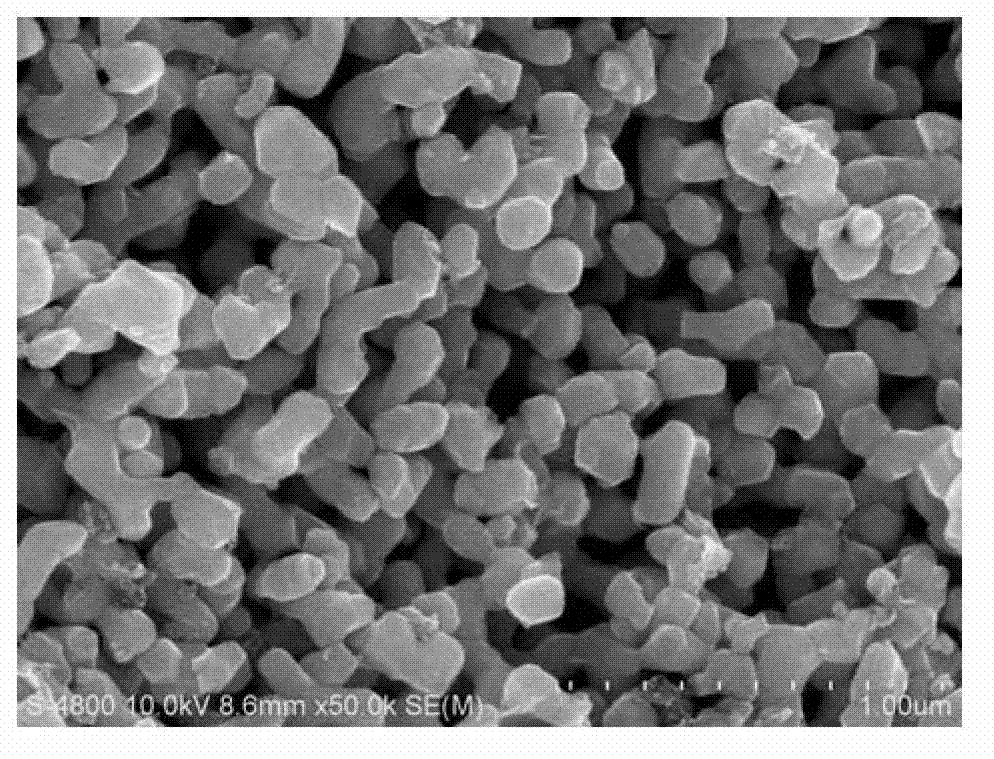

[0034] (2) The dry gel powder was heat-treated in a tube furnace under the protection of arg...

Embodiment 2

[0038] (1) Dissolve 7.5g of sucrose in 50mL of solvent acetic acid at a temperature of 75°C, and cool the resulting solution to room temperature to obtain a carbon source solution (used as a carbon source); mix 8mL of zirconium n-propoxide with 16mL of diluent n-propyl After diluting with alcohol, place it in a constant temperature water bath at 30°C and stir for 20 minutes, add 2 mL of chelating agent acetic acid to the mixture, and stir for 15 minutes to make it evenly mixed to obtain a zirconium n-propoxide mixture. Measure the carbon source solution according to the mass ratio of zirconium n-propoxide and sucrose as 12:4, and dilute it with 16mL of n-propanol to obtain a carbon source mixed solution; then add the carbon source mixed solution dropwise to the zirconium n-propoxide stirred at high speed In the mixture, stir for 2 days at 25°C and mix well. After 3 days of aging, a dark red gel is obtained, then dried in a drying oven at 80°C for 48 hours, and dry ground for 2 ...

Embodiment 3

[0042] (1) Dissolve 7g of sucrose in 50mL of solvent acetic acid at a temperature of 80°C, and cool the resulting solution to room temperature to obtain a carbon source solution (used as a carbon source); mix 8mL of zirconium n-propoxide with 8mL of diluent n-propanol After dilution, place it in a constant temperature water bath at 25°C and stir for 20 minutes, add 2 mL of chelating agent acetic acid to the mixed solution, and stir for 15 minutes to make it evenly mixed to obtain a zirconium n-propoxide mixed solution. Measure the carbon source solution according to the mass ratio of zirconium n-propoxide and sucrose as 12:4.6, and dilute it with 24mL of n-propanol to obtain a carbon source mixed solution; then add the carbon source mixed solution dropwise to the zirconium n-propoxide stirred at high speed In the mixture, stir at 30°C for 1 day and mix well. After 2 days of aging, a dark red gel is obtained, then dried in a drying oven at 80°C for 48 hours, and dry ground for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com