Method for synthesising In2Se3 (en) hollow nanospheres by means of hydrothermal method

A technology of hollow spheres and hydrothermal method, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems that there are no reports on nano-hollow spheres of indium selenide hybrid materials, and achieve a green and environmentally friendly preparation method. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Use an electronic balance to weigh 0.0663g (0.3 mmol) indium chloride and 0.0237g (0.3 mmol) selenium powder in a 25 ml reactor;

[0019] (2) Use a 5 ml pipette to accurately measure 4 ml of ethylenediamine, and a 10 ml pipette to accurately measure 10

[0020] ml of deionized water, accurately measure 3 ml of hydrazine hydrate into a 50 ml small beaker with a 5 ml pipette, and stir with a glass rod for 5 min to mix the three solutions evenly;

[0021] (3) Use a 25 ml graduated cylinder to measure 15 ml of the uniformly mixed solution in (2) into the reaction kettle in (1), and stir with a glass rod for 3 min to make it evenly mixed;

[0022] (4) Seal the reactor, put it in an oven at 180 °C for 24 h, cool it down to room temperature naturally, wash it with ethanol for 6 times, and dry it in a vacuum oven at 60 °C for 6 h to obtain yellow In 2 Se 3 (en) Nano hollow sphere powder.

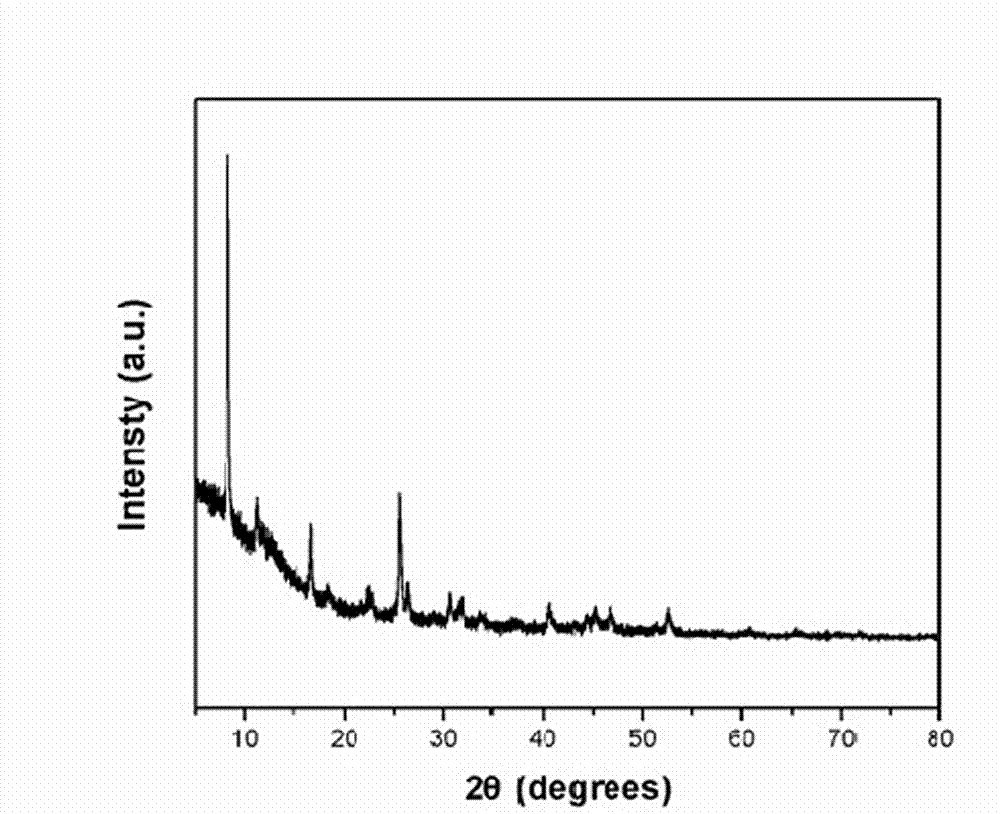

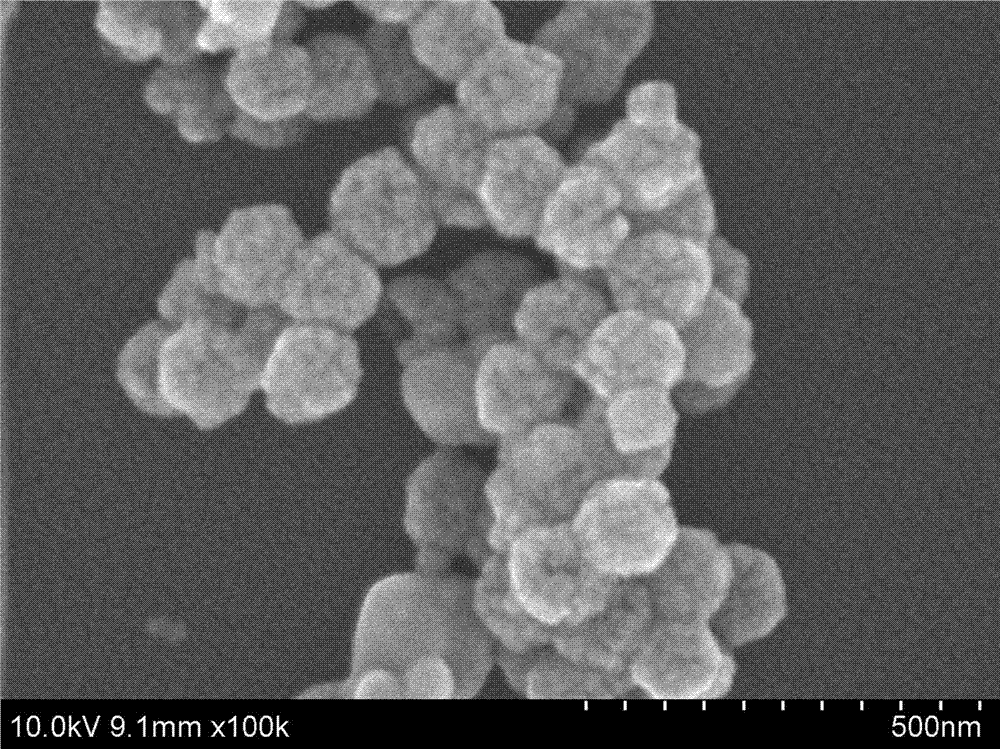

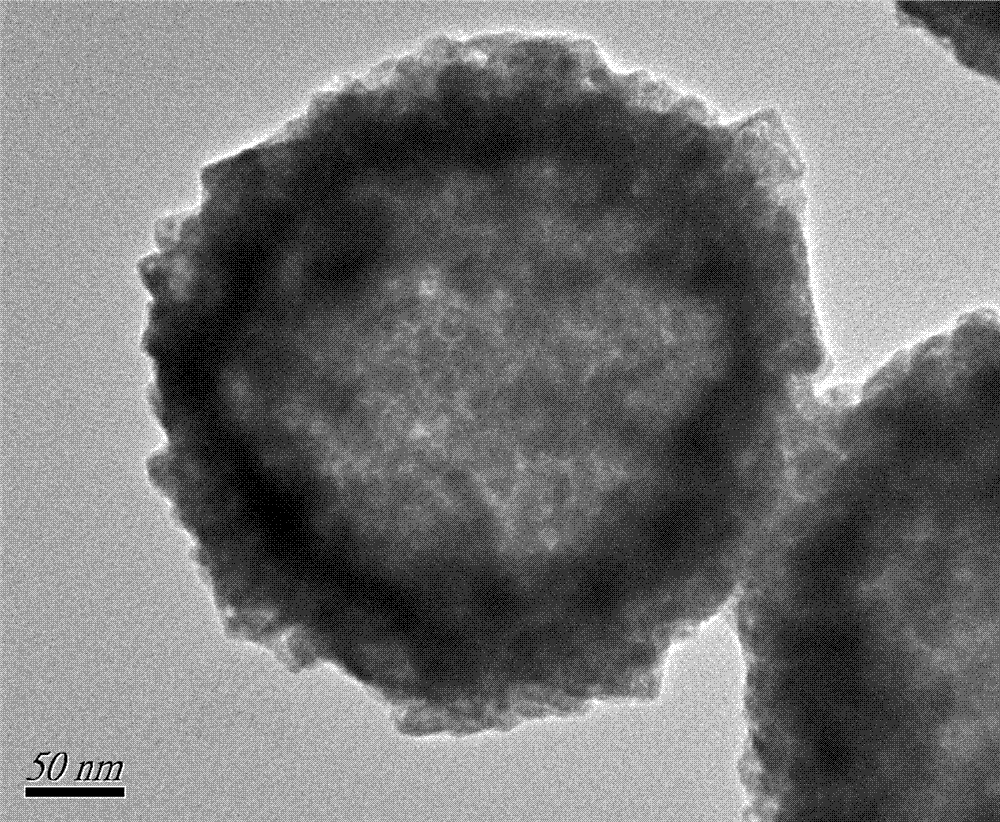

[0023] figure 1 is prepared in 2 Se 3 (en) XRD pattern of hollow nanospheres; ...

Embodiment 2

[0028] (1) Use an electronic balance to weigh 0.1065g (0.3 mmol) indium bromide and 0.0237g (0.3 mmol) selenium powder in a 25ml reactor;

[0029] (2) Use a 5 ml pipette to accurately measure 4 ml of ethylenediamine, a 10 ml pipette to accurately measure 10 ml of deionized water, and a 5 ml pipette to accurately measure 3 ml of hydrazine hydrate in 50 ml In a small beaker, stir with a glass rod for 5 min to mix the three solutions evenly;

[0030] (3) Use a 25 ml graduated cylinder to measure 15 ml of the uniformly mixed solution in (2) into the reaction kettle in (1), and stir with a glass rod for 3 min to make it evenly mixed;

[0031] (4) Seal the reaction kettle, put it in an oven at 180°C for 24 hours, cool it down to room temperature naturally, wash it with absolute ethanol for 6 times, and dry it in a vacuum oven at 60°C for 6 hours to obtain yellow In 2 Se 3 (en) Nano hollow sphere powder.

Embodiment 3

[0033] (1) Weigh 0.1146g (0.3 mmol) of indium nitrate and 0.0237g (0.3 mmol) of selenium powder into a 25 ml reaction kettle with an electronic balance;

[0034] (2) Use a 5 ml pipette to accurately measure 4 ml of ethylenediamine, a 10 ml pipette to accurately measure 10 ml of deionized water, and a 5 ml pipette to accurately measure 3 ml of hydrazine hydrate in 50 ml In a small beaker, stir with a glass rod for 5 min to mix the three solutions evenly;

[0035] (3) Use a 25 ml graduated cylinder to measure 15 ml of the uniformly mixed solution in (2) into the reaction kettle in (1), and stir with a glass rod for 3 min to make it evenly mixed;

[0036] (4) Seal the reaction kettle, put it in an oven at 180 °C for 24 h, cool it down to room temperature naturally, wash it with absolute ethanol for 6 times, and dry it in a vacuum oven at 60 °C for 6 h to obtain yellow In 2 Se 3 (en) Nano hollow sphere powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com