patterned sic substrate

A patterning and substrate technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problems affecting the crystallization quality of thin films and the inability to firmly bond substrates, etc., to reduce the linear dislocation density, Effects that improve performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

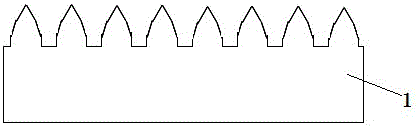

[0039] Such as Figure 5As shown, the pattern structure described in the embodiment of the present invention is a triangular pyramid, the bottom surface of the pattern is 2.4 μm in size, the distance between adjacent patterns is 0.6 μm, and the pattern height is 1.5 μm.

Embodiment 2

[0041] Such as Figure 6 As shown, the graphic structure described in the embodiment of the present invention is a spherical cap graphic, the size of the bottom surface of the graphic is 3.3 μm, the distance between adjacent graphics is 0.3 μm, and the graphic height is 1.2 μm.

Embodiment 3

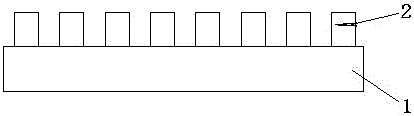

[0043] Such as Figure 7 As shown, the pattern structure described in the embodiment of the present invention is a cylindrical pattern, the bottom surface of the pattern is 1.2 μm in size, the distance between adjacent patterns is 1.1 μm, and the pattern height is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com