Metal film bridge igniter and preparation method thereof

A metal thin film and alloy thin film technology, applied in the field of electrical fireworks, can solve the problems of reducing the reliability level of the bridge wire igniter, affecting the ignition performance of the igniter, and the bridge wire igniter being unable to meet the requirements, so as to reduce the working energy. and ignition time, simple and reliable processing technology, and the effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

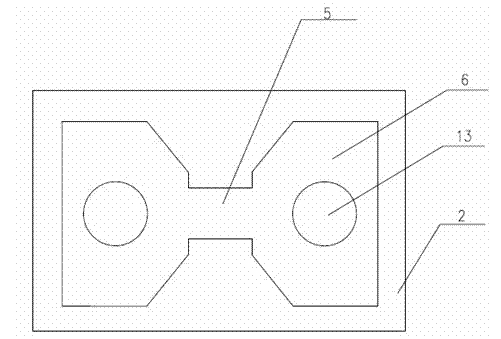

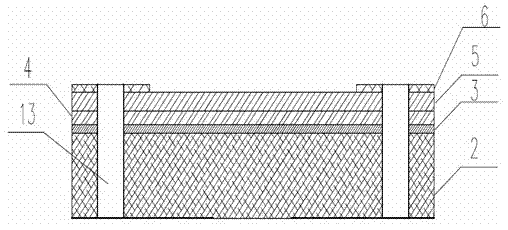

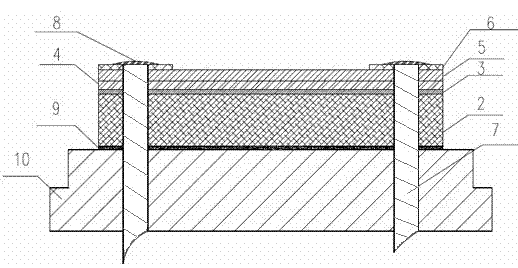

[0035] see Figure 1 to Figure 4 , the metal thin film bridge igniter 1 includes a substrate 2, a transition layer 3 disposed on the substrate 2, a thermal isolation film 4 disposed on the transition layer 3, a metal resistance film 5 disposed on the thermal isolation film 4, The electrode film 6 provided on the resistive film 5 is provided in the through hole 13 on the electrode film 6 .

[0036] Wherein, the material of the substrate 2 is polyimide, with a diameter of 100 mm to 400 mm and a thickness of 30 μm to 200 μm; the material of the transition layer 3 is Ta 2 o 5 , with a thickness of 0.05 μm to 0.1 μm; the material of the thermal isolation film 4 is SiO 2 , the thickness is 0.1 μm-1 μm, the material of the metal resistance film is Ni-Cr (8:2) alloy, the thickness is 0.2 μm-4 μm, the material of the electrode film 6 is Au, the thickness is 0.05 μm-0.1 μm.

Embodiment 2

[0038] The preparation method of the metal thin film bridge igniter comprises the following steps:

[0039](1) Clean the polyimide substrate with a diameter of 100mm to 400mm and a thickness of 30μm to 200μm to remove oil and impurities from the substrate;

[0040] (2) Put the substrate into the fixture, put it on the planet carrier of the coating system, and deposit Ta with a thickness of 0.05 μm to 0.1 μm on the surface of the substrate by means of ion beam sputtering deposition (PVD). 2 o 5 Transition layer film;

[0041] (3) Deposited by ion beam sputtering on Ta 2 o 5 Deposit SiO with a thickness of 0.1 μm to 1 μm on the surface of the transition layer film 2 thermal insulation film;

[0042] (4) Then deposited on SiO by ion beam sputtering 2 A Ni-Cr alloy film with a thickness of 0.2 μm to 4 μm is prepared on the surface of the thermal isolation film;

[0043] (5) Prepare a photoresist mask layer in the shape of a film bridge on the surface of the Ni-Cr alloy film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com