Surface treatment method for weldability and protectivity of aluminium alloy tube shell

A surface treatment, aluminum alloy technology, applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of easy corrosion of the tube shell, poor weldability of the coating, insufficient bonding force of the coating, etc., to achieve Effect of improving corrosion resistance, high bonding force of coating, and high protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

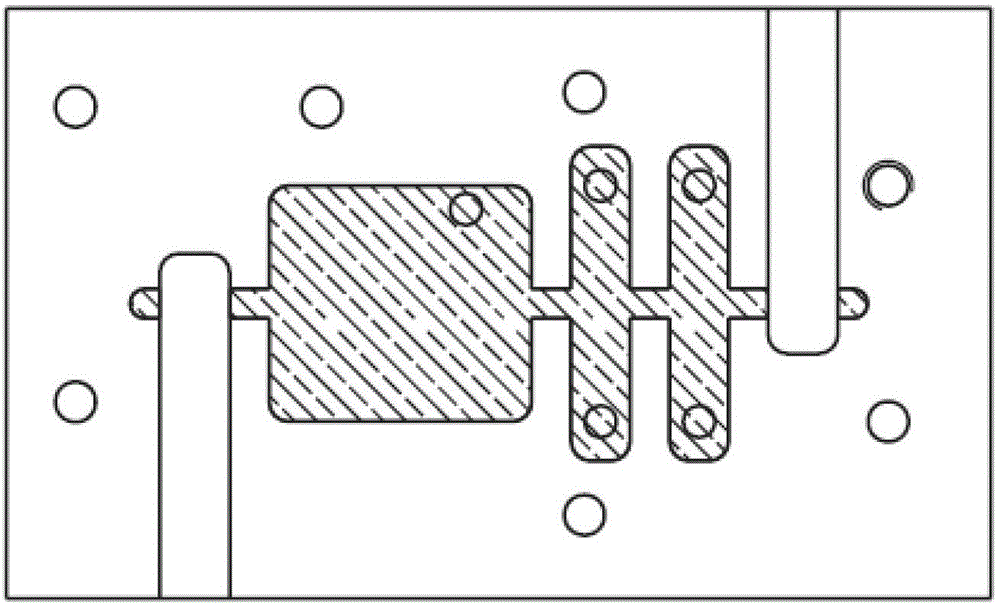

[0019] refer to figure 1 . According to the present invention, according to the solderability requirement, in the welding area of the aluminum alloy shell of the millimeter wave circuit assembly, the surface treatment area showing the silver plating range is filled with oblique lines. In the design drawing, the silver-plated part is filled with oblique lines to show Ep·Ni5~7, Ag7~9 (electroplated nickel 5~7μm silver 7~9μm), and the rest is chemically oxidized Ct.cd.O. The aluminum alloy may be an Al-Mg-based aluminum alloy or an Al-Mg-Si-based aluminum alloy.

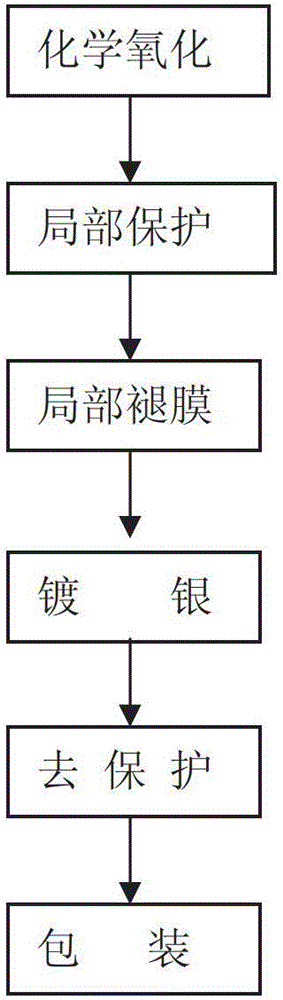

[0020] figure 2 Shown: In order to realize the weldability and protective treatment method of the aluminum alloy casing of the millimeter-wave circuit component described in the present invention, the technical solution includes the following steps: first, chemically oxidize the aluminum alloy casing, and then protect the aluminum alloy casing with electroplating protective glue. For the part to be plated, remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com