Two-dimensional electronic material device and mixed photoetching method thereof

A technology of two-dimensional electronics and mixed light, which is applied in the direction of circuits, electrical components, and electric solid-state devices, can solve problems affecting device performance, mobility degradation of two-dimensional electronic materials, and destruction of intrinsic characteristics of two-dimensional electronic materials. High lithography precision, improved lithography precision, and the effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

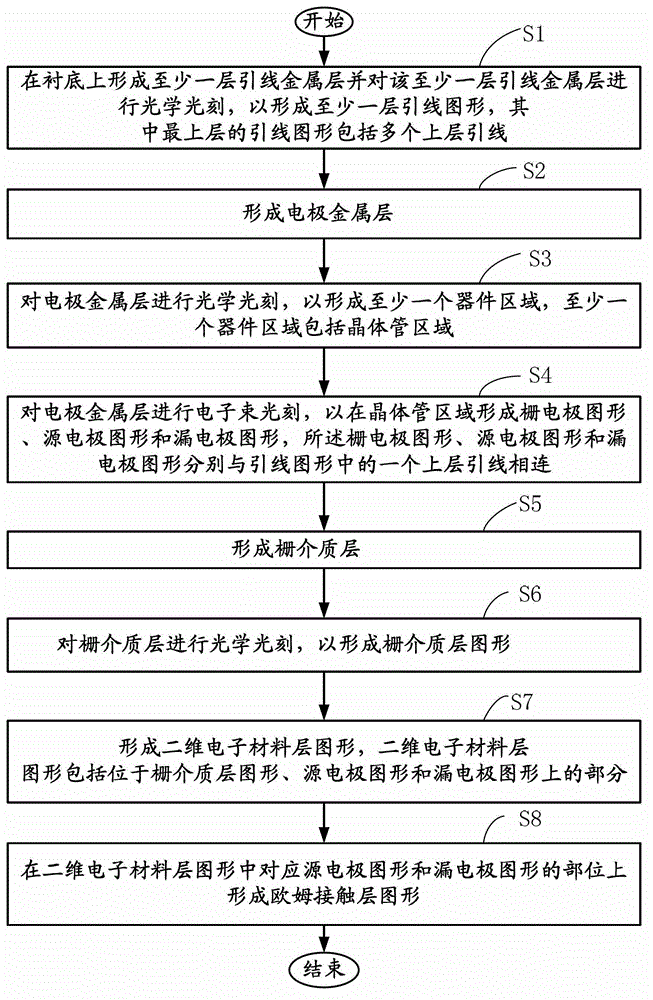

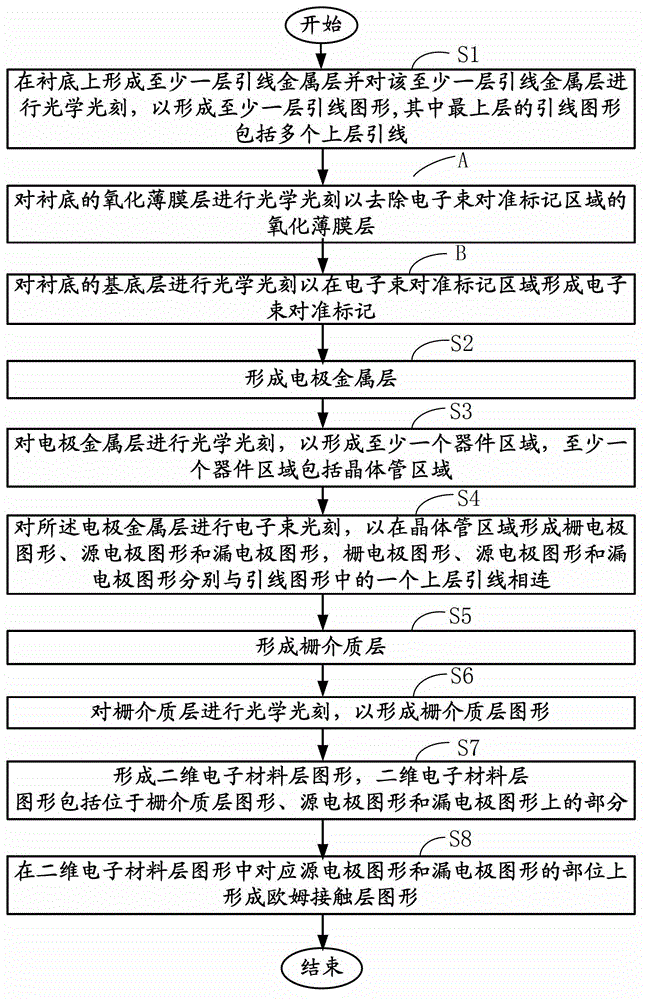

[0035] refer to figure 1 , the present invention provides a hybrid photolithography method for a two-dimensional electronic material device, an embodiment of which includes the following steps:

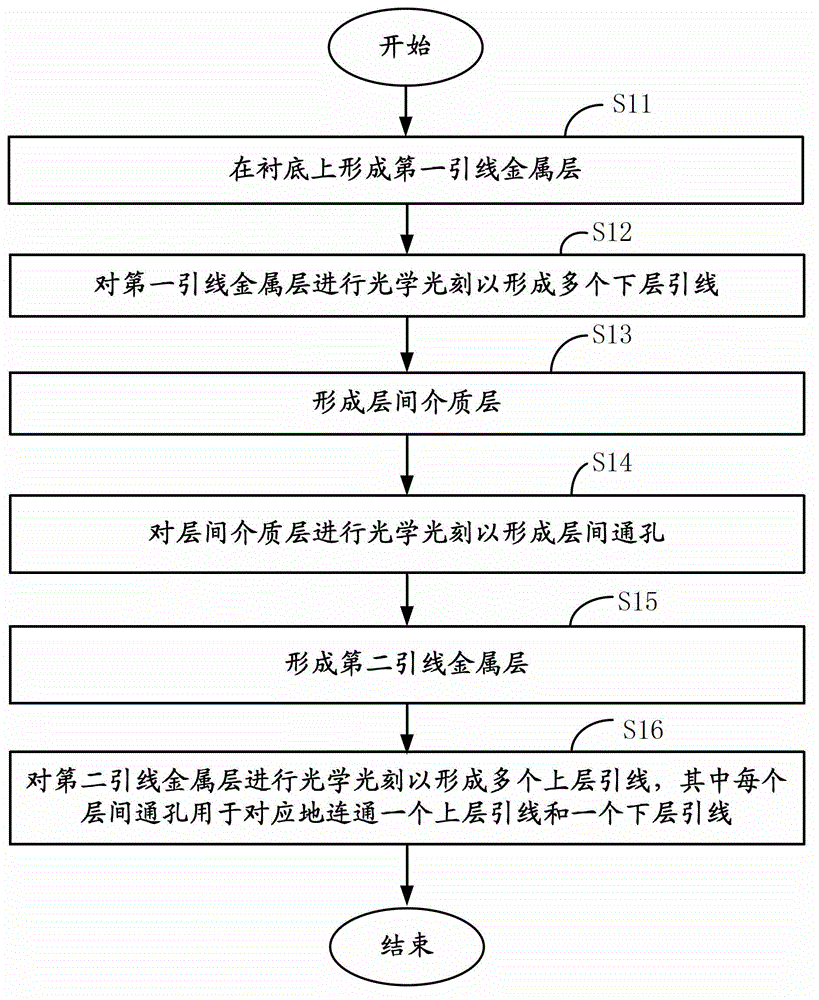

[0036] Step S1: forming at least one lead metal layer on the substrate and performing photolithography on the at least one lead metal layer to form at least one layer of lead pattern, wherein the uppermost lead pattern includes a plurality of upper layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com