Preparation method of LD steel cold roll ejector for small-pore stainless seamless pipe

A stainless steel, small aperture technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of difficult processing, low equipment requirements, slow processing speed, etc., to improve the processing yield, reduce equipment investment, and reduce processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

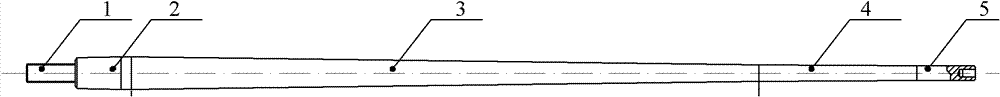

[0061] A steel pipe factory of an iron and steel company implements a method for preparing a small-aperture stainless steel seamless pipe LD steel cold-rolled plug provided by the present invention, which is used for cold-rolling LD steel of a certain type of stainless steel seamless pipe for nuclear power with a specification of 15*1.42 Plug machining, characterized in that it is composed of sawing machine, lathe, profiling lathe, cylindrical grinder, numerical control grinder, polishing and heat treatment process, namely:

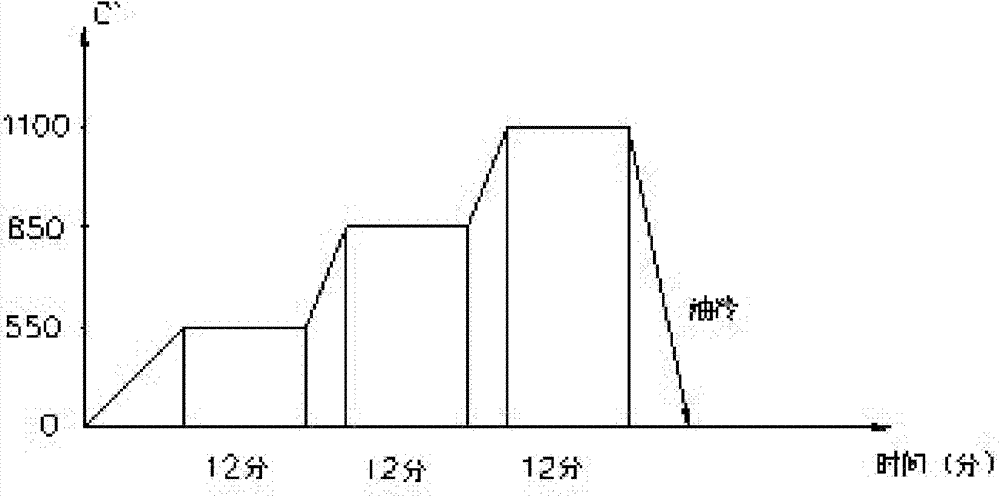

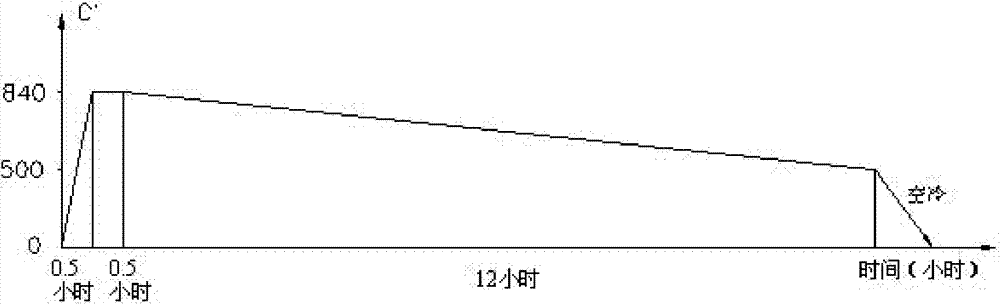

[0062] The processing technology model is: blanking (cutting length, sawing machine) → pre-heat treatment (stress relief annealing) → rough turning (shape forming, C6140 lathe) → semi-finishing turning (continuous curved surface profiling processing, C6140 lathe) → flattening ( Process flat body, B650 planer)→inspection (stamping)→heat treatment (1 time of quenching, 3 times of high temperature tempering, 1 time of partial annealing)→inspection (hardness, ...

Embodiment 2

[0082] A steel pipe factory of an iron and steel company implements a method for preparing a small-aperture stainless steel seamless pipe LD steel cold-rolled plug provided by the present invention, which is used for cold-rolling LD steel of a certain type of aviation stainless steel seamless pipe with a specification of 19*1.5 Plug machining, characterized in that it is composed of sawing machine, lathe, profiling lathe, cylindrical grinder, numerical control grinder, polishing and heat treatment process, namely:

[0083] The processing technology model is: blanking (cutting length, sawing machine) → pre-heat treatment (stress relief annealing) → rough turning (shape forming, C6140 lathe) → semi-finishing turning (continuous curved surface profiling processing, C6140 lathe) → flattening ( Process flat body, B650 planer)→inspection (stamping)→heat treatment (1 time of quenching, 3 times of high temperature tempering, 1 time of partial annealing)→inspection (hardness, curvature)...

Embodiment 3

[0102] A steel pipe factory of an iron and steel company implements a method for preparing a small-aperture stainless steel seamless pipe LD steel cold-rolled plug provided by the present invention, which is used for cold-rolling LD steel of a certain type of aviation stainless steel seamless pipe with a specification of 17*1.35 Plug machining, characterized in that it is composed of sawing machine, lathe, profiling lathe, cylindrical grinder, numerical control grinder, polishing and heat treatment process, namely:

[0103] The processing technology model is: blanking (cutting length, sawing machine) → pre-heat treatment (stress relief annealing) → rough turning (shape forming, C6140 lathe) → semi-finishing turning (continuous curved surface profiling processing, C6140 lathe) → flattening ( Process flat body, B650 planer)→inspection (stamping)→heat treatment (1 time of quenching, 3 times of high temperature tempering, 1 time of partial annealing)→inspection (hardness, curvature...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap