Composite flow baffling water treatment biomembrane reactor

A biofilm reactor and flow water treatment technology, applied in the field of water treatment, can solve the problems of many sludge outlets, large power consumption, and less biofilm, and achieve less sludge production, good hydraulic conditions, and convenient emptying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

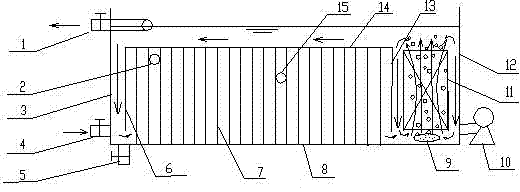

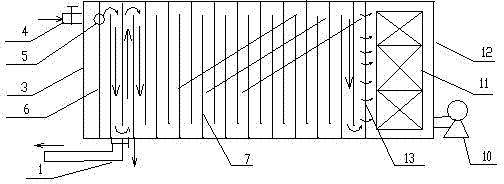

[0027] Such as figure 1 , 2 A compound baffle water treatment biofilm reactor shown in the figure is divided into an anoxic zone and an aerobic zone by an inflow partition 6, an outflow partition 13 and an advection plate 14 in a rectangular tank body. and the leveling zone, the top of the leveling plate 14 is the advection zone, the bottom is the anoxic zone, and the area on the right side of the outflow partition 13 is the aerobic zone.

[0028] The anoxic zone is surrounded by the horizontally arranged flow plate 14 and the vertically arranged inflow partitions 6 and outflow partitions 13 on both sides, forming a relatively independent semi-closed anoxic environment. Between the inlet partition 6 and the outlet partition 13, there are baffles 7 arranged in parallel, and the gap between adjacent baffles is 15 centimeters. The plate 14 is connected, and there is a gap between the dividing plate and the pool bottom plate 8, and the gap is 10 cm; the upper part of the baffle ...

Embodiment 2

[0050] Utilize this composite baffle water treatment biofilm reactor to treat nutrient-rich surface water, the gap between the adjacent baffles of the reactor is 30 cm, and the gap between the partition plate and the bottom plate 8 of the pool is 20 cm; the width of the baffle plate and the opposite surface The pool wall gap is 30 centimeters, the gap between the inlet partition 6 and the adjacent left pool wall 3 is 20 centimeters, the number of baffles is 28, and the aerobic zone is equipped with 9 groups of square vertical porous carriers 11, and the water depth in the advection zone is It is controlled at 1 / 5 of the water depth of the entire reactor; the area of the aerobic zone accounts for 1 / 3 of the pool body. Intermittent aeration and circulating water pump 10 are used for internal circulation. The concentration of ammonia nitrogen in the water is 3-10mg / L, and the concentration of total nitrogen is 5-20mg / L. Continuous operation is adopted, and the natural film-hangi...

Embodiment 3

[0052] Utilize this composite baffle water treatment biofilm reactor to process the aquaculture water in the soft-shelled turtle outer pond, the gap between the adjacent baffles of the reactor is 10 centimeters, and the gap between the dividing plate and the bottom plate 8 of the pond is 10 centimeters; The pool wall gap on the surface is 15 centimeters, the gap between the inlet partition 6 and the adjacent left pool wall 3 is 9 centimeters, the number of baffles is 15, and the aerobic zone carrier is equipped with 5 groups of square vertical porous carriers 11, advection The water depth of the zone is controlled at 1 / 4 of the water depth of the entire reactor; the area of the aerobic zone accounts for 1 / 4 of the pool body. Without aeration 9, only circulating water pump 10 is used for internal circulation. The concentration of ammonia nitrogen in the water is 1-10mg / L, and the concentration of total nitrogen is 2-32mg / L. Continuous operation is adopted, and the natural film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com