Method for utilizing pre-depositing magnetic separation combined technology to treat municipal wastewater

A technology for technical treatment and municipal sewage, applied in the field of municipal sewage treatment with pre-sedimentation combined with magnetic separation technology, can solve the problems of poor effluent quality, shortage of land, difficult land acquisition, etc., and achieve large hydraulic load, stable effluent quality, and separation speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

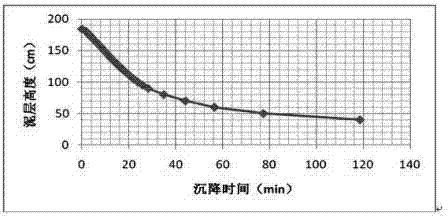

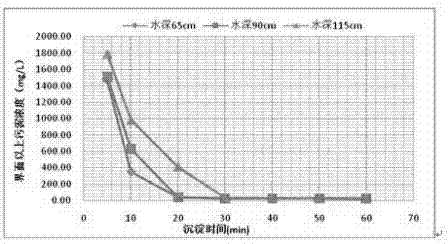

[0044] A municipal wastewater treatment project with a treatment scale of 25,000m 3 / d, the biochemical treatment is the oxidation ditch process, the sludge concentration of the oxidation ditch process is 3753 mg / L, the total phosphorus is 1.64 mg / L, and it flows into the pre-sedimentation system by gravity, and the surface hydraulic load of the pre-settling system is 2.4 m 3 / m 2 .h, the hydraulic retention time is 25min, the effluent sludge concentration of the pre-sedimentation system is 376mg / L, and the effluent sludge removal rate is 89.9%. The effluent from the pre-sedimentation system enters the magnetic separation system. Magnetic powder and micro-magnetic flocculation agents are added to the magnetic separation system successively to form flocs. After being separated by the magnetic separation wastewater purification system, the suspended solids in the effluent are 7 mg / L and the total phosphorus is 0.31 mg / L, the total phosphorus removal rate is 81.1%, and the efflu...

Embodiment 2

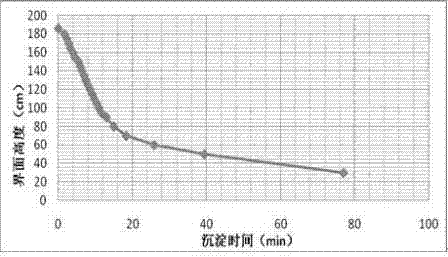

[0047] A municipal wastewater treatment project with a treatment scale of 48,000m 3 / d, the biochemical treatment is AAo (anaerobic-anoxic-aerobic method) process, the sludge concentration in the effluent of the biochemical treatment system is 2813mg / L, and the total phosphorus is 1.09mg / L. The waste water enters the pre-sedimentation system after biochemical treatment. The pre-sedimentation time of the pre-sedimentation system is 20 minutes, and the surface hydraulic load is 2.7m 3 / m 2 .h, the pre-settled effluent sludge concentration was 256 mg / L, and the effluent sludge removal rate was 90.9%. Then enter the magnetic separation system, add magnetic powder and micro-magnetic flocculation agent successively to form flocs, after being separated by the magnetic separation wastewater purification system, the effluent suspended matter is 8 mg / L, the total phosphorus is 0.27 mg / L, and the total The phosphorus removal rate is 75.2%, and the effluent is discharged after disinfect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com