Method for producing Nemadectin through fermenting

A technology of nimoctine and fermented liquid, which is applied in the field of microbial fermentation to produce antibiotics, can solve the problems that the synthesis process of fermented products is easily blocked and the strains are slow, and achieves the goals of simple and easy operation method, improved production level and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

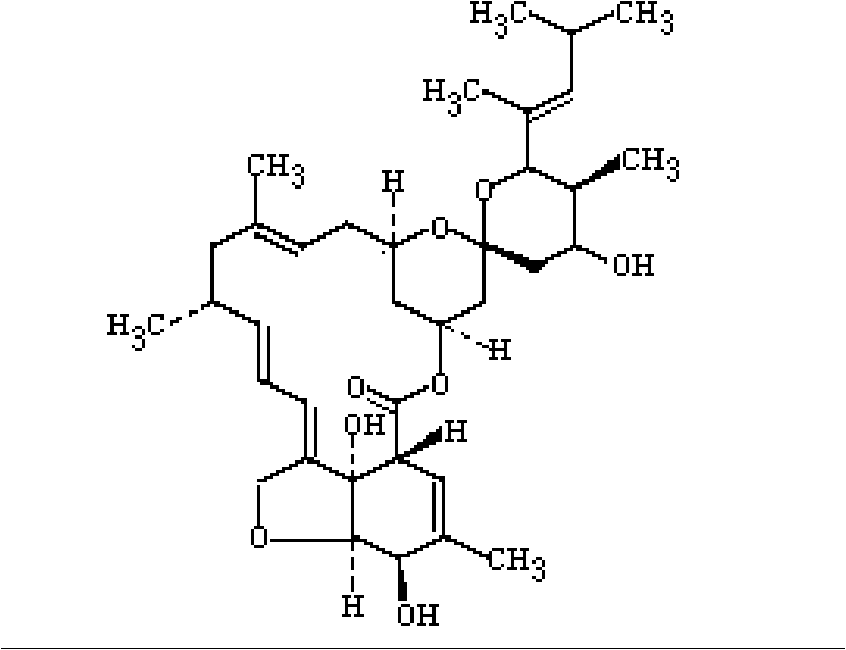

Image

Examples

Embodiment 1

[0021] Intermittent feeding in the fermentation process of embodiment 1 500L fermenter

[0022] Prepare 30L seed medium in a 50L seed tank, cool to 27-29°C after sterilizing at 120°C for 30min, insert 48h seed-age shake flask seeds according to 0.5% (volume ratio) inoculum, and then cultivate at 27-29°C for 28 -36h.

[0023] Prepare 350L fermentation medium in a 500L fermenter, cool to 27-29°C after sterilizing at 120°C for 30 minutes, insert the cultured seed medium according to 5% (volume ratio) inoculum, control the temperature at 27-27°C during the fermentation process 29°C, control the pressure at 0.04-0.06Mpa, control the ventilation and rotation speed according to the dissolved oxygen condition to ensure that the dissolved oxygen is above 30% (assuming that the initial dissolved oxygen of the fermenter is 100%), the ventilation is controlled at 0.5-1VVM, and the rotation speed is controlled at 120-250rpm, add ammonia water and 10% dilute sulfuric acid to control the pH...

Embodiment 2

[0024] Continuous feeding in the fermentation process of embodiment 2 5000L fermenter

[0025] Prepare 300L seed culture medium in a 500L seed tank, cool to 27-29°C after sterilizing at 120°C for 30 minutes, insert 48h seed-age shake flask seeds according to 0.5% (volume ratio) inoculum, and then cultivate at 27-29°C for 28 -36h.

[0026] Prepare 3500L fermentation medium in a 5000L fermenter, sterilize at 120°C for 30 minutes, then cool to 27-29°C, insert the seed medium at 5% (volume ratio) inoculum, control the temperature at 27-29°C during the fermentation process, Control the pressure at 0.04-0.06Mpa, control the ventilation and rotation speed according to the dissolved oxygen condition to ensure that the dissolved oxygen is above 30% (assuming that the initial dissolved oxygen of the fermenter is 100%), the ventilation is controlled at 0.5-1VVM, and the rotation speed is controlled at 90-180rpm. During the cultivation process, ammonia water and 10% dilute sulfuric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com