Nanofiber laminate sheet

A technology of nanofibers and composite nanofibers, applied in the field of layered sheets, can solve problems such as difficulty in pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

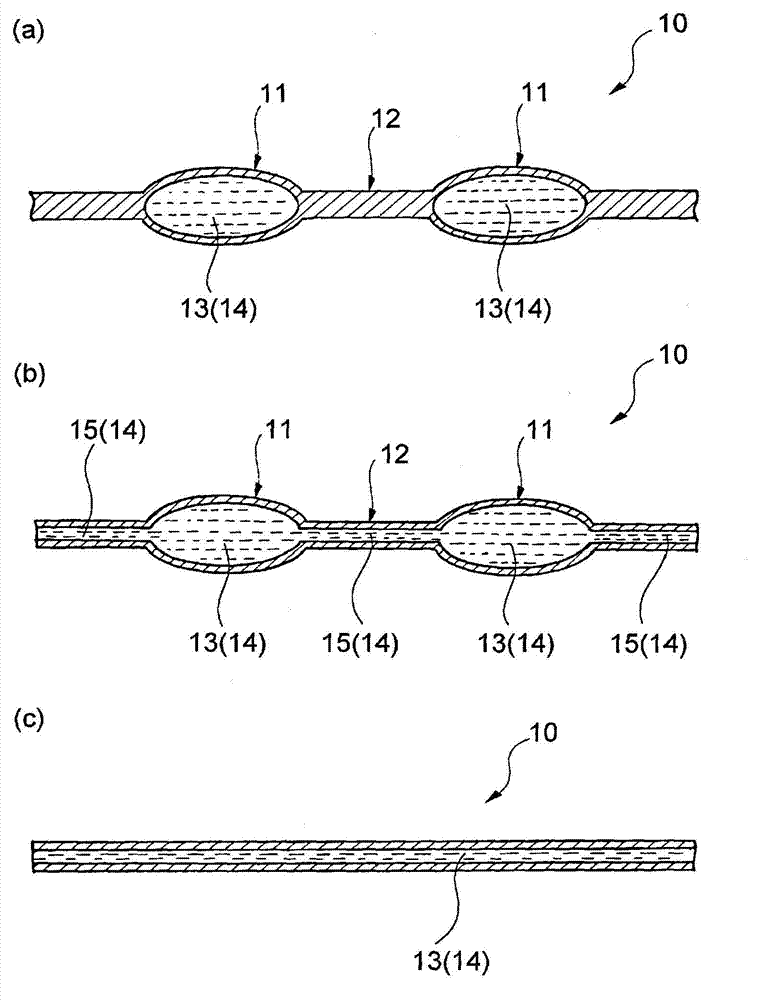

[0095] Hereinafter, the present invention will be described based on preferred embodiments. The nanofiber laminated sheet (hereinafter also referred to as "laminated sheet") of the first embodiment has a layer of nanofibers of a water-insoluble polymer compound (hereinafter also referred to as "water-insoluble nanofiber layer") and a water-soluble polymer compound layer ((hereinafter also referred to as "water-soluble layer") as its basic structure. The water-soluble layer is arranged on one side of the water-insoluble nanofiber layer. It is suitable to arrange the water-soluble layer adjacent to the water-insoluble nanofiber layer Of course, depending on the specific application of the laminate, layers different from these layers can also be arranged between the water-insoluble nanofiber layer and the water-soluble layer.

[0096]The water-insoluble nanofiber layer is preferably composed of only nanofibers containing a water-insoluble polymer compound (hereinafter, the nanofi...

no. 2 Embodiment approach 〕

[0144] The embodiment described above is a laminated form of a water-insoluble nanofiber layer and a water-soluble layer, but other embodiments of the present invention include water-insoluble nanofibers and water-soluble nanofibers containing the aforementioned active ingredients. Embodiments of Nanofibrous Sheets. Hereinafter, the nanofiber sheet of this embodiment will be described. Regarding this nanofiber sheet, unless otherwise specified, the description regarding the laminated sheet of the first embodiment described above applies. The nanofiber sheet of the second embodiment has a single-layer basic structure. From the viewpoint that the structure of the nanofiber sheet can be sufficiently ensured even after the water-soluble nanofiber dissolves in water and disappears, the proportion of the water-insoluble nanofiber in the nanofiber sheet of the second embodiment is preferably 20 to 90% by mass, especially It is 30 to 90% by mass. On the other hand, the proportion o...

Embodiment 1

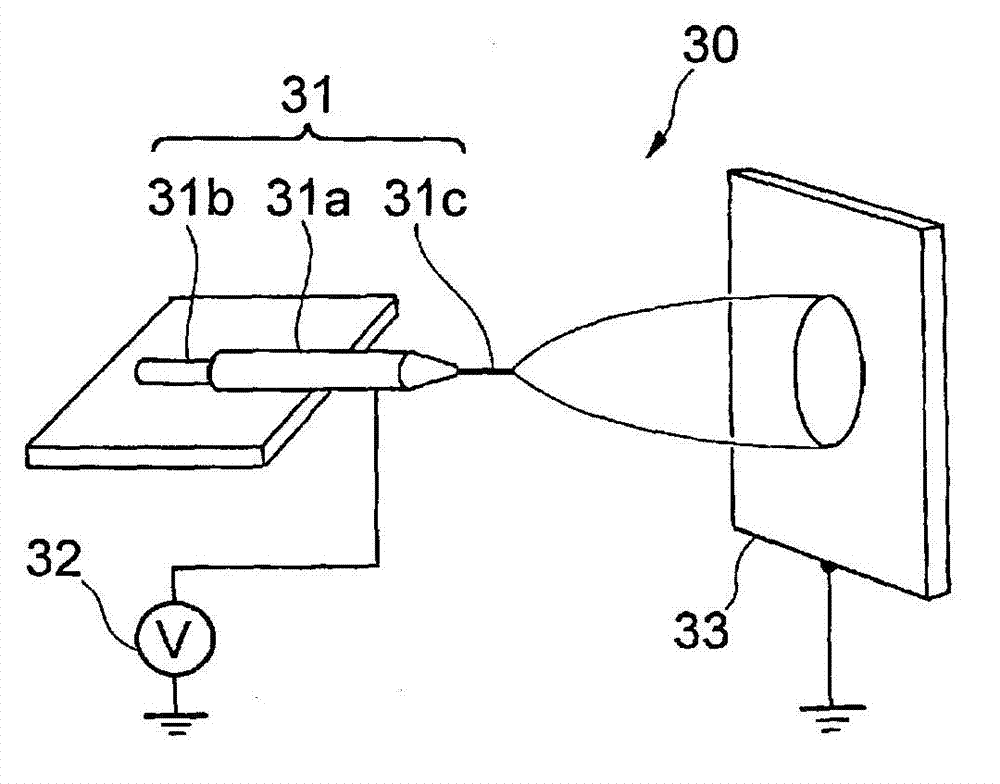

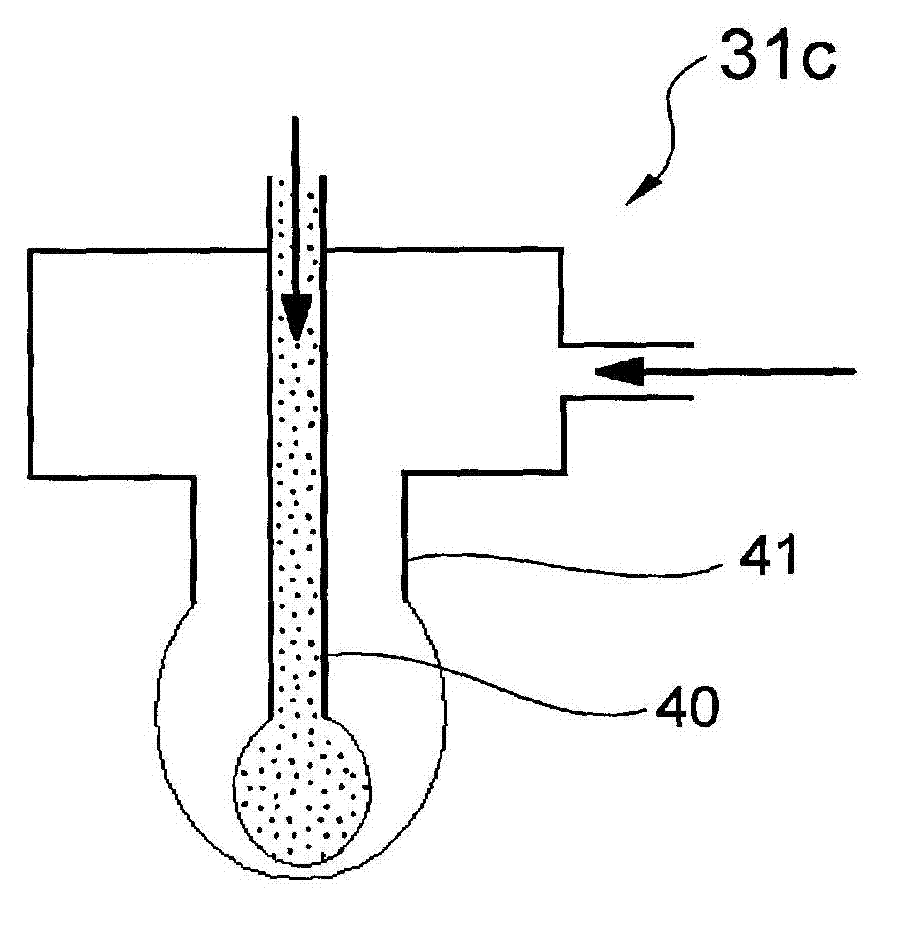

[0226] As the water-insoluble compound, polyvinyl butyral (trade name BM-1) manufactured by Sekisui Chemical Co., Ltd. was used. It was dissolved in an ethanol solution, adjusted to a concentration of 15%, and used as a spray liquid for the electrospinning method. Use this spray liquid, with figure 2 The shown device performs electrospinning to form each on the surface of a polyethylene terephthalate mesh (Volteing Crosteron T-No. 100T, TOKYO SCREEN CO., LTD) disposed on the surface of the current collector 33. Square meter unit weight 5g / m 2 layer of water-insoluble nanofibers. The conditions of the electrospinning method were set as follows.

[0227] · Applied voltage: 26kV

[0228] ·Distance between capillary and current collector: 120mm

[0229] ·Spray volume of aqueous solution: 1.0ml / h

[0230] ·Environment: 26℃, 40%RH

[0231] Next, Hayashibara Shoji pullulan was used as a water-soluble compound. This was dissolved in warm water at 80° C. to obtain an aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com