Preparation method of pumpkin dietary fiber and pumpkin dietary fiber

A dietary fiber and pumpkin technology, which is applied in the field of enzymatic preparation of pumpkin dietary fiber, can solve the problems such as no technical reports on pumpkin dietary fiber, and achieve the effect of rich functional substances, simple operation steps, and good cholesterol adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

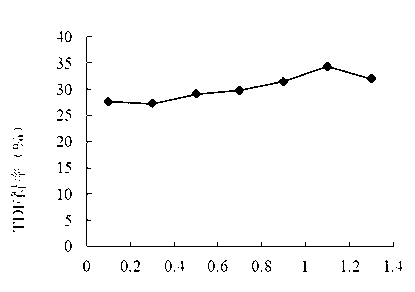

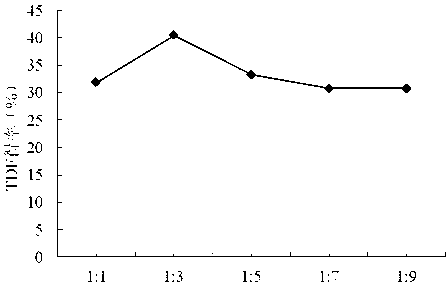

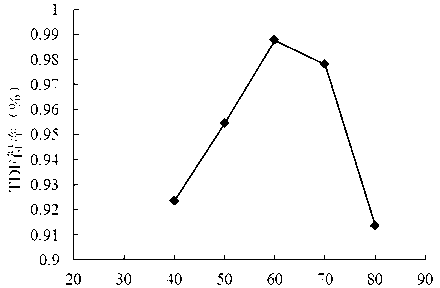

[0056] Example 1 Raw material formula and process single factor research experiment of pumpkin fiber preparation

[0057] α-amylase can hydrolyze starch in pumpkin raw materials into dextrin and oligosaccharides, and glucoamylase can specifically hydrolyze dextrin and oligosaccharides into glucose and dissolve in organic solvents. Therefore, the present invention intends to use α-amylase and glucoamylase to hydrolyze pumpkin. However, the effect of enzymatic hydrolysis to remove starch is not only closely related to the type of enzyme, but also to the amount of each enzyme added, the total amount of mixed enzymes added, the ratio of various enzymes in the mixed enzyme, the time of enzymatic hydrolysis, and the amount of enzyme added. The solution temperature and other factors are closely related, and there are interaction effects between these factors, and the mechanism of action is relatively complicated. At the same time, the operation result of the enzymatic starch hydr...

Embodiment 2

[0066] Example 2 Optimization of preparation process of pumpkin dietary fiber

[0067] On the basis of the single factor test, in order to obtain the best process for preparing dietary fiber, the present invention has selected the amount of mixed enzyme added, the time of enzymolysis of mixed enzyme, the ratio of mixed enzyme, the amount of added protease, and the time of enzymatic hydrolysis of protease to carry out further normalization. In this experiment, the effects of these five factors on the preparation of pumpkin dietary fiber were comprehensively investigated, and the evaluation results were expressed by the yield of total dietary fiber (TDF) of pumpkin. Use L 16 (4 5 ) Orthogonal test table (shown in Table 2) to test and determine the best combination.

[0068]

[0069] Orthogonal experiment results of optimization of pumpkin dietary fiber preparation process

[0070] The experimental results were analyzed by SPSS. From the results of the variance analysis t...

Embodiment 3

[0083] Pumpkin dietary fiber is prepared by the following preparation method in the present embodiment:

[0084] (1) Take fresh pumpkin, wash, peel and remove seeds, and use a tissue masher to mash the pumpkin pulp;

[0085] (2) Add 0.2M phosphate buffer with a pH value of 6 to the mashed pumpkin pulp, and the mass ratio of pumpkin pulp to phosphate buffer is 1:6;

[0086] The composition of phosphate buffer is: 1L phosphate buffer contains 123ml of 0.2M disodium hydrogen phosphate, 877ml of 0.2M sodium dihydrogen phosphate;

[0087] (3) Add mixed enzyme to the pumpkin pulp mixed with phosphate buffer in step (2), the amount of mixed enzyme added is determined according to 0.5% of the total weight of phosphate buffer and pumpkin pulp; α-amylase and saccharification in the mixed enzyme The weight ratio of the enzyme is 1:7 (that is, α-amylase and glucoamylase are 216 U / g and 2398 U / g respectively), enzymolysis at 60°C for 90 minutes, boiling to kill the enzyme, cooling to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com