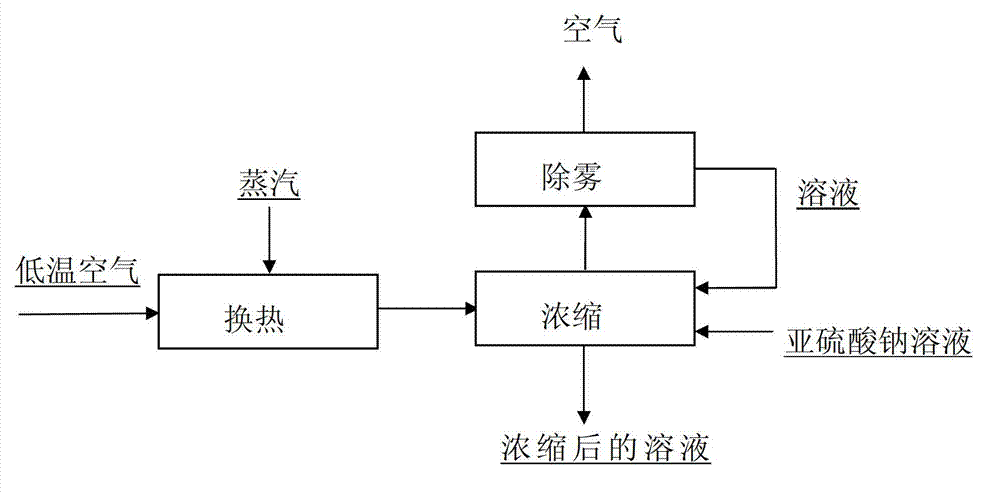

Evaporation and concentration process of sodium sulfite solution

A technology of evaporation concentration and sodium sulfite, which is applied in the direction of preparation, evaporation, chemical instruments and methods of alkali metal sulfite, can solve the problems of reducing product recovery rate and a large number of heat sources, and achieve good product quality, good operating flexibility, and energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

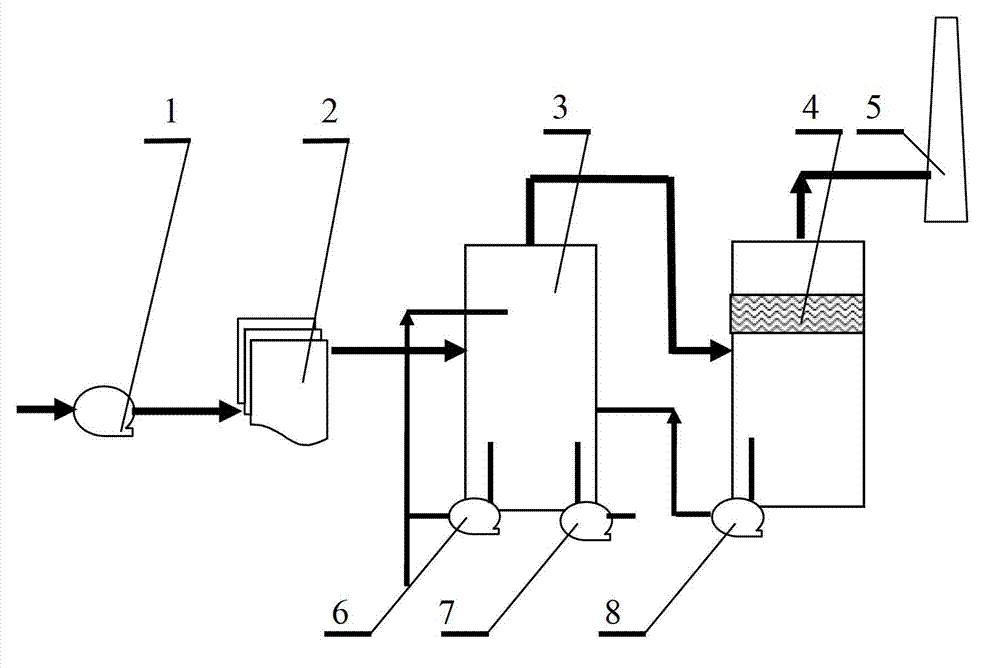

Embodiment 1

[0026] In this embodiment, the blower 1 is used to blow the low-temperature air into the heat exchanger 2 to exchange heat with saturated steam at a pressure of 4.5 kg. Generate hot air at 110°C, pass it into the concentration tank 3, and make countercurrent contact with the saturated sodium sulfite solution circulated by the circulation pump 6 in the concentration tank 3, and volatilize the moisture in the sodium sulfite solution into the hot air to form a 70°C saturated Humid air, saturated humid air enters the demist tower 4, and the solution entrained in the saturated humid air is removed through the fiber demister in the demist tower 4, and the solution is sent to the concentration tank 3 by the condensate pump 8 for re-concentration. The saturated humid air after defogging is emptied through the chimney 5. When the concentration of the sodium sulfite solution in the concentration tank 3 reaches a certain concentration, it is then transported to the cooling crystallizatio...

Embodiment 2

[0028] In this embodiment, the blower 1 is used to blow the low-temperature air into the heat exchanger 2 to exchange heat with saturated steam at a pressure of 12.5 kg. Generate hot air at 150°C, pass it into the concentration tank 3, and make downstream contact with the saturated sodium sulfite solution circulated by the circulation pump 6 in the concentration tank 3, volatilize the water in the sodium sulfite solution into the hot air, and form a temperature of 72°C Saturated humid air, saturated humid air enters the demist tower 4, in the demist tower 4, the solution entrained in the saturated humid air is removed through the wire mesh demister, and the solution is sent to the concentration tank 3 through the condensate pump 8 for re- The concentrated and demisted saturated air is emptied through the chimney 5. When the concentration of the sodium sulfite solution in the concentration tank 3 reaches a certain concentration, it is then transported to the cooling crystalliza...

Embodiment 3

[0030] In this embodiment, the blower 1 is used to blow the low-temperature air into the heat exchanger 2 to exchange heat with saturated steam at a pressure of 25 kg. Generate hot air at 220°C, pass it into the concentration tank 3, and make countercurrent contact with the saturated sodium sulfite solution circulated by the circulation pump 6 in the concentration tank 3, and volatilize the moisture in the sodium sulfite solution into the hot air to form 80°C saturated Humid air, saturated humid air enters the demist tower 4, in the demist tower 4, the solution entrained in the saturated humid air is removed through the baffle demister in the demist tower 4, and the solution is sent to the concentration tank 3 through the condensate pump 8 for re- The concentrated, demisted saturated humid air is emptied through the chimney 5. When the concentration of the sodium sulfite solution in the concentration tank 3 reaches a certain concentration, it is then transported to the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com