Energy-saving evaporation treatment process of high-salinity wastewater

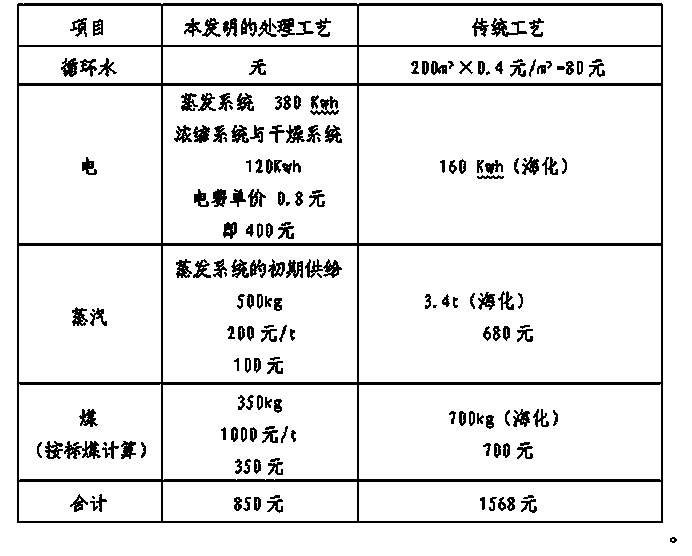

A high-salt wastewater treatment technology, applied in the direction of heating water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high production cost, difficult to meet the waste water standard, difficult to effectively use, etc. Achieve the effects of small footprint, short processing flow and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

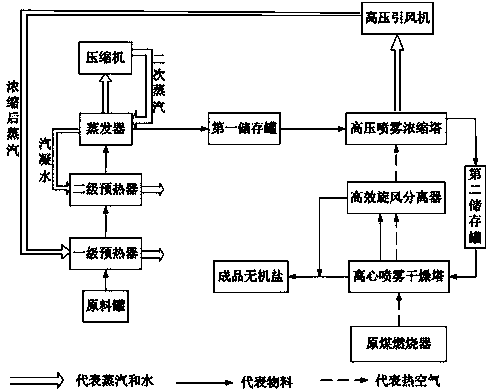

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Taking the wastewater containing ammonium chloride produced in the production process of potassium dihydrogen phosphate as an example, the specific treatment process is as follows:

[0046] ① Evaporation system: 500kg of ammonium chloride wastewater with a concentration of 10% ammonium chloride treated by the sewage treatment system is passed into the raw material tank, and then sent to the primary preheater and secondary preheater in turn for graded preheating , after graded preheating, it is transported to the evaporator, and heated and evaporated at 30°C to obtain an ammonium chloride evaporation liquid with a concentration of 25%;

[0047] ② Concentration system: The ammonium chloride evaporation liquid enters the first storage tank and is stored after being removed by the adsorption layer. The adsorption layer is supported by the upper and lower grid plates. The activated coal gangue in the adsorption layer weighs 5kg. The stored ammonium chloride evaporat...

Embodiment 2

[0053] Embodiment 2 Taking the wastewater containing sodium chloride produced in the epoxy resin production process as an example, the specific treatment process is as follows:

[0054] ① Evaporation system: 1 ton of sodium chloride wastewater with a sodium chloride concentration of 18% treated by the sewage treatment system is passed into the raw material tank, and then sent to the primary preheater and secondary preheater in turn for graded preheating , after graded preheating, it is transported to the evaporator, and heated and evaporated at 100°C to obtain a sodium chloride evaporation liquid with a concentration of 35%;

[0055] ② Concentration system: The sodium chloride evaporation liquid enters the first storage tank and is stored after being removed by the adsorption layer. The adsorption layer is supported by upper and lower grid plates. The activated coal gangue in the adsorption layer weighs 20kg. The stored sodium chloride evaporates The liquid is transported to t...

Embodiment 3

[0061] Embodiment 3 Taking the waste water containing calcium chloride produced in the sodium dichloroisocyanurate production process as an example, the specific treatment process is as follows:

[0062] ① Evaporation system: 2 tons of calcium chloride wastewater with a calcium chloride concentration of 14% treated by the sewage treatment system is passed into the raw material tank, and then sent to the primary preheater and secondary preheater in turn for graded preheating , after graded preheating, it is transported to the evaporator, and heated and evaporated at 65°C to obtain a calcium chloride evaporation liquid with a concentration of 30%;

[0063] ②Concentration system: Calcium chloride evaporation liquid enters the first storage tank and is stored after being removed by the adsorption layer. The adsorption layer is supported by upper and lower grid plates. The activated coal gangue in the adsorption layer weighs 30kg. The stored calcium chloride evaporates The liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com