Environment-friendly antimicrobial odorless latex paint

An antibacterial coating and environmentally friendly technology, applied in latex paint, antifouling/underwater coating, coating, etc., can solve the problems of large particle aggregation, poor dispersion, and increased coating cost, achieve high surface finish, improve adhesion The effect of strong force and high hiding power of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

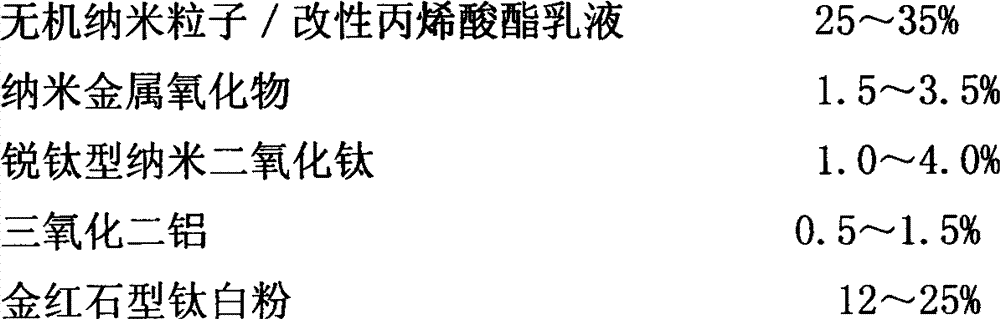

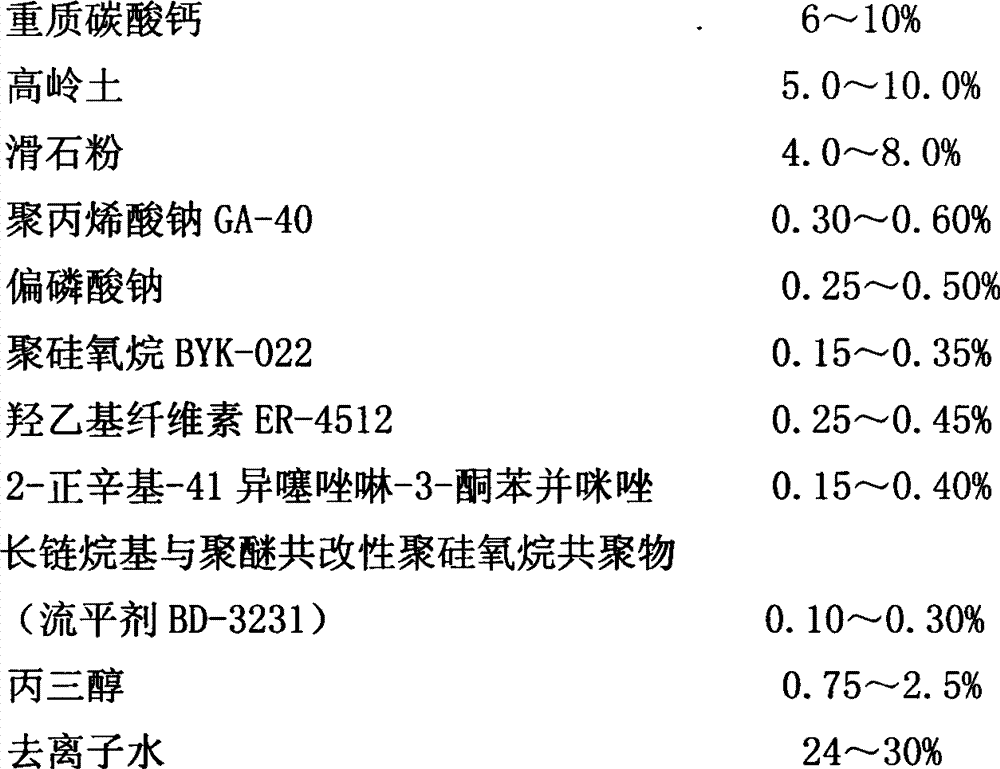

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation of environment-friendly type antibacterial net odor latex paint, comprises the following steps:

[0027] (1) Take 0.60 kg of sodium polyacrylate (GA-40) and 0.50 kg of sodium metaphosphate and disperse them in 27.5 kg of deionized water, add 1.0 kg of nano-zinc oxide, 1.2 kg of nano-copper oxide, and 1.0 kg of anatase nano-titanium dioxide under high-speed stirring. kg and 0.5 kg of aluminum oxide, mixed for 1 hour.

[0028] (2) Slowly add 25 kg of rutile titanium dioxide, 6 kg of heavy calcium carbonate, 5 kg of kaolin, 5 kg of talcum powder, 2-n-octyl-41 isothiazole 0.25 kg of lin-3-one benzimidazole, 0.8 kg of glycerol, 0.1 kg of polysiloxane (BYK-022), 0.25 kg of hydroxyethyl cellulose (ER-4512), and stir at high speed for 0.5 hours.

[0029] (3) Slowly add 35 kg of inorganic nano-titanium dioxide / organic silicon-acrylate composite emulsion, 0.25 kg of BD-3231 leveling agent and 0.15 kg of remaining polysiloxane (BYK-022), hydroxyl Ethyl cell...

Embodiment 2

[0031] A kind of preparation of environment-friendly type antibacterial net odor latex paint, comprises the following steps:

[0032] (1) Take 0.40 kg of sodium polyacrylate (GA-40) and 0.30 kg of sodium metaphosphate and disperse them in 28 kg of deionized water, add 1.0 kg of nano-zinc oxide, 1.0 kg of nano-silver oxide, and 2.0 kg of anatase nano-titanium dioxide under high-speed stirring. kg and 0.5 kg of aluminum oxide, mixed for 1 hour.

[0033] (2) Under medium-speed stirring, slowly add 18 kg of rutile titanium dioxide, 9 kg of heavy calcium carbonate, 5 kg of kaolin, 4 kg of talcum powder, 2-n-octyl-41 isothiazole Lin-3-one benzimidazole 0.40 kg, glycerol 2.5 kg, polysiloxane (BYK-022) 0.15 kg, hydroxyethyl cellulose (ER-4512) 0.15 kg, high-speed stirring for 0.5 hours.

[0034] (3) Slowly add 27 kg of inorganic nano-silica / organic silicon-acrylate composite emulsion, 0.30 kg of BD-3231 leveling agent and 0.2 kg of the remaining polysiloxane (BYK-022) to the material...

Embodiment 3

[0036] A kind of preparation of environment-friendly type antibacterial net odor latex paint, comprises the following steps:

[0037](1) Take 0.50 kg of sodium polyacrylate (GA-40) and 0.25 kg of sodium metaphosphate and disperse them in 30 kg of deionized water, add 1.0 kg of nano-zinc oxide, 1.0 kg of nano-silver oxide and 1.0 kg of nano-copper oxide under high-speed stirring, 1.5 kilograms of anatase nano-titanium dioxide and 0.5 kilograms of aluminum oxide were mixed for 0.75 hours.

[0038] (2) Under medium-speed stirring, slowly add 15.5 kg of rutile titanium dioxide, 7 kg of heavy calcium carbonate, 8 kg of kaolin, 7 kg of talcum powder, and 2-n-octyl-41 isothiazole to the material of (1). 0.30 kg of lin-3-one benzimidazole, 0.75 kg of glycerol, 0.15 kg of polysiloxane (BYK-022), 0.15 kg of hydroxyethyl cellulose (ER-4512), and stir at high speed for 0.5 hours.

[0039] (3) Slowly add 25 kg of inorganic nano-zirconia / organic silicon-acrylate composite emulsion, 0.10 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com