Symmetrical capacitor pressure sensor and manufacture method thereof

A pressure sensor and capacitive technology, which is applied in fluid pressure measurement, instruments, and force measurement using capacitance changes. It can solve problems such as large parasitic capacitance and difficult control of pressure-sensitive film processing thickness, so as to avoid stress and ensure long-term stability. Consistency of performance and performance, and the effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

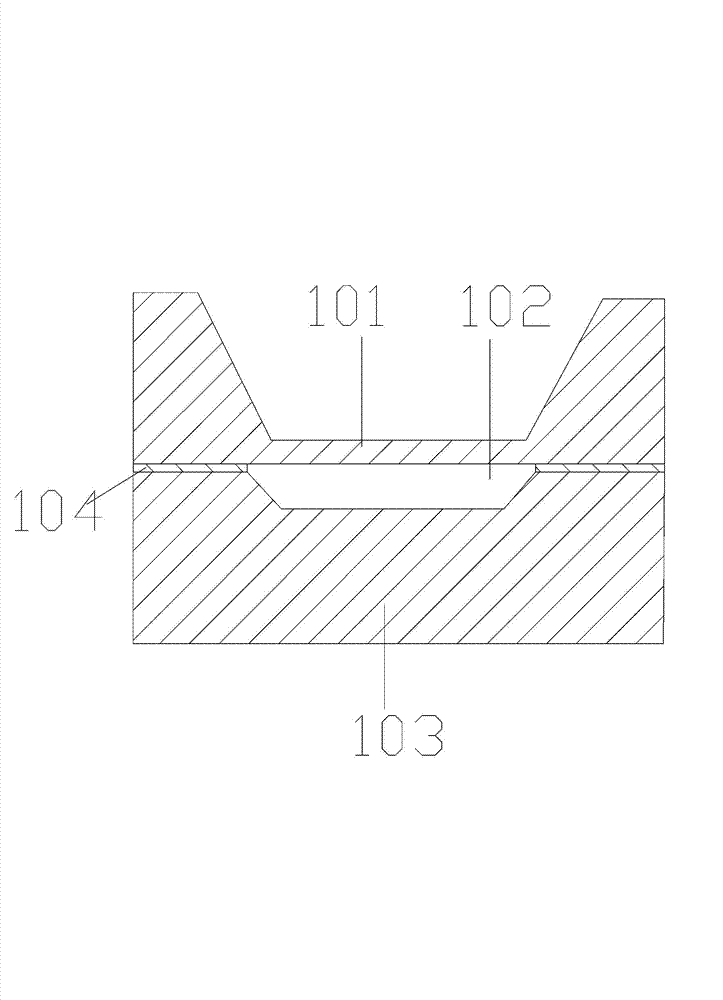

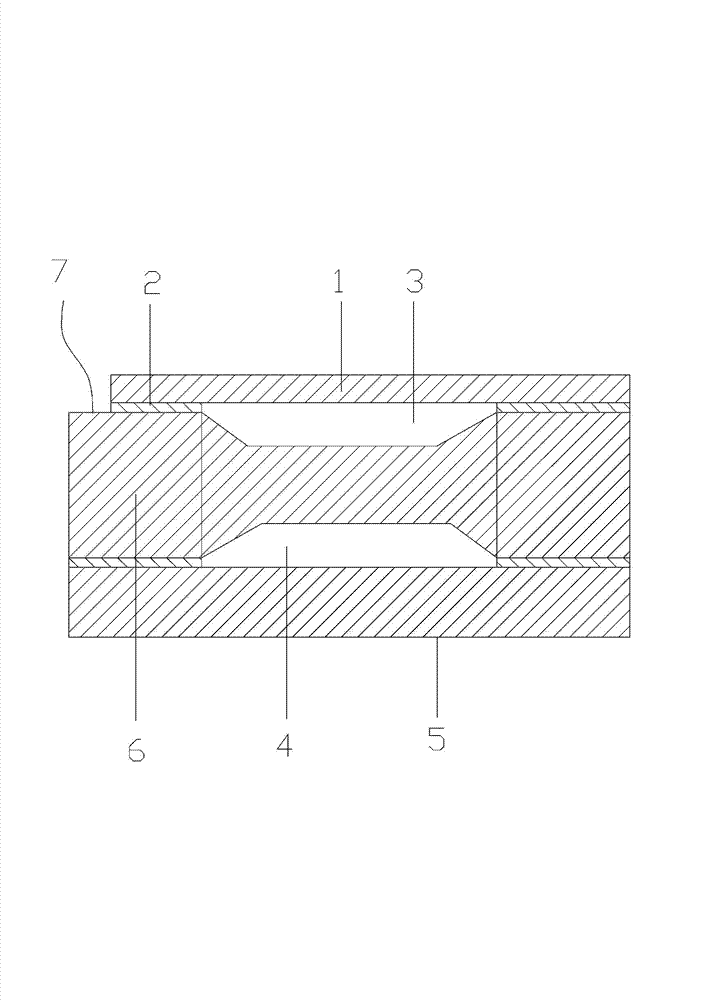

[0028] One, such as figure 2 , image 3 As shown, a symmetrical capacitive pressure sensor provided by the present invention includes: a substrate 6 made of silicon wafers, two sides of the substrate 6 are respectively provided with completely symmetrical detection capacitance chambers 3 and reference capacitance chambers 4, and the back of the substrate 6 is bonded to silicon. The cover plate 5 and the substrate 6 are bonded on the front side to the pressure sensitive membrane 1 made of SOI silicon wafer, and the substrate on one side of the pressure sensitive membrane 1 is provided with an electrode 7 .

[0029] 2. A method for preparing a symmetrical capacitive pressure sensor, which uses the existing MEMS bulk silicon technology to process and manufacture, and the specific process steps are:

[0030] (1) The substrate 6 is made of silicon wafers. After the silicon wafers are cleaned, they are oxidized to form SO 2 Isolation layer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com