Preparation method for microwave device with gradient refractive indexes based on mixed liquid medium

A gradient-refractive-index, microwave device technology is applied in the field of preparation of gradient-refractive-index microwave devices, which can solve the problems of difficulty in practical application, limited refractive index variation range, complicated manufacturing process, etc. The effect of wide tuning range and wide range of refractive index distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Further, the preparation method of the gradient index microwave device based on the mixed liquid medium comprises the following steps:

[0053] 1) Determine the spatial distribution diagram of the refractive index according to the electromagnetic wave operating frequency band and radiation characteristics of the gradient-refractive-index microwave device, and perform discrete processing on the obtained spatial distribution diagram of the refractive index according to the size of the corresponding discrete unit to obtain each discrete unit layer The equivalent electromagnetic wave refractive index;

[0054] 2) According to the results of discrete processing, using photocuring rapid prototyping technology, using liquid photocuring resin as raw material, adopting layered photocuring method to prepare the resin frame structure of gradient index microwave devices;

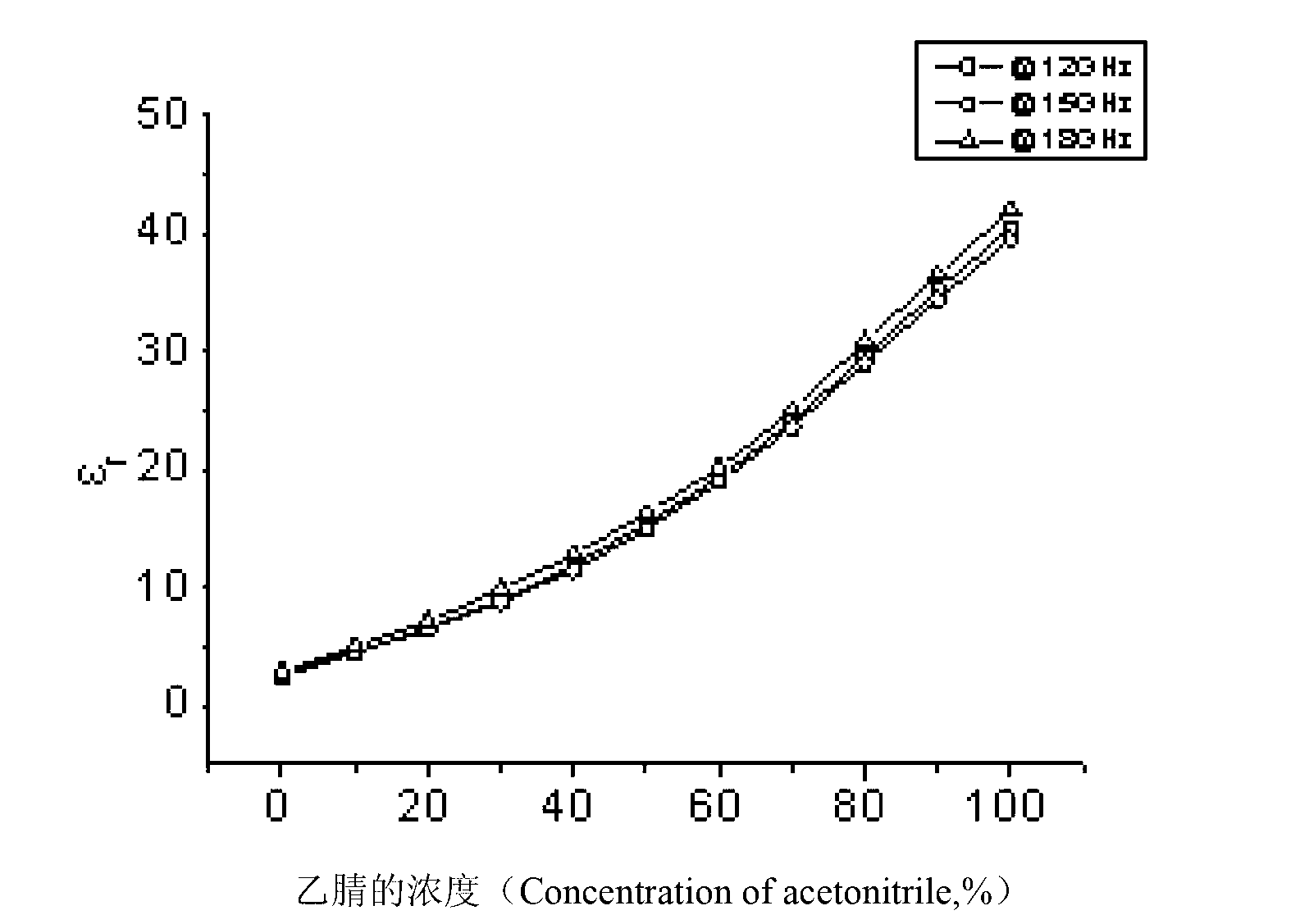

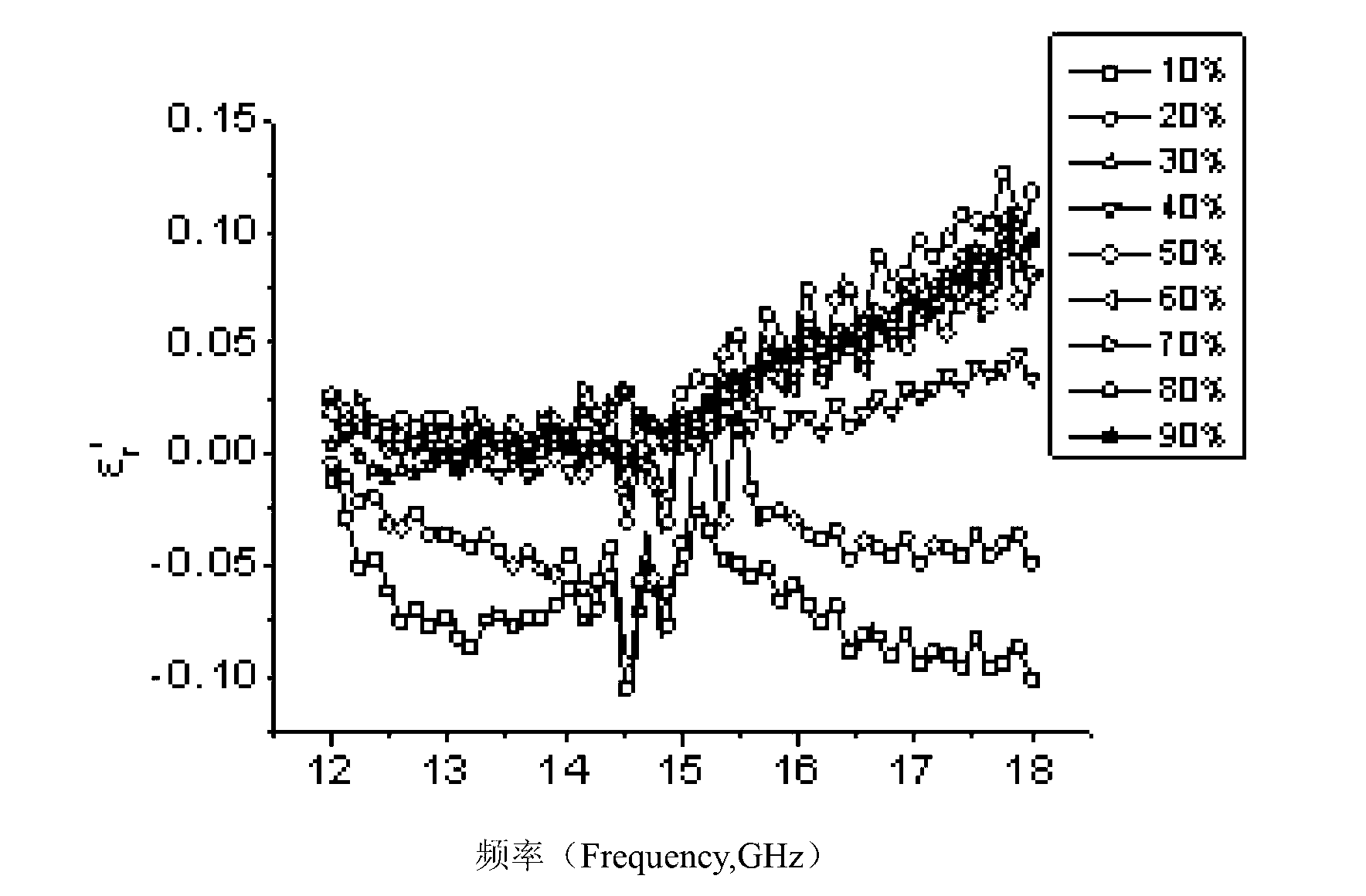

[0055] 3) Mix non-magnetic liquids with different electromagnetic wave refractive indices, and obtain mixed li...

Embodiment 1

[0063] A new binary mixed liquid material based on benzene and acetonitrile was prepared, and the mixed liquid medium was used to realize the fabrication of a broadband gradient index plane lens with the function of scanning the electromagnetic beam direction, which specifically includes the following steps:

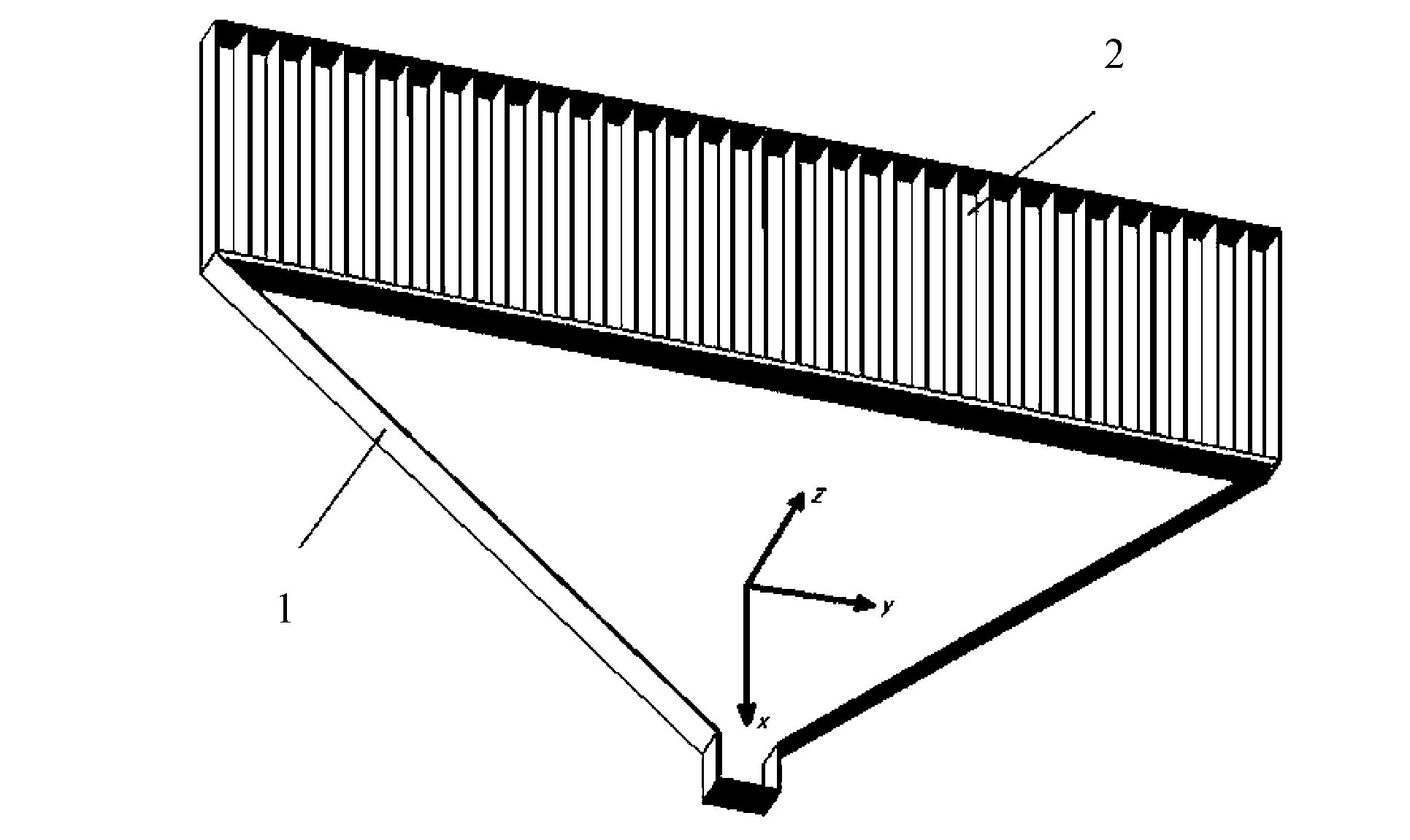

[0064] 1) Reference image 3 (Where, 1 is the resin frame, 2 is the injected mixed liquid medium), the flat antenna lens is symmetrical about the x-axis, the length of the lens is 250.8mm, the width is 60.8mm, the signal source is placed at a distance of 125.4mm from the lens, and the lens antenna The thickness of the resin frame is 0.3mm, and the working frequency range is 12~18GHz;

[0065] 2) From the lens size in step 1) and the relationship between the phase of the electromagnetic wave and the refractive index in the medium, the distribution equation of the electromagnetic wave refractive index (along the y direction) on the lens plane can be obtained as:

[0066] ...

Embodiment 2

[0075] The design of binary mixed liquid medium of benzene and acetonitrile realizes the fabrication of wide-angle and wide-band planar Lunberg lens, which specifically includes the following steps:

[0076] 1) Reference Figure 4 (wherein, 1 is the resin frame, and 2 is the injected mixed liquid medium). The shape of the new planar Lunberg lens is similar to a planar helmet, and its bottom is a flat plate. Theoretically, when the dielectric constant of the medium is from 17.5 to 1. When the impedance is continuously changed and matched at the edge of the lens, all plane waves of different angles incident on the front will converge on the bottom plate after passing through the lens. The length of the bottom plate of the lens is 107.2mm. The maximum size is 140mm.

[0077] 2) Mix analytically pure (AR) benzene and acetonitrile according to a certain ratio, and perform magnetic stirring in a water bath at 60°C for 15 minutes to make them evenly mixed;

[0078] 3) The dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com