Slushing agent for concrete and preparation method thereof

A technology of concrete water reducing agent and hydrogen peroxide, applied in the field of concrete additives, can solve the problems of reducing concrete quality, excessive slump loss, poor slump retention ability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to the present invention, the present invention also provides the preparation method of the above-mentioned concrete water reducing agent, comprising the following steps:

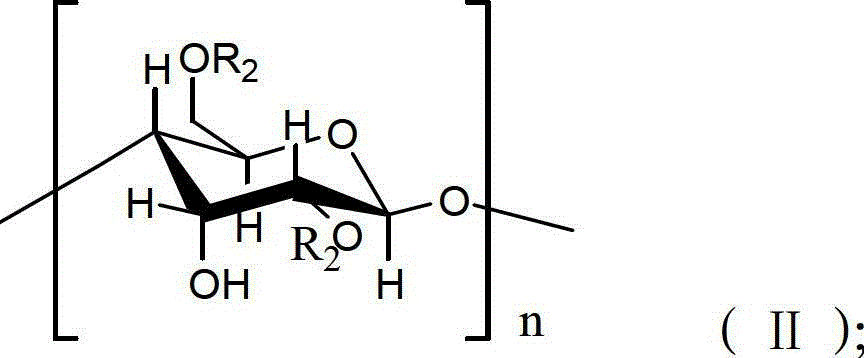

[0034] Under the catalysis of acetate, maleic anhydride and hydroxypropyl methylcellulose are reacted for the first time in glacial acetic acid to obtain hydroxypropylmethylcellulose monomaleate;

[0035] Free radical polymerization of methallyl polyoxyethylene ether, acrylic acid solution and the hydroxypropyl methylcellulose monomaleate under a redox initiation system to obtain a concrete water reducer.

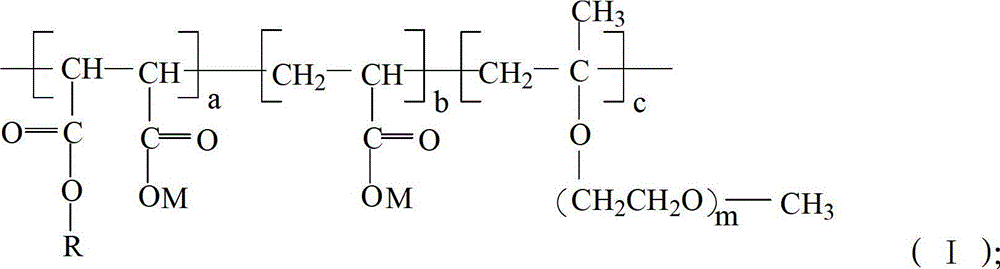

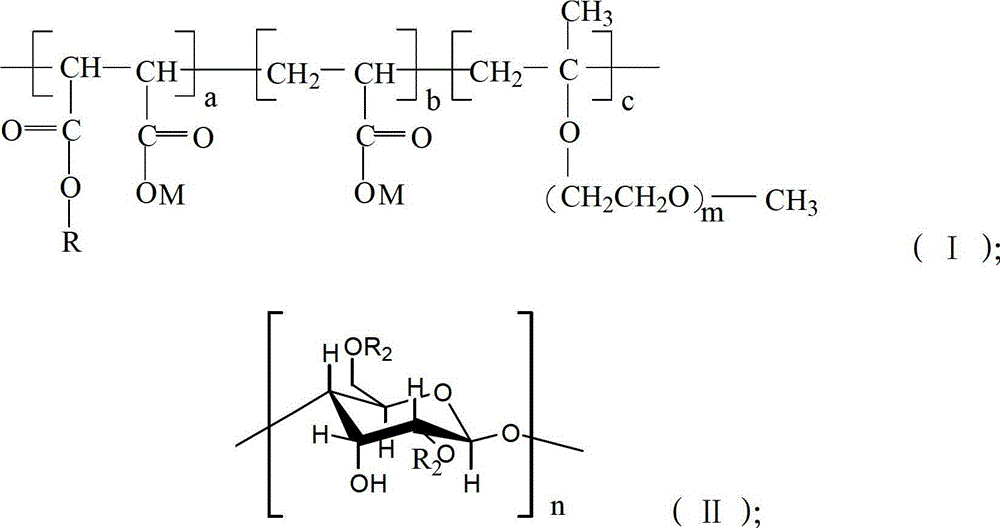

[0036] In the process of preparing the concrete water reducer, the present invention first uses maleic anhydride to modify hydroxypropyl methylcellulose to prepare hydroxypropyl methylcellulose monomaleate monomer, and then hydroxypropyl methylcellulose Free radical polymerization of methyl cellulose monomaleate, methallyl polyoxyethylene ether and acrylic acid to obtain polyether concre...

Embodiment 1

[0047] Example 1 Preparation of hydroxypropylmethylcellulose monomaleate (MAPMC) monomer

[0048] In a dry round bottom flask equipped with a reflux condenser, add 80ml of glacial acetic acid and 2.5g of pre-dried hydroxypropylmethylcellulose (HPMC), control the temperature at 90°C, and stir for 1h. After heating up to the desired temperature, 5.0 g of maleic anhydride and 1.2 g of anhydrous sodium acetate were added. After incubation for 5 hours, terminate the reaction with 30ml of deionized water, then add 3ml of concentrated hydrochloric acid, and shake well. Slowly pour the reactants into a large amount of excess 60°C deionized water while stirring mechanically to obtain a white flocculent polymer. The polymer was filtered with a filter cloth, and the product was washed with deionization at 60°C until neutral. Vacuum-dry the washed product at about 50°C and pulverize to obtain hydroxypropylmethylcellulose monomaleate (MAPMC).

Embodiment 2

[0050] 8.5g of acrylic acid and 1.5g of water were made into monomer aqueous solution, 0.3g of mercaptoacetic acid, 0.1134g of ascorbic acid and 27.6g of water were made into initiator water solution for later use; 71.5g of TPEG2400, 0.4g MAPMC, 0.3g hydrogen peroxide (30wt%) and 85.6g deionized water, heated and stirred to 45°C. Use a constant flow pump to control the dropping time according to a certain dropping rate, and drop the acrylic acid monomer mixed aqueous solution and the initiator mixed aqueous solution within 3.0 hours and 3.5 hours respectively at a constant speed. After the initiator was added dropwise, the insulation reaction was carried out for 1.5h. After the reaction, cool naturally, and adjust the pH value to 6~7 with 60g of 40% NaOH solution to obtain MAPMC modified polyether water reducer PC01 with a solid content of about 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com