Polyoxyethane ether-based glycerol phosphite polymer, preparation method for same and near-dry cutting fluid prepared from same for gear machining

A technology based on glyceryl phosphite and glyceryl phosphite, which is applied in quasi-dry cutting fluid for gear processing, polyoxyethylene ether-based glyceryl phosphite polymer and its preparation, can solve the problems affecting the health of operators and processing Site and environmental pollution, large amount of lubricant used, etc., to achieve good water solubility, good extreme pressure and anti-wear properties, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

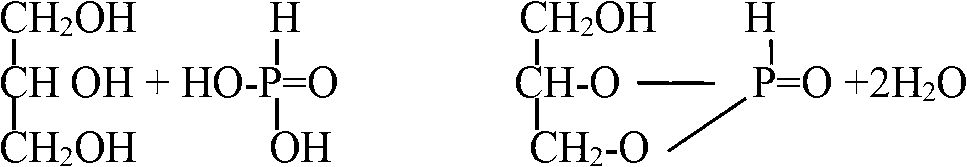

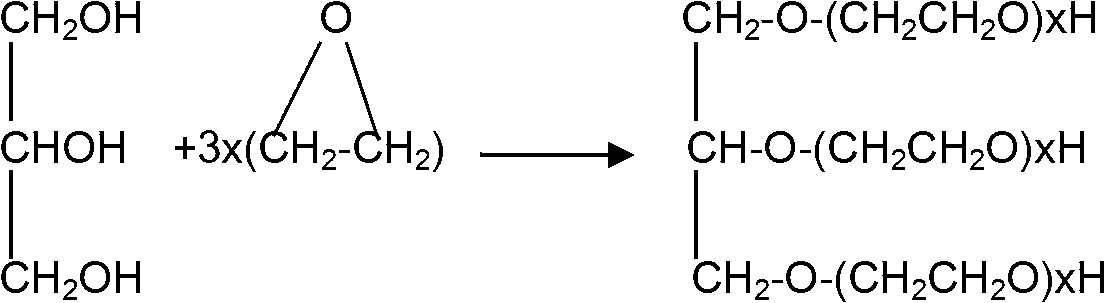

[0038] Step 1: Weigh 92.09kg (1000mol) of glycerin and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, heat and stir to 130°C, keep stirring at constant temperature for 4 hours, discharge the water generated by the reaction under reduced pressure, and prepare phosphorous acid Glyceride A 142kg (1000mol) for standby (the yield of the product in actual production is less than 100%, so the actual obtained phosphite glyceride is less than 1000mol);

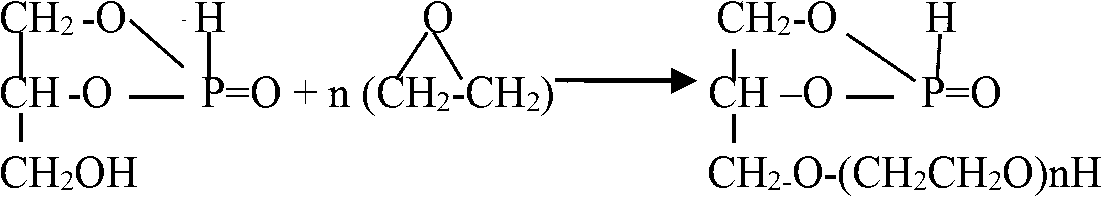

[0039] Step 2: Add 142kg (1000mol) of phosphite glyceride A and 5.15kg of potassium hydroxide prepared in step 1 into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, then pass into the polymerization kettle into the nitrogen conversion kettle Air, when the nitrogen in the polymerization kettle maintains a positive pressure, use a nitrogen feed tank to push 881kg (20000mol) of ethylene oxide into the polymerization kettle, while stirring to raise the te...

Embodiment 2

[0044] Step 1: Weigh 92.09kg (1000mol) of glycerin and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, heat and stir to 140°C, keep stirring at a constant temperature for 3 hours, discharge the water generated by the reaction under reduced pressure, and prepare phosphorous acid Glyceride A 142kg (1000mol) for standby (the yield of the product in actual production is less than 100%, so the actual obtained phosphite glyceride is less than 1000mol);

[0045] Step 2: Add 142kg (1000mol) of phosphite glyceride A and 7kg of potassium hydroxide prepared in step 1 into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, then feed nitrogen into the polymerization kettle to change the air in the kettle , when the nitrogen in the polymerization kettle maintains a positive pressure, use a nitrogen feed tank to push 660.75kg (15000mol) of ethylene oxide into the polymerization kettle, while stirring to raise th...

Embodiment 3

[0050] Step 1: Weigh 92.09kg (1000mol) of glycerin and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, heat and stir to 135°C, keep stirring at a constant temperature for 3.5 hours, discharge the water generated by the reaction under reduced pressure, and prepare phosphorous acid Glyceride A 142kg (1000mol) for standby (the yield of the product in actual production is less than 100%, so the actual obtained phosphite glyceride is less than 1000mol);

[0051]Step 2: Add 142kg (1000mol) of phosphite glyceride A and 4.5kg of potassium hydroxide prepared in step 1 into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, and then pass into the polymerization kettle into the nitrogen conversion kettle Air, when the nitrogen in the polymerization kettle maintains a positive pressure, push 440.5kg (10000mol) of ethylene oxide into the polymerization kettle with a nitrogen feed tank, while stirring and raisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com