Epoxy/organosilicon co-curing composite material for LED packaging and preparation method

A technology of LED packaging and composite materials, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as high tension and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

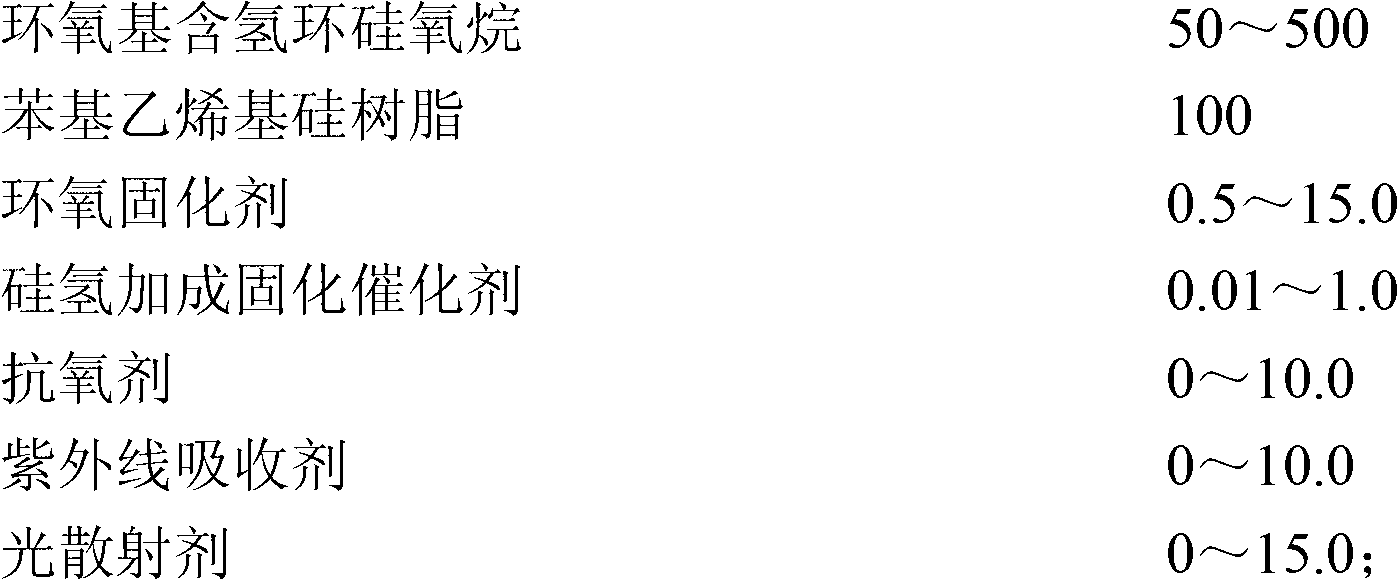

Method used

Image

Examples

Embodiment 1

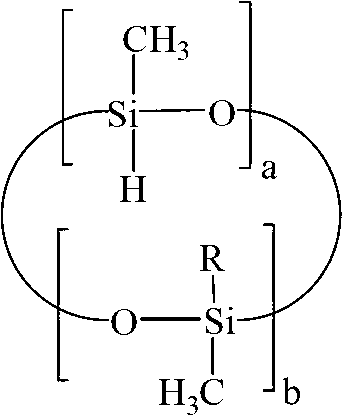

[0061] (1) Preparation of epoxy hydrocyclosiloxane

[0062] Add 1.0mol (240.5g) tetramethylhydrocyclotetrasiloxane (Beijing Huawei Raycus Chemical Co., Ltd.), 2.0mol (248.4g ) 4-vinyl epoxycyclohexane and 400ml of toluene, after argon gas was introduced for 20 minutes, stirred at room temperature, refluxed at 110°C for 1 hour, cooled naturally to room temperature and then heated to 70°C, and 3.1ml was added dropwise after the temperature was constant Concentration is the isopropanol solution of chloroplatinic acid of 0.0125g / ml as catalyst, react 6h after completion of dropwise addition, after the completion of reaction, remove solvent by rotary evaporation, obtain colorless and transparent epoxy group hydrogen-containing cyclosiloxane;

[0063] (2) Preparation of phenyl vinyl silicone resin

[0064] Add 1mol (248.4g) 3-(methacryloyloxy)propyltrimethoxysilane and 0.42g catalyst KI into a round bottom flask equipped with a stirrer, reflux condenser, and thermometer, and stir e...

Embodiment 2

[0068] (1) Preparation of epoxy hydrocyclosiloxane

[0069] Add 1.0 mol (360.8 g) hexamethylhydrocyclohexasiloxane C to a round bottom flask equipped with a stirrer, reflux condenser, thermometer, and nitrogen port 6 h 18 o 6 Si 6 (Kingston Chemical), 5.0 mol (621.0 g) 4-vinylepoxycyclohexane CH 2 =CHC 6 h 9 O and 4900ml of 4-methyl-2-pentanone, after passing argon gas for 30min, stir evenly at room temperature, reflux at 120°C for 0.5h, cool to room temperature naturally, then gradually raise the temperature to 90°C, and slowly add 20.9 The dicyclopentadiene platinum dichloride ethanol solution with a concentration of 0.0125g / ml was used as a catalyst, and reacted for 3 hours after the dropwise addition was completed. After the reaction was completed, the solvent was removed by rotary evaporation to obtain a colorless and transparent epoxy hydrogen-containing ring Silicone;

[0070] (2) Preparation of phenyl vinyl silicone resin

[0071] With 0.1mol (20.4g) allyltriet...

Embodiment 3

[0075] (1) Preparation of epoxy hydrocyclosiloxane

[0076] Add 1.0 mol (480.4 g) octamethylhydrocyclopentasiloxane C to a round bottom flask equipped with a stirrer, reflux condenser, thermometer, and nitrogen port 8 h 24 o 8 Si 8 (Kingston Chemical), 7.0 mol (798.7 g) allyl glycidyl ether CH 2 ═CHCH 2 OCH 2 CHCH 2 O and 1000ml of ethylene glycol dimethyl ether, after passing argon gas for 10 minutes, stir evenly at room temperature, reflux at 85°C for 2h, cool to room temperature naturally, then gradually heat up to 80°C, and slowly add 0.27ml concentration after the temperature is constant The isopropanol solution of chloroplatinic acid of 0.0125g / ml was used as a catalyst, and after the dropwise addition was completed, it was reacted for 12h. After the reaction was completed, the solvent was removed by rotary evaporation to obtain a colorless and transparent epoxy hydrogen-containing cyclosiloxane;

[0077] (2) Preparation of phenyl vinyl silicone resin

[0078] 1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com