Flexible display device and manufacturing method thereof

A technology of a flexible display device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of inability to use plastic substrates, high production temperature, and high substrate requirements, and achieve high picture display quality, Stable drive current and high electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

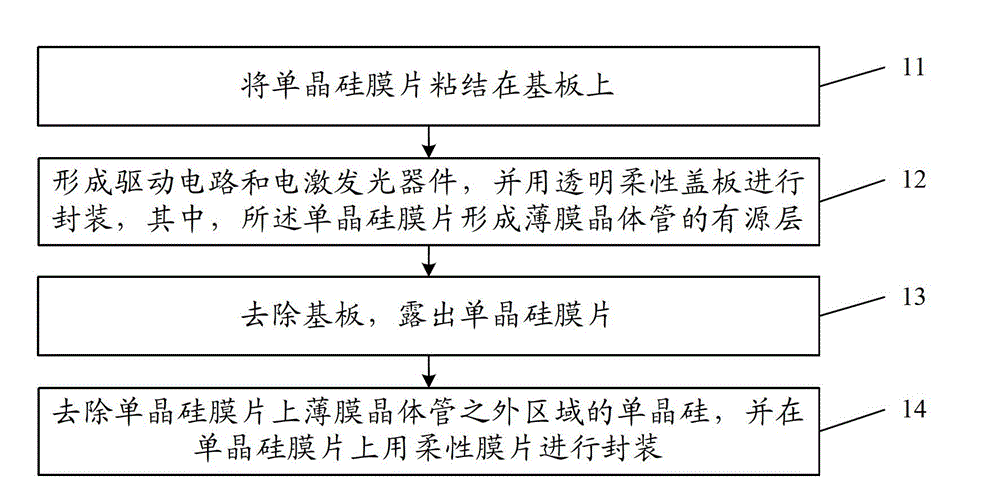

[0087] An embodiment of the present invention provides a method for manufacturing a flexible display device, such as figure 2 As shown, the method includes:

[0088] Step 11, bonding the monocrystalline silicon diaphragm 200 on the substrate 201, such as image 3 , 4 shown;

[0089] Compared with polycrystalline silicon, single crystal silicon has higher electron mobility and very uniform electrical conductivity, and can produce excellent p-type silicon semiconductors and n-type silicon semiconductors. The method of making single crystal silicon is usually to make polycrystalline silicon or amorphous silicon first, and then grow rod-shaped single crystal silicon from the melt by Czochralski method or suspension zone melting method. After the single crystal silicon rod is polished and sliced, it becomes Single crystal silicon wafer, the single crystal silicon diaphragm in this step can be cut from the single crystal silicon wafer according to the size of the display screen ...

specific Embodiment approach

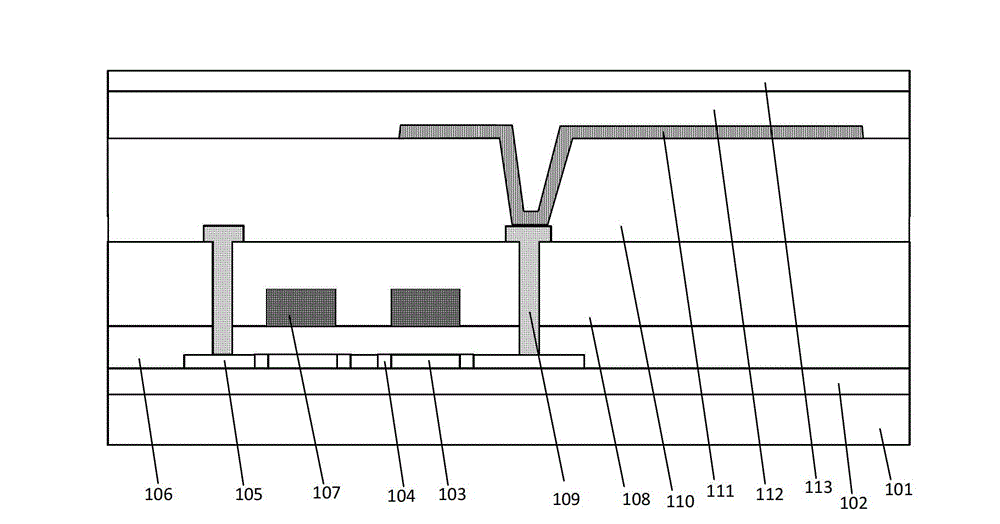

[0093] In this step, a thin film transistor and an electroluminescent device are formed, and an optional specific implementation is as follows:

[0094] 121. If Figure 5 As shown, a gate insulating layer 206 is formed on the single crystal silicon diaphragm 200;

[0095] Optionally, a gate insulating layer 206 is deposited on the monocrystalline silicon diaphragm 200 by plasma chemical vapor deposition (PECVD), and the gate insulating layer 206 can be a silicon nitride SiNx film layer, or a silicon oxide SiOx film layer, or Composite film layer of the two.

[0096] 122. If Figure 6 As shown, a gate electrode layer is formed on the gate insulating layer 206, and a gate electrode 207 is formed by a patterning process;

[0097] In this step, a gate electrode layer is deposited on the gate insulating layer 206 , and the gate electrode 207 can be formed through glue coating, exposure, development, and etching processes.

Embodiment 2

[0128] The present invention also provides a flexible display device, which can be used in any products or components with display functions such as electronic paper, mobile phones, tablet computers, televisions, monitors, notebook computers, digital photo frames, navigators, etc., such as Figure 13 As shown, the device includes:

[0129] flexible diaphragm 214;

[0130] The driving circuit and the electroluminescent device arranged on the flexible diaphragm 214, wherein the active layer of the thin film transistor in the driving circuit is formed by the same single crystal silicon diaphragm, and the thin film transistor includes a first thin film transistor in the display area;

[0131] The transparent flexible cover plate 213 is packaged on the electroluminescence device.

[0132] Compared with the existing technologies, the flexible display device provided by the embodiments of the present invention has the advantages of being bendable, having higher resolution and more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com