Heterojunction bipolar transistor with electrode shielding structure and manufacturing method thereof

A heterojunction bipolar, shielding structure technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of high frequency performance impact, etc., to improve device performance, improve circuit speed, reduce The effect of transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

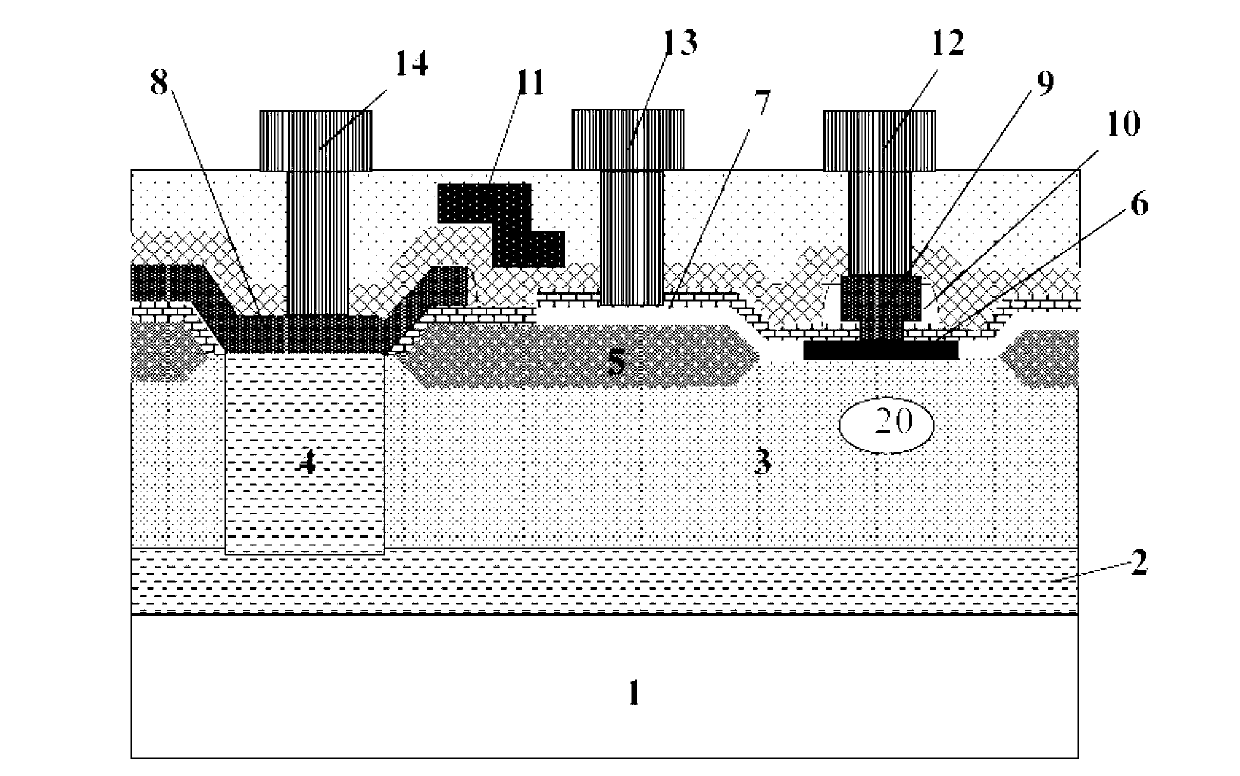

[0026] Preferred embodiment one: as figure 1 As shown, to prepare a bipolar transistor with a common emitter connection method, first prepare a heavily doped P-type substrate silicon wafer 1 . After growing the thin oxide layer, N+ impurities are implanted by photolithography, and then the buried layer 2 is formed. After etching the oxide layer, an N-epitaxial layer 3 is grown.

[0027] Photolithography, implanting N+ impurities to form the lead-out part 4 from the buried layer to the collector. An oxide layer is grown, silicon nitride is deposited, and then the oxide layer and silicon nitride are etched by photolithography to form a field oxygen window, and a thick oxide layer is grown as the field oxide layer 5, and then silicon nitride is removed.

[0028] Lithograph the SIC window, inject N-type impurities, and anneal to form the SIC20; then deposit polysilicon, and then photoetch and etch the polysilicon to form a silicon-germanium epitaxial window, and make a silicon-g...

Embodiment 2

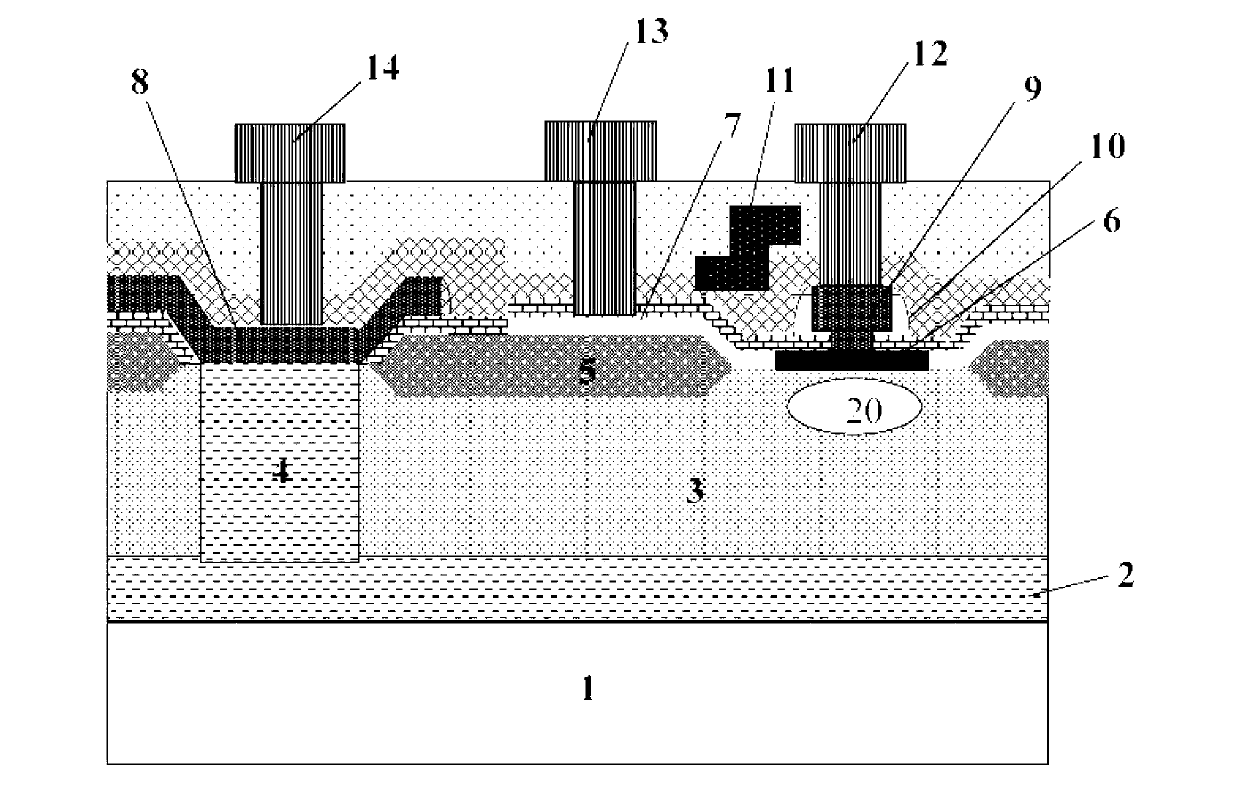

[0032] Preferred embodiment two: as figure 2 As shown, to prepare a bipolar transistor with a common collector connection method, first prepare a heavily doped P-type substrate silicon wafer 1 . After growing the thin oxide layer, N+ impurities are implanted by photolithography, and then the buried layer 2 is formed. After etching the oxide layer, an N-epitaxial layer 3 is grown.

[0033] Photolithography, implanting N+ impurities to form the lead-out part 4 from the buried layer to the collector. An oxide layer is grown, silicon nitride is deposited, and then the oxide layer and silicon nitride are etched by photolithography to form a field oxygen window, and a thick oxide layer is grown as the field oxide layer 5, and then silicon nitride is removed.

[0034] Lithograph the SIC window, inject N-type impurities, and anneal to form the SIC20; then deposit polysilicon, and then photoetch and etch the polysilicon to form a silicon-germanium epitaxial window, and make a silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com