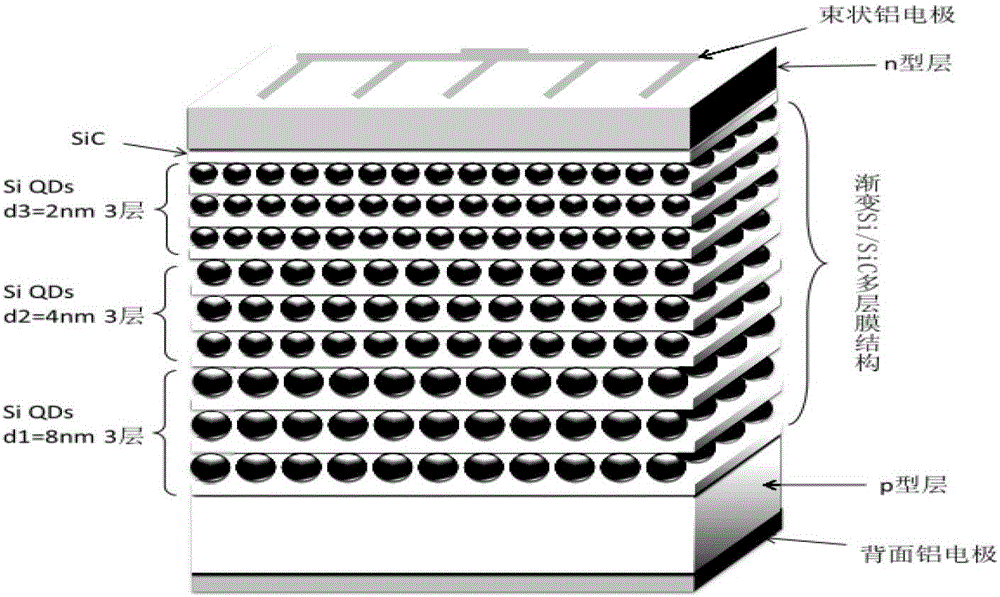

A kind of solar cell and preparation method of bandgap graded silicon quantum dot multilayer film

A technology of silicon quantum dots and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of collection efficiency and conversion efficiency decline, unfavorable transmission channel tunnel operation, increase the number of battery interface layers, etc., to achieve good battery response and energy conversion efficiency, expanding the photoresponse wavelength range, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

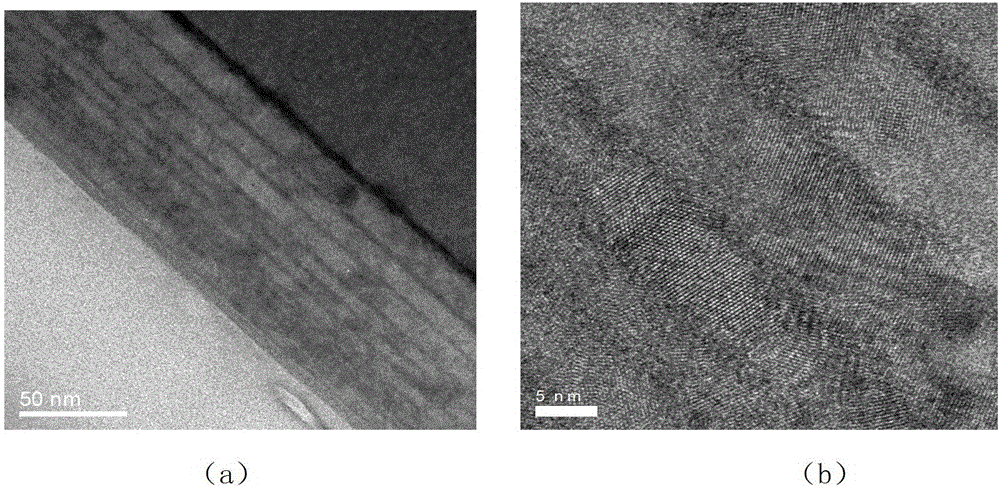

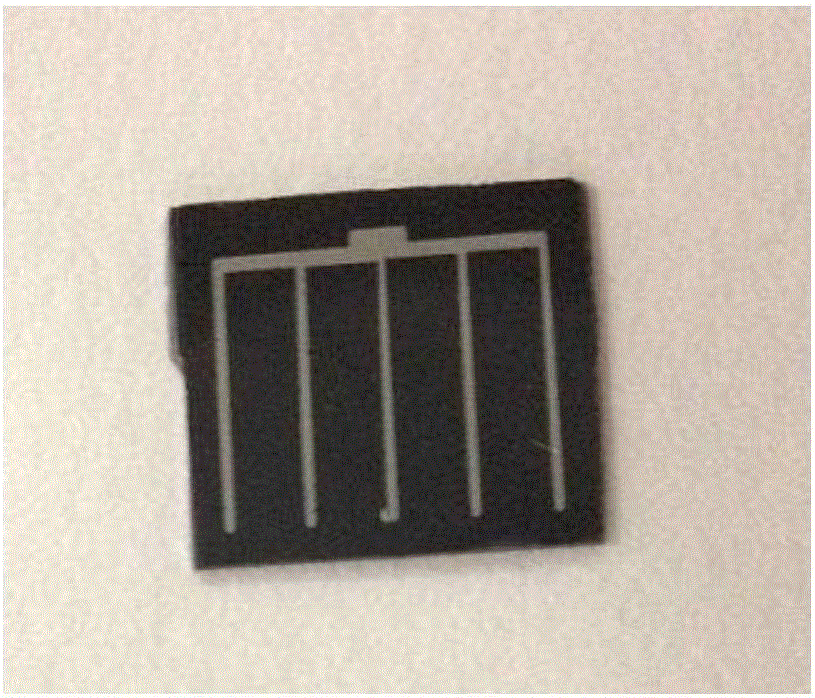

Examples

Embodiment Construction

[0047] The general steps that the present invention prepares:

[0048] The first step: preparing an amorphous silicon / silicon carbide multilayer film structure with a gradual thickness on a p-type silicon substrate;

[0049] 1-1. Growth by chemical vapor deposition or plasma enhanced chemical vapor deposition in a chemical vapor deposition or plasma enhanced chemical vapor deposition system, the substrate temperature is controlled at 250°C, the radio frequency power can be varied between 30W and 50W, and silane is used (SiH 4 ) and methane (CH 4) mixed gas as a reaction gas source, and a hydrogenated amorphous silicon carbide film with a certain thickness is deposited on a p-type single crystal silicon substrate;

[0050] 1-2. After the deposition of the hydrogenated amorphous silicon carbide film is completed, the methane gas source is turned off, and only silane gas is introduced to prepare the hydrogenated amorphous silicon film;

[0051] 1-3. The above two processes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com