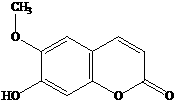

Plant source acaricide microemulsion with 1% scopolactone and preparation method thereof

A technology of scopolide and source acaricide, applied in the field of plant protection, can solve problems such as serious residues, achieve the effects of easy degradation, reduce environmental pollution, and avoid flammable and explosive phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A plant source acaricide scopoletin 1% microemulsion, its composition and mass percentage are 1% scopoletin, 20% N-methylpyrrolidone, 2% agricultural milk 1602, 4% agricultural milk 1601 , 2% ethylene glycol, 3% n-octanol and the balance water.

[0022] The preparation method is:

[0023] (1) According to the stated mass percentage, mix the original drug of scopoletin with the solvent, stir at 40°C to dissolve it completely, then add an emulsifier and stir to form a uniform oil phase;

[0024] (2) According to the mass percentage, mix the antifreeze with water and stir to form a homogeneous water phase;

[0025] (3) Under stirring at 5000~10000 rpm, add the water phase to the oil phase, shear for 30~40 minutes, emulsify it to form an emulsion liquid, and obtain the microemulsion.

Embodiment 2

[0027] A plant source acaricide scopoletin 1% microemulsion, its composition and mass percentage are 1% scopoletin, 5% N-methylpyrrolidone, 5% dimethyl sulfoxide, 4% Termul2507 , 2% agricultural milk 1602, 2% agricultural milk 1601, 2% propylene glycol, 1% glycerin, 1% n-octanol, 1% organic silicon and the balance water. According to the mass percentage, the product preparation is the same as in Example 1.

Embodiment 3

[0029] A plant source acaricide scopoletin 1% microemulsion, its composition and mass percentage are 1% scopoletin, 10% N-methylpyrrolidone, 10% methanol, 10% ethyl acetate, 3 %Termul 2507, 2% agricultural milk 1602, 2% agricultural milk 1601, 3% NP-10, 1% ethylene glycol, 1% propylene glycol, 3% glycerin, 3% n-octanol and the balance water. According to the mass percentage, the product preparation is the same as in Example 1.

[0030] In order to clarify the control effect of this medicament on phytophagous pest mites, a large number of field drug efficacy tests have been carried out with the medicament of the present invention, which proves that the medicament is effective against Tetranychus cinnabarinus, Panonychus citrus, and tea yellow Herbivorous mites such as mites have a good control effect. This agent is diluted 200-400 times, which can effectively control the harm of Tetranychus cinnabarinus in cotton fields. After 7 days of application, the reduction rates of 200-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com