Preparation method of ion induction patch

A technology of ion induction and ion accumulation, applied in the field of medical devices, to achieve the effects of promoting inflammation absorption, improving nutrition, and reducing nerve excitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

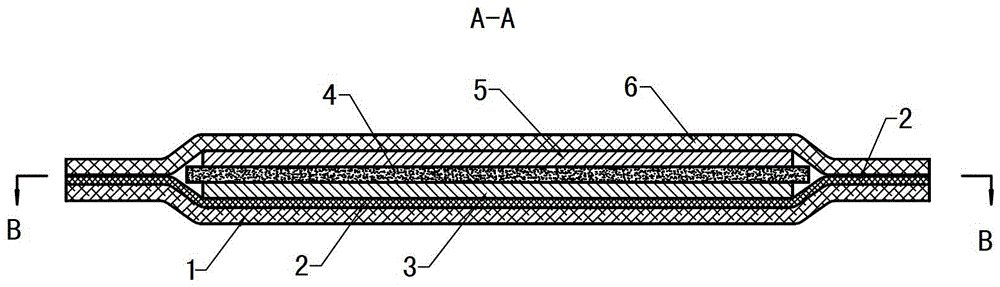

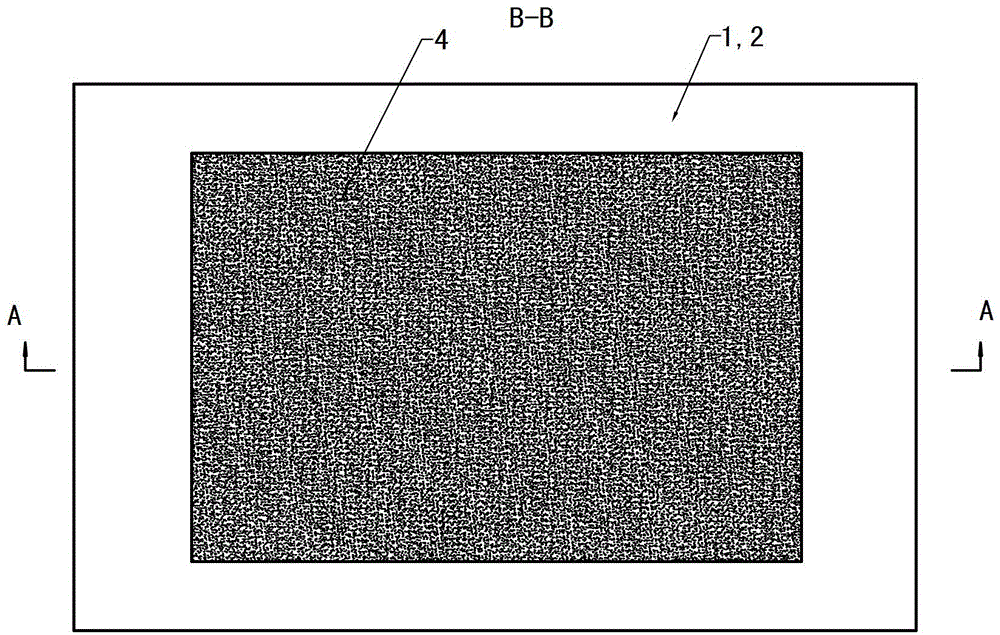

Embodiment 1

[0021] Embodiment 1, Blend and stir 94wt% polytetrafluoroethylene micropowder and 6wt% nanometer far-infrared powder, and then form a film through pressing, drying and other processes. : The molding pressure is 20~30MPa, the sintering temperature is 350~390℃, the holding time is 3~5h, and it is cooled with the furnace; then, it is cut into 145mm*95mm squares; the ion conversion accumulation micro-processing is carried out on the membrane, and the dielectric breakdown is adopted The device is charged, the charging time is 100s, and the charging voltage is 100,000 SEV to form an ion accumulation layer; then place aluminum foil on both sides of the ion accumulation layer, the length and width of the aluminum foil are respectively 90% of the length and width of the ion accumulation layer, and the aluminum foil is obtained Ion stacking layer; then paste one side of the aluminum foil ion stacking layer on the self-adhesive non-woven fabric pasting base layer, and cover the other si...

Embodiment 2

[0022] Embodiment 2, Blend and stir 90wt% of polyimide micropowder and 10wt% of nanometer far-infrared powder, and then form a film through film pressing and drying. : The molding pressure is 20~30MPa, the sintering temperature is 350~390℃, the holding time is 3~5h, and it is cooled with the furnace; then, it is cut into 155mm*105mm squares; the ion conversion stacking micro-treatment is carried out on the membrane, and the dielectric breakdown is adopted The device is charged, the charging time is 120s, and the charging voltage is 80,000 SEV to form an ion accumulation layer; then place silver foil on both sides of the ion accumulation layer, and the length and width of the silver foil are 85% of the length and width of the ion accumulation layer. The silver foil ion accumulation layer is obtained; then, one side of the silver foil ion accumulation layer is pasted on the self-adhesive non-woven fabric pasting base layer, and the other side is covered with a glossy support pa...

Embodiment 3

[0023] Embodiment 3, Blend and stir 86wt% fluorinated polyarylether and 14wt% nano far-infrared powder, and then form a film through lamination, drying and other processes; Process: The forming pressure is 20~30MPa, the sintering temperature is 350~390℃, the holding time is 3~5h, and it is cooled with the furnace; then, it is cut into 145mm*95mm squares; the ion conversion accumulation micro-treatment is carried out on the membrane, and the medium shock is used Wear the device to charge, the charging time is 80s, the charging voltage is 120,000 SEV, and the ion accumulation layer is formed; then aluminum foil is placed on both sides of the ion accumulation layer, and the length and width of the aluminum foil are 95% of the length and width of the ion accumulation layer, respectively. Aluminum foil ion accumulation layer; then paste one side of the aluminum foil ion accumulation layer on the self-adhesive non-woven fabric pasting base layer, and cover the other side with a glo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com