Aliphatic polyester double-layered asymmetric guided tissue regeneration membrane and preparation method thereof

A technology that guides tissue regeneration and aliphatic polyester, applied in medical science, surgery, etc., can solve the problems of complicated post-processing measures, difficult control of membrane pore size, and low spinning efficiency, so as to achieve easy industrialization, The effect of good interlayer bonding and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

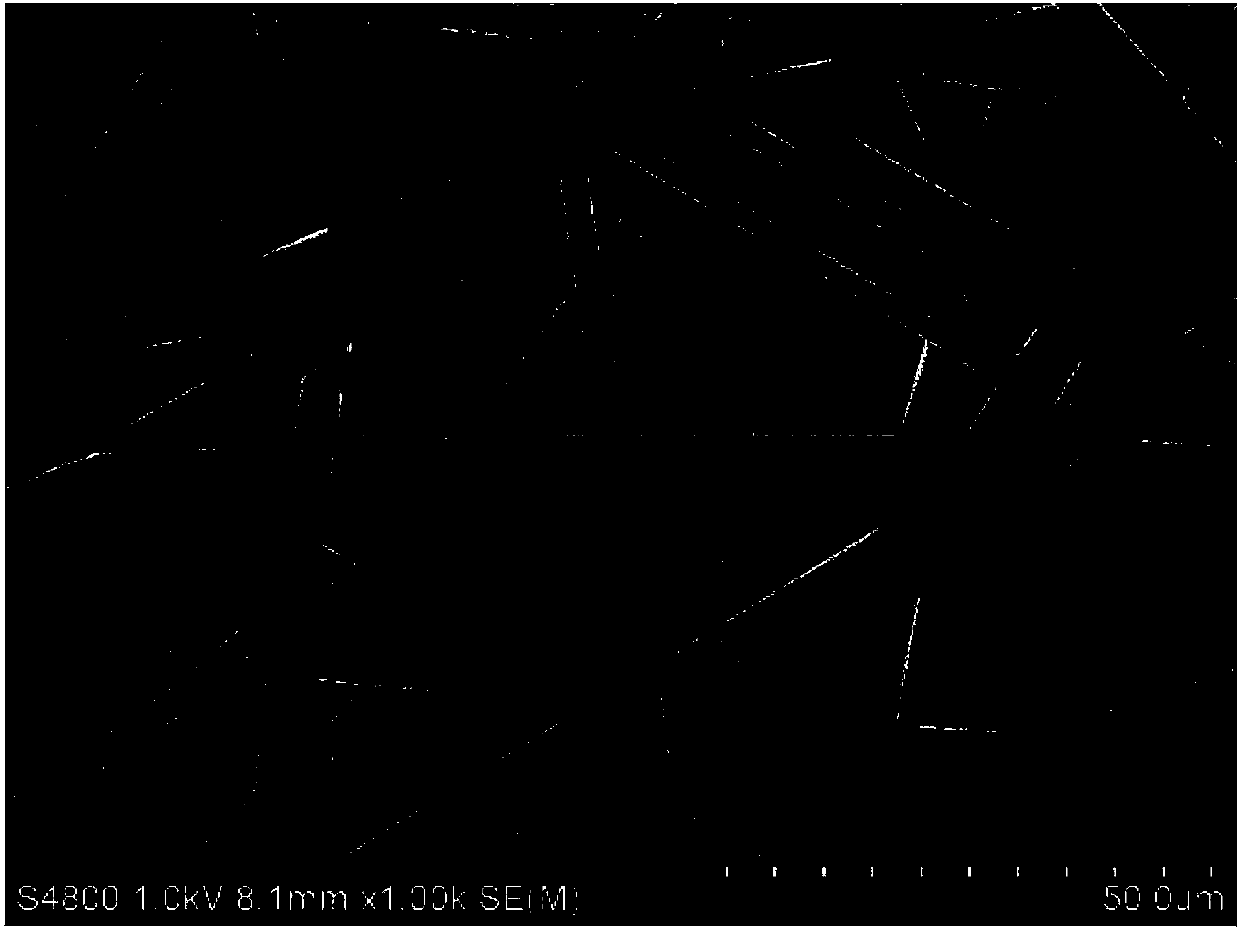

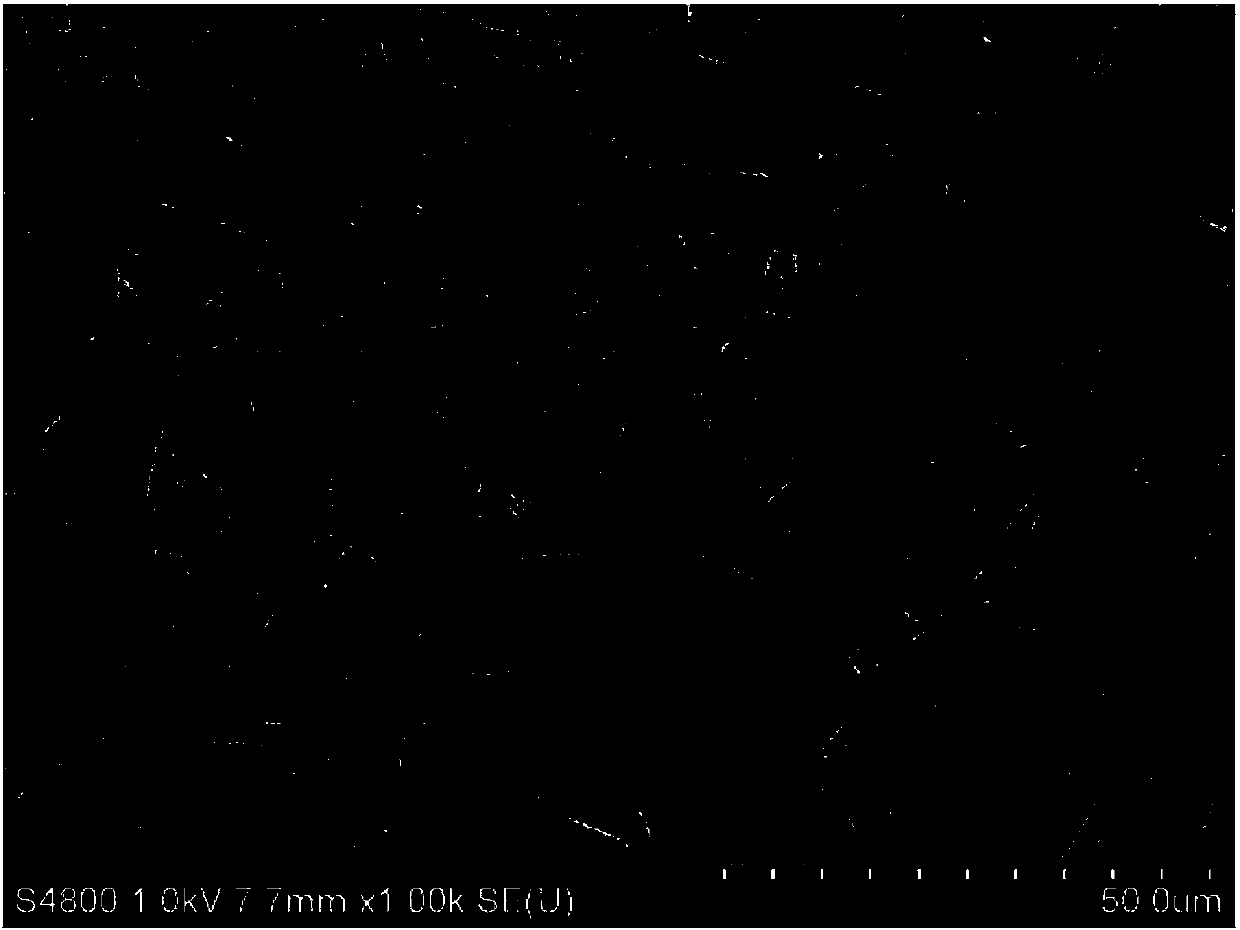

Image

Examples

Embodiment 1

[0024] 1. Dissolve 1.411g of racemic polylactic acid (PDLLA) with a viscosity-average molecular weight of 200,000 in a mixed solvent of 9ml of chloroform and 1ml of N,N-dimethylformamide, stir magnetically at room temperature for 12h, and obtain a concentration of 9%. (w / w) polylactic acid electrospinning solution, stand at room temperature for defoaming; 2.000g polylactic acid glycolic acid copolymer (PLGA, molar ratio 50:50) with a viscosity average molecular weight of 130,000 was dissolved in 8ml tetrahydrofuran and 2mlN , in a mixed solvent of N-dimethylformamide, magnetically stirred at room temperature for 12 hours to obtain a poly(lactic-co-glycolic acid) electrospinning solution with a concentration of 0.2 g / ml, and left to stand at room temperature for defoaming;

[0025] 2. Add the polylactic acid electrospinning solution prepared in step 1 into the liquid reservoir for electrospinning. The initial voltage is 15KV, the receiving distance is 15cm, the liquid output rat...

Embodiment 2

[0032] 1. Dissolve 1.074g of racemic polylactic acid (PDLLA) with a viscosity-average molecular weight of 406,000 in a mixed solvent of 9ml of chloroform and 1ml of N,N-dimethylformamide, stir magnetically at room temperature for 12h, and obtain a concentration of 7%. (w / w) polylactic acid electrospinning solution, left standing at room temperature for defoaming;

[0033] 2. Take 5ml of the polylactic acid electrospinning solution prepared in step 1 and add it to the liquid reservoir for electrospinning. The spinning conditions are: voltage 15KV, receiving distance 20cm, liquid output rate 7ml / h, and the receiving device is tinfoil attached to the surface A rotating stainless steel disk (diameter 100mm), the disk rotating speed is 300rpm, and the obtained diameter is 100mm, and the polylactic acid electrospun membrane that thickness is 0.2mm;

[0034] 3. Place the polylactic acid electrospun membrane obtained in step 2 between two flat plates with fine patterns on the inner su...

Embodiment 3

[0040] 1. Dissolve 1.074g of racemic polylactic acid (PDLLA) with a viscosity-average molecular weight of 406,000 in a mixed solvent of 9ml of chloroform and 1ml of N,N-dimethylformamide, stir magnetically at room temperature for 12h, and obtain a concentration of 7%. (w / w) polylactic acid electrospinning solution, let it stand at room temperature for defoaming; dissolve 1.411g of racemic polylactic acid (PDLLA) with a viscosity average molecular weight of 200,000 in 9ml of chloroform and 1ml of N,N-dimethylformaldehyde In the mixed solvent of amide, stir magnetically at room temperature for 12 hours to obtain a polylactic acid electrospinning solution with a concentration of 9% (w / w), and let it stand at room temperature for defoaming;

[0041] 2. Add the polylactic acid electrospinning solution with a concentration of 7% (w / w) prepared in step 1 into the liquid reservoir for electrospinning. The initial voltage is 15KV, the receiving distance is 20cm, and the liquid output ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com