Preparation method of Ti<3+>-doped TiO2 composite graphene photocatalyst

A composite graphene and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of inability to reduce hydroxyl and carboxyl groups, low alcohol reducibility, environmental pollution, etc., to achieve Improved transfer efficiency, simplified equipment, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

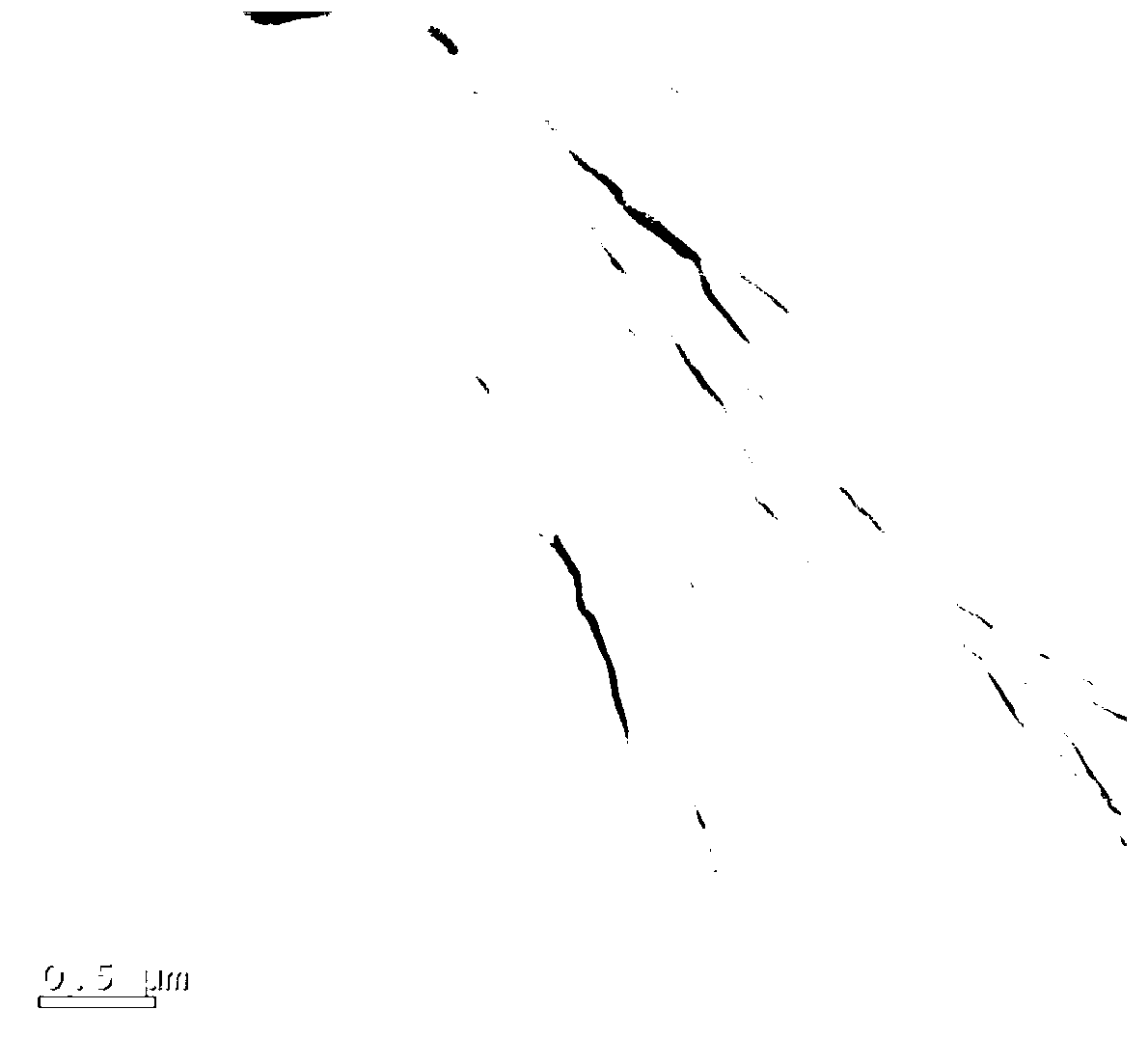

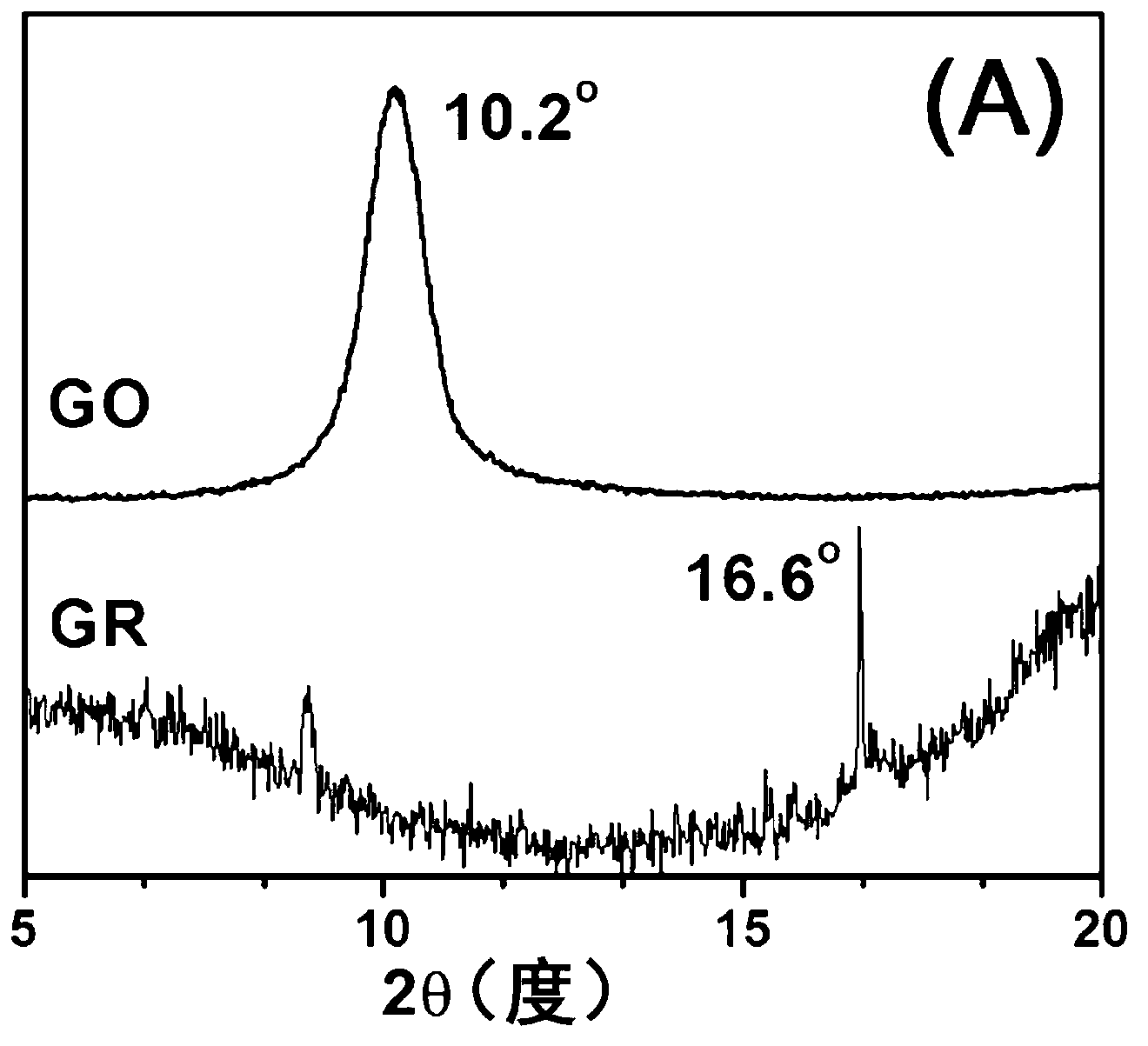

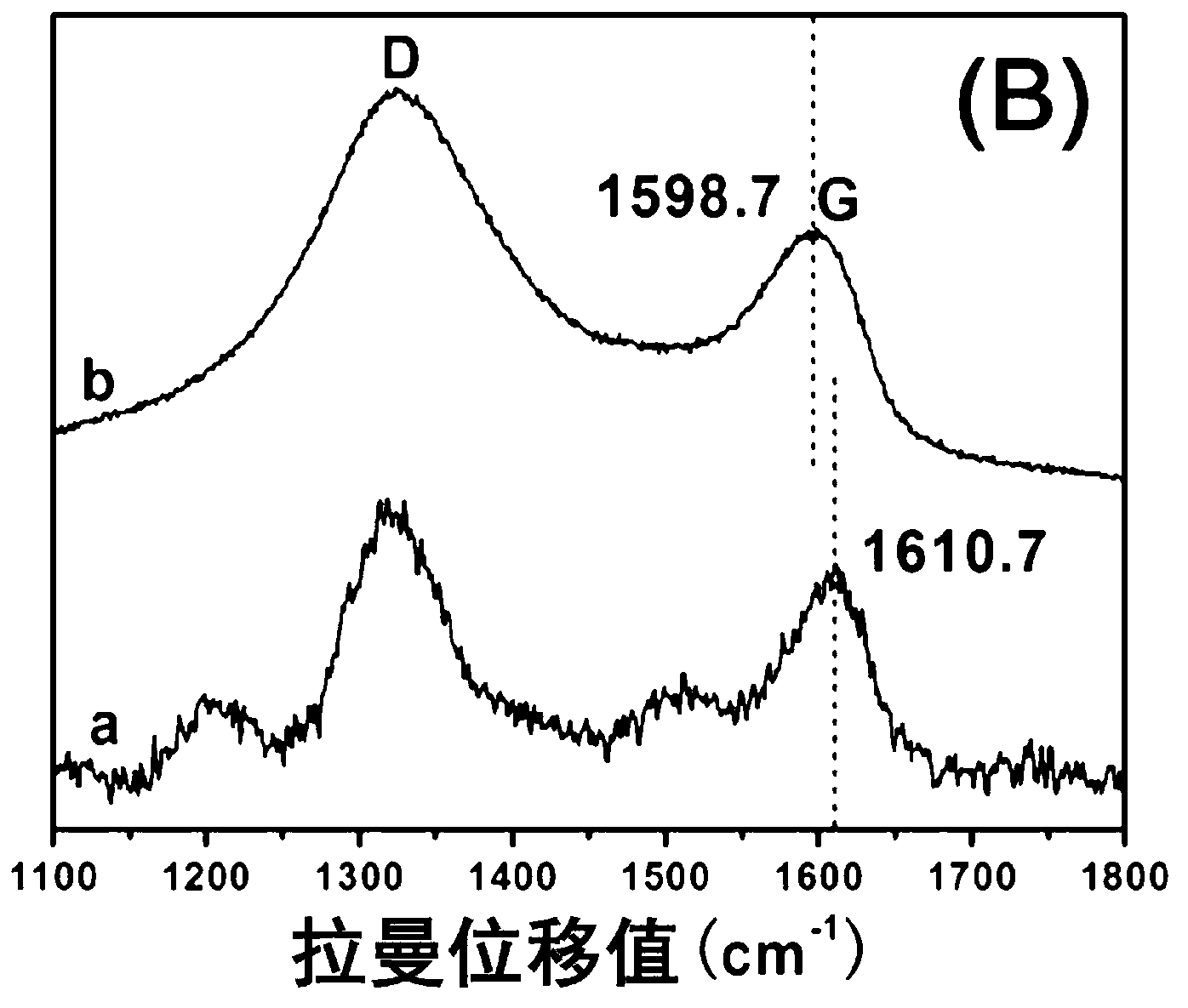

[0031] Preparation of Graphene Oxide (GO)

[0032] The "Hummer" method was used to prepare GO, and the specific method was as follows: 3 g of graphite was dispersed in 12 ml of concentrated sulfuric acid containing 2.5 g of potassium persulfate and 2.5 g of phosphorus pentoxide, stirred at 80 °C for 4.5 h, then cooled to room temperature and placed at room temperature for 12 h . The resulting mixture was filtered, washed and naturally dried for 12 h. The pretreated graphite was added to 120ml of concentrated sulfuric acid, and 15g of potassium permanganate was added while stirring while keeping the temperature below 20°C, and stirred at 35°C for 2h. The mixture was diluted with 250 mL of deionized water, and the temperature was kept below 50°C in an ice-water bath. After stirring for 2 h, 0.7 L of deionized water was added, followed by the slow addition of 20 ml of 30% hydrogen peroxide. The mixed solution was bright yellow and bubbling. Stand still, remove the supernatant...

Embodiment 2

[0034] Preparation of Graphene (GR) Composite P25 Photocatalyst

[0035] The graduated cylinder measures 0.02ml of graphene oxide (GO) with a concentration of 2.1mg / ml prepared in Example 1, and disperses it in 40ml of ultrapure water. After ultrasonic dispersion for 1h, add 0.5g of P25, stir magnetically for 1h, and then After ultrasonication for 1h, drying at 100°C, and vacuum activation at 300°C for 3h, a P25 supported graphene (GR) catalyst was obtained, marked as: V-P25-0.02GR.

Embodiment 3

[0037] The graduated cylinder measures 0.05ml of graphene oxide (GO) with a concentration of 2.1mg / ml prepared in Example 1, and disperses it in 40ml of ultrapure water. After ultrasonic dispersion for 1h, add 0.5g of P25, stir magnetically for 1h, and then After ultrasonication for 1h, drying at 100°C, and vacuum activation at 300°C for 3h, a P25 supported graphene (GR) catalyst was obtained, marked as: V-P25-0.05GR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com