Method for preparing zirconium phosphate layer column material by guide assembly technology

A technology of zirconium phosphate layer and assembly technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve the effect of maintaining regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

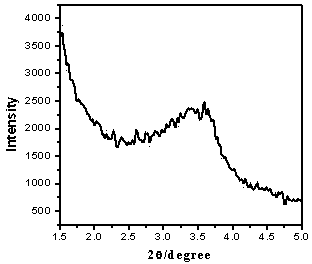

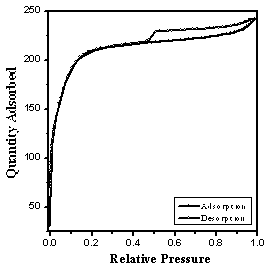

Image

Examples

Embodiment 1

[0020] Embodiment one: In a dry 500 mL beaker, uniformly disperse 0.06 g of α-ZrP powder to 300 mL with a concentration of 0.4 mmol.L -1 In the alcohol-water dispersion of cetylamine, the solid-to-liquid ratio is 1:5 g / L, the molar ratio of organic amine: α-zirconium phosphate is 0.6:1, the volume ratio of alcohol to water is 1:1, and the water bath is 50°C Under magnetic stirring for 24 hours, after filtration and drying, layered organic zirconium phosphate was obtained. 0.1 mol.L at a concentration of 1.60 mL -1 Dodecyl dimethyl benzyl ammonium chloride aqueous solution and 0.45mL tetraethyl orthosilicate to form a microemulsion, and the organic zirconium phosphate is dispersed in the microemulsion, wherein dodecyl dimethyl benzyl ammonium chloride The molar ratio of zirconium organophosphate to zirconium organophosphate is 0.8:1, the molar ratio of ethyl orthosilicate to zirconium organophosphate is 10:1, the solid-liquid ratio of zirconium organophosphate and microemuls...

Embodiment 2

[0023] Embodiment two: In a dry 500 mL beaker, uniformly disperse 0.06 g of α-ZrP powder to 300 mL with a concentration of 0.4 mmol.L -1 In the alcohol-water dispersion of cetylamine, the solid-to-liquid ratio is 1:5 g / L, the molar ratio of organic amine: α-zirconium phosphate is 0.6:1, the volume ratio of alcohol to water is 1:1, and the water bath is 50°C Under magnetic stirring for 24 hours, after filtration and drying, layered organic zirconium phosphate was obtained. 0.1 mol.L at a concentration of 1.60 mL -1 Dodecyl dimethyl benzyl ammonium chloride aqueous solution and 0.18mL tetraethyl orthosilicate to form a microemulsion, the organic zirconium phosphate is dispersed in the microemulsion, wherein dodecyl dimethyl benzyl ammonium chloride The molar ratio of zirconium organophosphate to zirconium organophosphate is 0.8:1, the molar ratio of ethyl orthosilicate to zirconium organophosphate is 4:1, the solid-liquid ratio of zirconium organophosphate and microemulsion i...

Embodiment 3

[0024] Embodiment three: In a dry 500 mL beaker, uniformly disperse 0.06 g of α-ZrP powder to 300 mL with a concentration of 0.4 mmol.L -1 In the alcohol-water dispersion of cetylamine, the solid-to-liquid ratio is 1:5 g / L, the molar ratio of organic amine: α-zirconium phosphate is 0.6:1, the volume ratio of alcohol to water is 1:1, and the water bath is 50°C Under magnetic stirring for 24 hours, after filtration and drying, layered organic zirconium phosphate was obtained. 0.1 mol.L at a concentration of 1.60 mL -1 Tetradecyl dimethyl benzyl ammonium chloride aqueous solution and 0.45mL orthosilicate ethyl ester to make a microemulsion, the organic zirconium phosphate is dispersed in the microemulsion, wherein tetradecyl dimethyl benzyl ammonium chloride The molar ratio of zirconium organophosphate to zirconium organophosphate is 0.8:1, the molar ratio of ethyl orthosilicate to zirconium organophosphate is 10:1, the solid-liquid ratio of zirconium organophosphate and micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com