A kind of nano flake spherical anatase titanium dioxide and preparation method thereof

A nano-flaky, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of damage to the spherical structure and increase the cost, and achieve the effect of improved photocatalytic performance, excellent performance and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

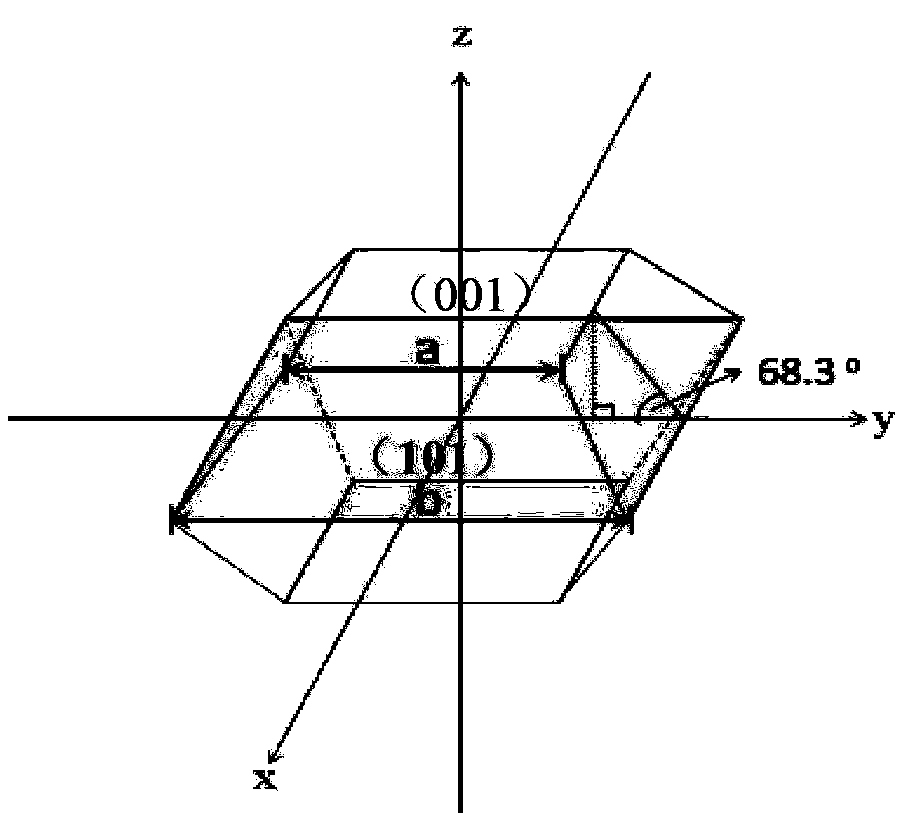

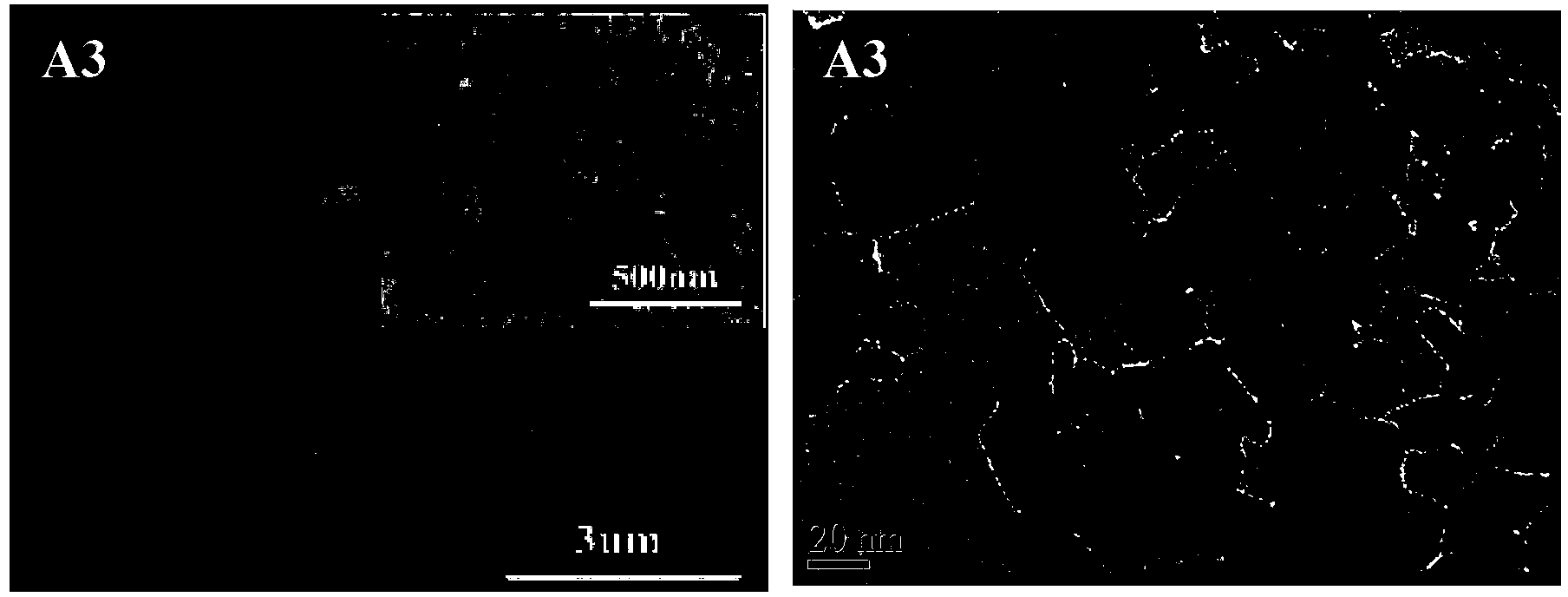

[0032] Under magnetic stirring, 0.38g of water and 0.2g of fluorosilicic acid (H 2 SiF 6 ) mixed solution slowly drop into 4.98g butyl titanate (TBOT), the obtained molar ratio is 1TBOT:0.1H 2 SiF 6 : 1.5H 2 O, after stirring for 30 minutes, move it into the polytetrafluoroethylene lining of a 50mL stainless steel kettle, put it into a 180°C oven for crystallization for 72 hours, and then cool it down to room temperature naturally. The samples were washed with ethanol and deionized water, filtered with suction, and dried in an oven at 50°C for 12 hours. The obtained sample is nano-flaky spherical anatase titanium dioxide, and the sample is denoted as A3, and then the sample A3 is calcined at 600° C. for 2 hours. The average diameter of sample A3 after crystallization is 4.5um ( image 3 Left), the surface of the spheroid is composed of nanosheet-like ten-sided bipyramids with truncated double tops ( image 3 Right), and by calculation, the exposure rate of the high-energ...

example 2-4

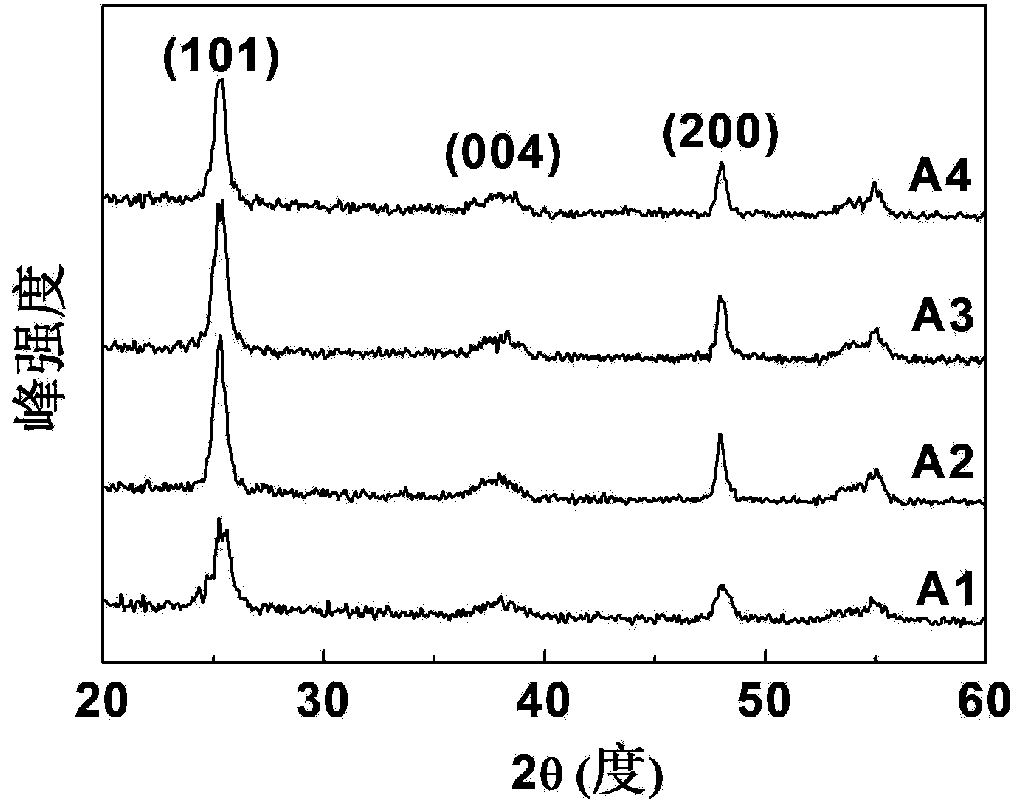

[0034] The experiment was carried out with the same method as in Example 1, changing the crystallization temperature and time to 24h, 48h, and 96h, and the obtained samples were nano-flaky spherical anatase titanium dioxide, and the samples were respectively marked as A1, A2, and A4. Characterization by X-ray diffraction shows that the crystallinity increases significantly with the increase of crystallization time, but the crystallinity of sample A4 decreases slightly when the crystallization time increases to 96h ( figure 2 ).

example 5-6

[0036] The experiment was carried out with the same method as Example 1, and the crystallization temperature was changed to 160 and 200° C., and the obtained samples were nano-flaky spherical anatase titanium dioxide, and the samples were respectively marked as A5 and A6. Characterization by X-ray diffraction shows that with the increase of temperature, the crystallinity is slightly enhanced, but not obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com