Method of semi-continuously producing particle-size-controllable ADC (azodicarbonamide) foaming agent

A semi-continuous technology for ADC foaming agent, applied in the field of semi-continuous production of ADC foaming agent with controllable particle size, to achieve the effect of reducing post-processing procedures, improving product quality stability, and improving use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

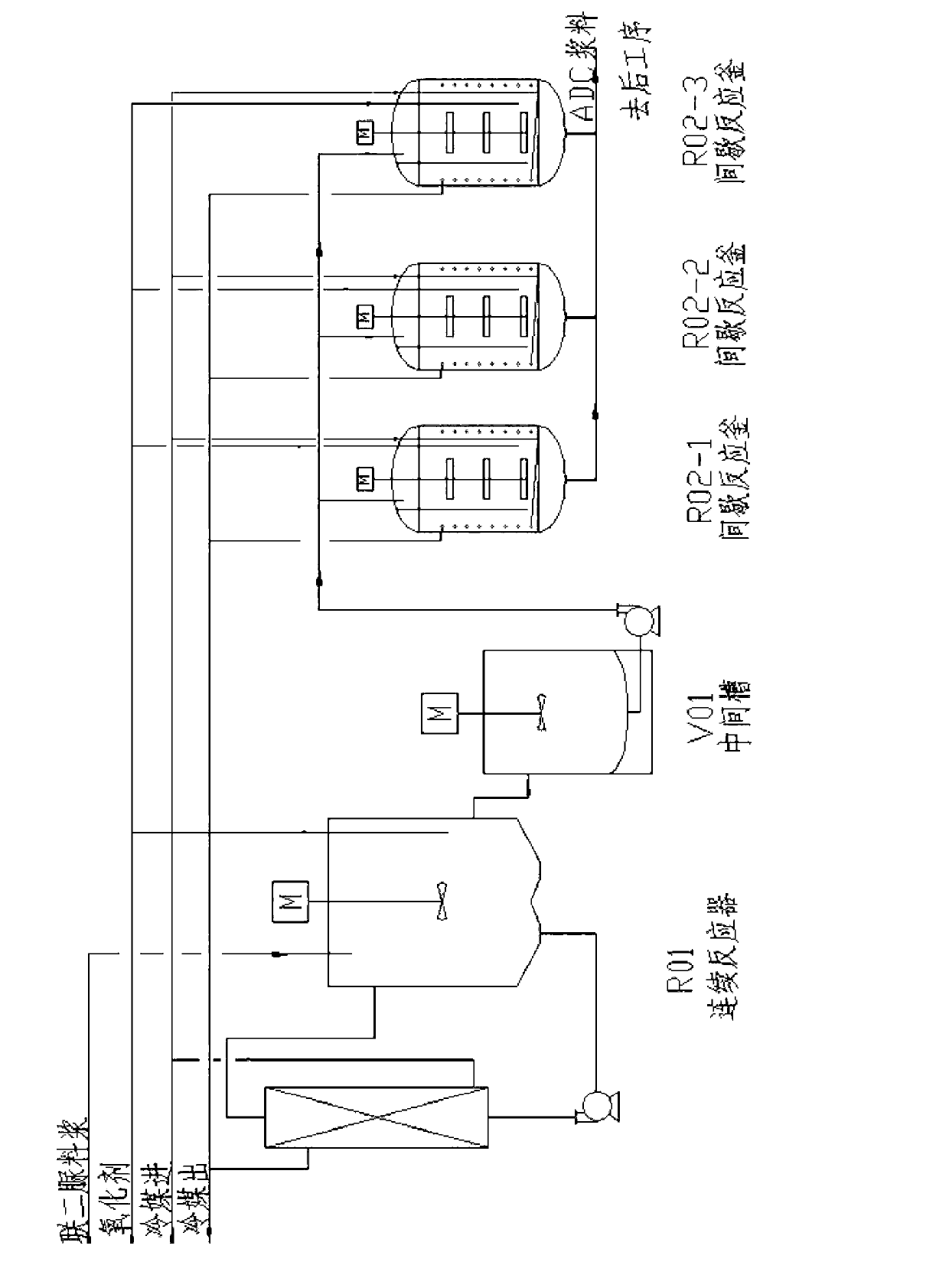

Method used

Image

Examples

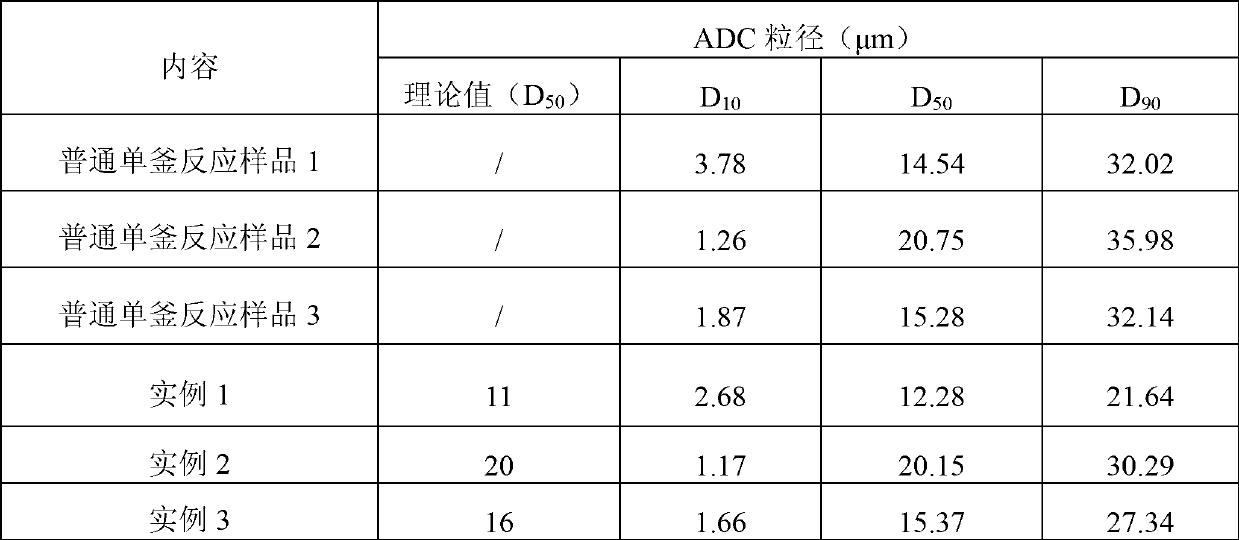

Embodiment 1

[0026] The continuous reactor volume R01 is 300L, and the batch reactor R02 is 10L. Biurea is formulated into a slurry with a solid content of 30%. First consider oxidation with hydrogen peroxide, and then add hydrochloric acid, sodium bromide, and an iron-based catalyst to make the content of hydrochloric acid in the slurry 8%, and the content of sodium bromide 1%. The content of iron-based catalyst is 0.6%, and the total amount of biurea slurry after preparation is 400L. Then feed into the continuous reactor R01, start stirring, control the stirring speed at 20 rpm (frequency 15hz), stop feeding when the slurry level is just ready for forced circulation, open the hydrogen peroxide feed valve, and start the continuous reaction Add 40% industrial hydrogen peroxide to the reactor at a rate of 1L / h to react, turn on the refrigerant, control the material temperature of the continuous reactor to 50°C, and take a sample at the material outlet after reacting for 3 to 5 hours, and th...

Embodiment 2

[0029] The continuous reactor volume R01 is 300L, and the batch reactor R02 is 10L. Biurea is formulated into a slurry with a solid content of 30%, oxidized with hydrogen peroxide, and then adding hydrochloric acid, sodium bromide, and an iron-based catalyst to make the slurry have a hydrochloric acid content of 8%, a sodium bromide content of 1%, and an iron-based catalyst. The catalyst content is 0.6%, and the biurea slurry after preparation is 400L in total. Then feed the material to the continuous reactor R01, start stirring, control the stirring speed at 55 rpm (frequency 40hz), and when the slurry level is just ready for forced circulation, stop feeding, open the hydrogen peroxide feed valve, and feed to the continuous reactor R01. Add 40% industrial hydrogen peroxide to the reactor at a rate of 1L / h for reaction, turn on the refrigerant, control the temperature of the material in the continuous reactor to 50°C, and take a sample at the material outlet after reacting for...

Embodiment 3

[0032] The continuous reactor volume R01 is 300L, and the batch reactor R02 is 10L. The biurea is formulated into a slurry with a solid content of 30%, which is oxidized by chlorine gas. The content of sodium bromide in the slurry is 0.8% of the biurea content, and the total amount of the biurea slurry after preparation is 400L. Then feed the continuous reactor R01, start stirring, control the stirring speed to 42 rpm (frequency is 30hz), and when the slurry liquid level is just able to carry out forced circulation, stop feeding, open the chlorine gas feed valve, and start liquid Phase feed, add chlorine gas to the continuous reactor at a rate of 70L / h to react, turn on the refrigerant, control the material temperature of the continuous reactor to 35°C, and take a sample at the material outlet after reacting for 3 to 5 hours. When the amount reaches about 30%, open the biurea feed valve, feed the material into the continuous reactor R01 according to the speed of 10L / h, and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com