Salt-resistant drilling fluid with super-high density, preparation method and application thereof

An ultra-high density, drilling fluid technology, applied in the field of oil drilling, can solve the problems of increased drilling fluid cost, less mineral resources, unfavorable promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

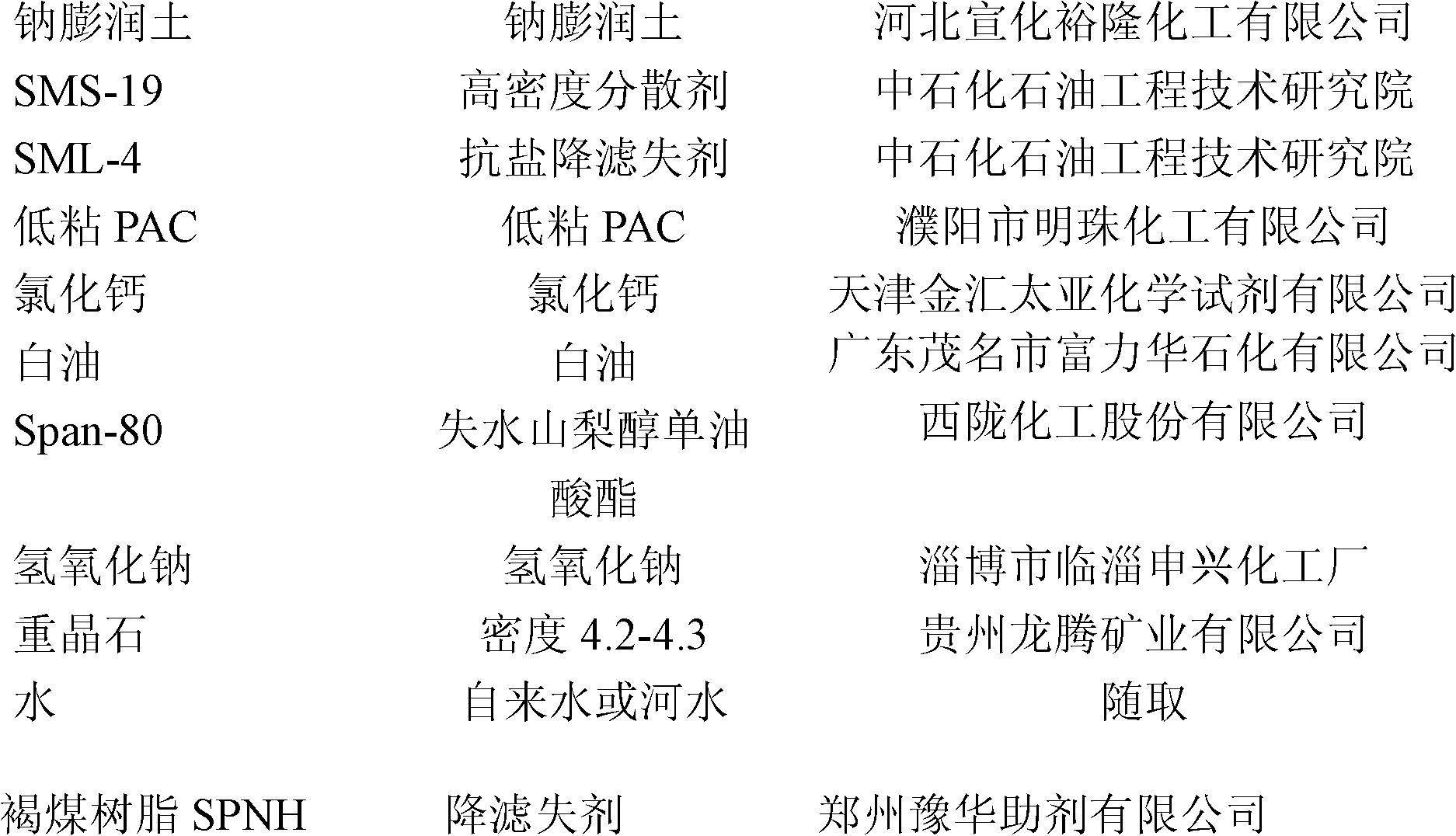

[0049] Preparation of dispersant:

[0050] 18 parts of woody lignin, 10 parts of p-cresol, 8 parts of sodium sulfite, 3 parts of formaldehyde, 1 part of p-toluenesulfonic acid, 100 parts of water, mixed evenly and reacted at 160-170 °C for 8 hours, and dried to obtain the dispersant SMS- 19A.

[0051] 20 parts of herbal lignin, 10 parts of phenol, 8 parts of sodium sulfite, 2 parts of formaldehyde, 1.2 parts of p-toluenesulfonic acid, 100 parts of water, mix well, react at 160-170°C for 8 hours, and dry to prepare dispersant SMS-19B.

[0052] 25 parts of woody lignin, 8 parts of phenol, 8 parts of sodium sulfite, 4 parts of acetaldehyde, 1 part of sulfamic acid, 100 parts of water, mixed evenly, reacted at 170-180°C for 6 hours, and dried to prepare the dispersant SMS-19C .

[0053] Preparation of fluid loss reducer:

[0054] 28 parts of sulfonated lignite, 2 parts of formaldehyde, 11 parts of sulfonate polymer, and 100 parts of water were mixed evenly and reacted at 200°C ...

Embodiment 1

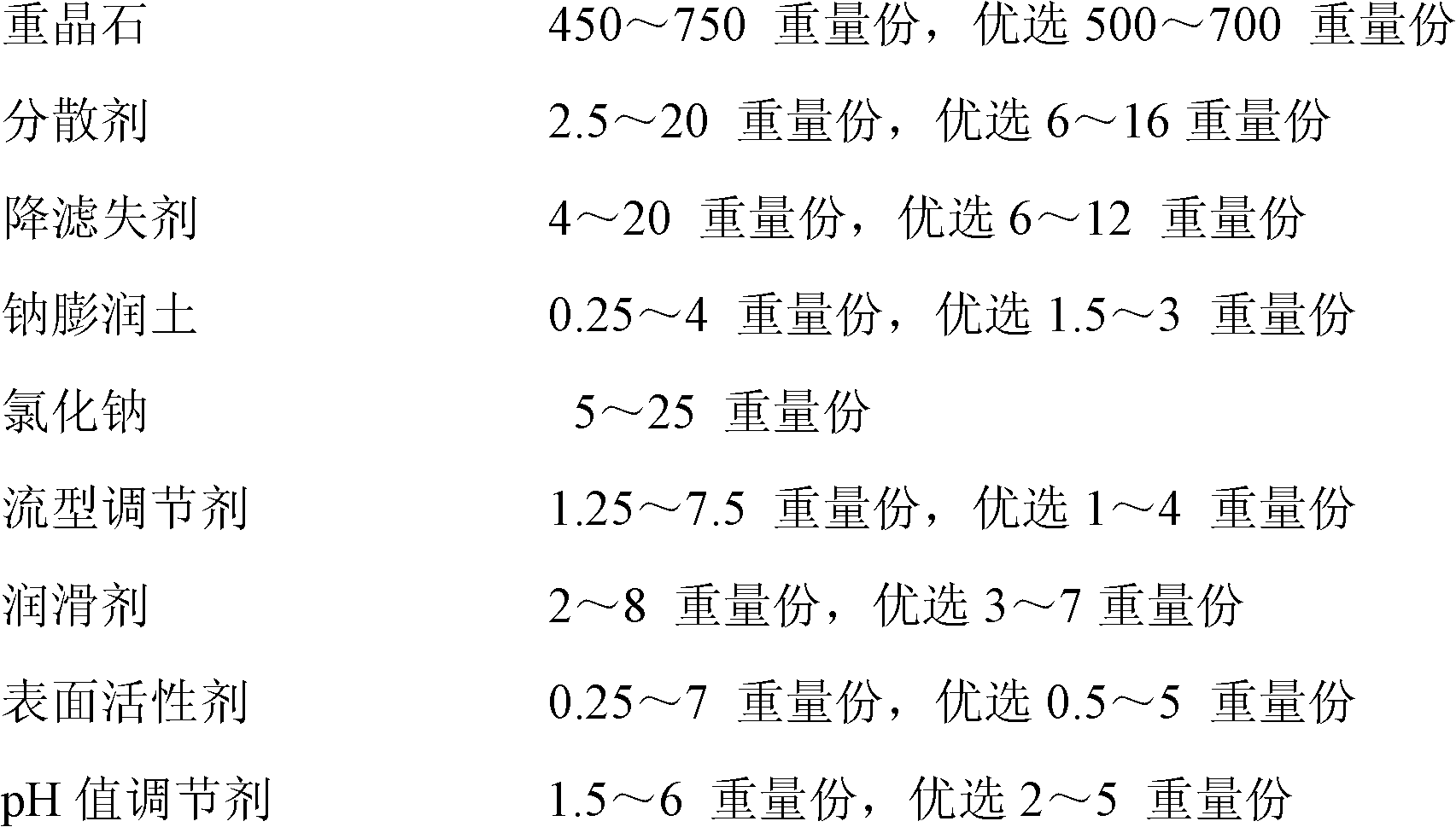

[0058] The density is 2.75g / cm 3 The distribution ratio of salt-resistant ultra-high-density drilling fluid components is as follows based on 100 parts by weight of water:

[0059]

[0060] Prepare sodium bentonite slurry according to the above component ratio, after aging for 24 hours, add dispersant SMS-19, anti-salt fluid loss reducer SML-4, flow regulator low-viscosity PAC, lubricant white oil, surface Active agent Span-80, sodium chloride, and pH regulator sodium hydroxide were stirred until they were evenly dissolved, and barite powder was added under stirring, and the performance of the drilling fluid before aging was tested after stirring at high speed for 20 minutes. The ultra-high-density drilling fluid prepared according to the above method was placed in a high-temperature aging tank, rolled at 120°C for 16 hours, and cooled to 55°C to test the performance of the drilling fluid after aging. The performance of the ultra-high density drilling fluid with the above ...

Embodiment 2

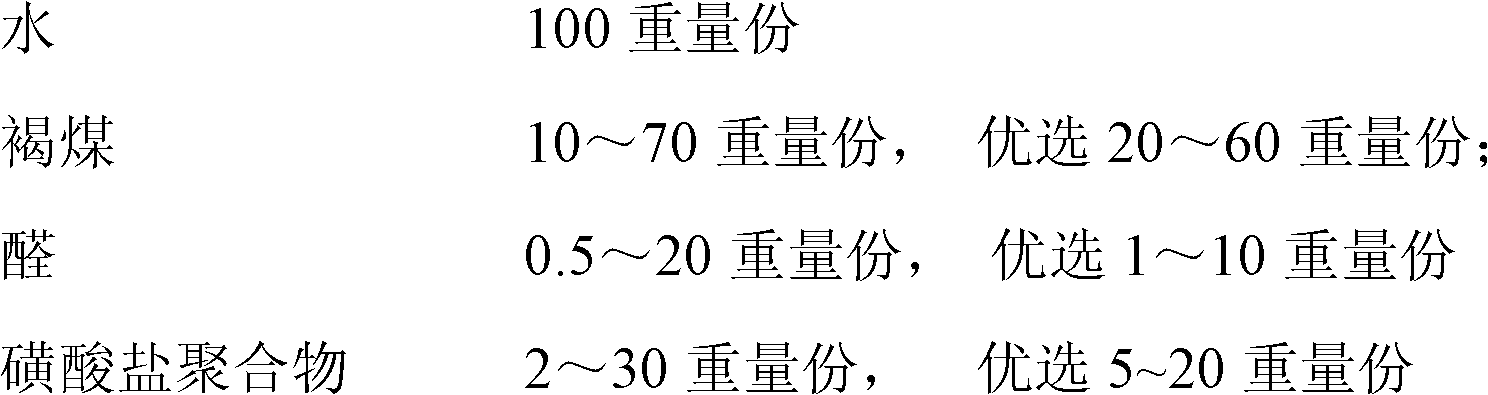

[0065] The density is 2.88g / cm 3 The distribution ratio of salt-resistant ultra-high-density drilling fluid components is as follows based on 100 parts by weight of water:

[0066]

[0067] Prepare sodium bentonite slurry according to the above component ratio, after aging for 24 hours, add dispersant SMS-19, anti-salt fluid loss reducer SML-4, flow regulator low-viscosity PAC, lubricant white oil, surface Active agent Span-80, sodium chloride, and pH regulator sodium hydroxide were stirred until they were evenly dissolved, and barite powder was added under stirring, and the performance of the drilling fluid before aging was tested after stirring at high speed for 20 minutes. The ultra-high-density drilling fluid prepared according to the above method was placed in a high-temperature aging tank, rolled at 120°C for 16 hours, and cooled to 55°C to test the performance of the drilling fluid after aging. The performance of the ultra-high density drilling fluid with the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com