Proteolysis micro-fluidic chip based on silica gel oxidized graphene composite membrane and fabrication method of proteolysis micro-fluidic chip

A microfluidic chip and graphene composite technology, which is applied in the direction of enzyme production/bioreactor, can solve the problems of affecting the effect of enzymatic hydrolysis and easy loss, and achieve the effect of simple process, easy production and saving enzymatic hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

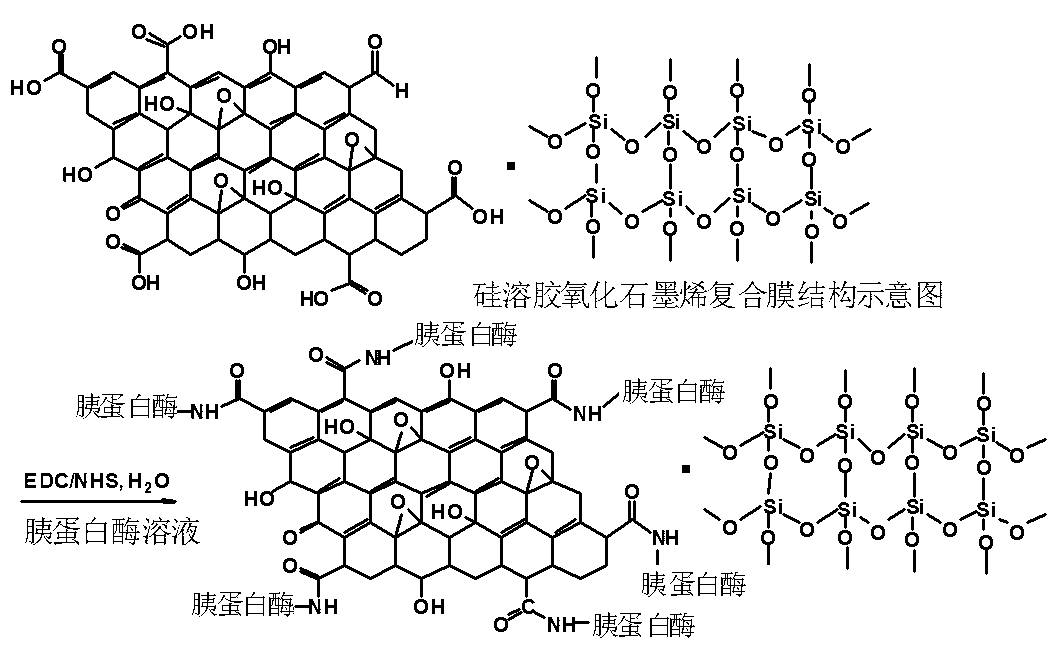

[0045] Example 1. Proteolysis microfluidic chip based on silica gel graphene oxide composite membrane immobilized with trypsin

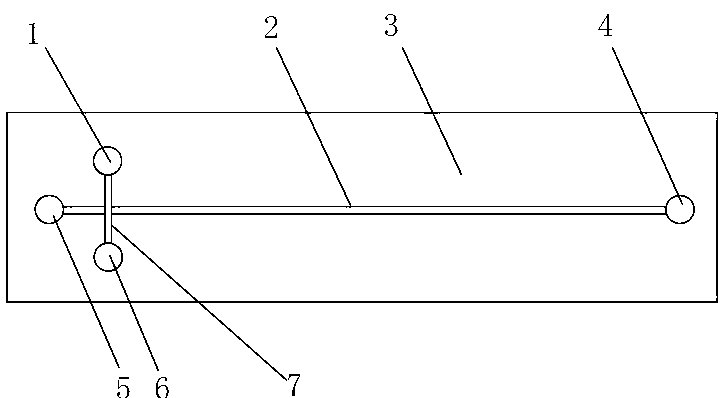

[0046] Using computer-aided design software to design the chip structure, the typical design is as follows: figure 1 As shown, it consists of single cross microfluidic channels 2 and 7, solution connection holes 1, 5, 6 and enzymatic solution collection hole 4, and is printed on a transparent film as a mask by using a high-resolution (such as 3600 dpi) laser phototypesetting system. Membrane, the microchannel part is a black line with a width of 40 microns, and the other part is transparent. A layer of positive photoresist ( Shipley S1813 photoresist, Shipley, Marlborough, MA, USA), spin-coating conditions were 3000 rpm for 60 seconds. Then bake at 110 ℃ for 60 seconds to improve the adhesion of the photoresist and remove the residual solvent (baking before exposure), and then cover the mask (including the designed microfluidic structure), using K...

Embodiment 2

[0052] Example 2, proteolysis microfluidic chip based on immobilized protease silica gel graphene oxide composite membrane

[0053] In addition, using the method of the present invention, a proteolysis microfluidic chip based on a silica gel graphene oxide composite membrane immobilized with protease is also prepared. Except for the enzyme immobilization step, others are the same as in Example 1. The specific method is: inject 2 mg / ml 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1 mg / ml into the modified channel of the silica gel graphene oxide composite membrane. A mixed solution of N-hydroxysuccinimide in 1 ml was used to activate the carboxyl groups of graphene oxide on the channel surface, followed by injection of 50 mmol / L phosphate buffer solution (pH 7.4) containing 2 mg / ml protease at room temperature The reaction was carried out for 4 hours, and the protease was immobilized through covalent bonds to obtain a proteolysis microfluidic chip with a sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com