Preparation method of coal-based composite chelating agent

A chelating agent, coal-based technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high cost, unsatisfactory effect, limited source of matrix, etc., and achieve good mechanical properties, excellent chelating performance, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

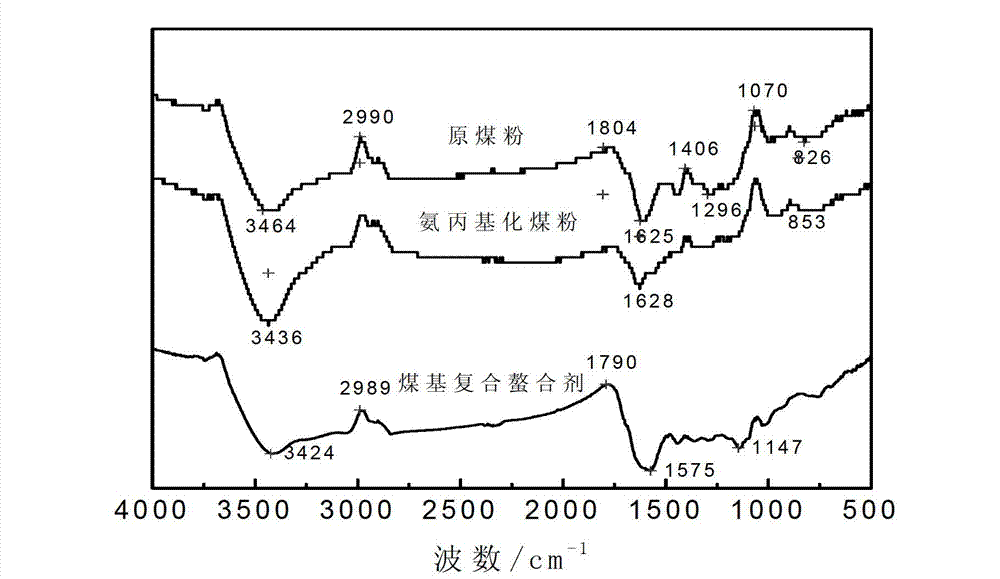

[0025] Now take raw coal powder 10g as example, the method for preparing coal-based composite chelating agent is made up of the following steps:

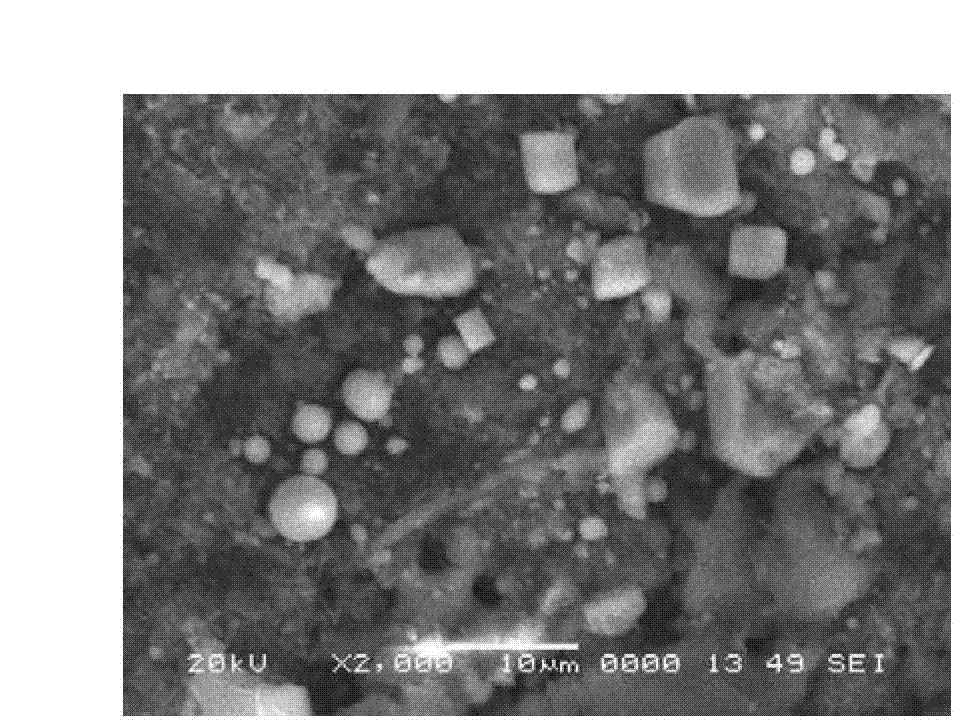

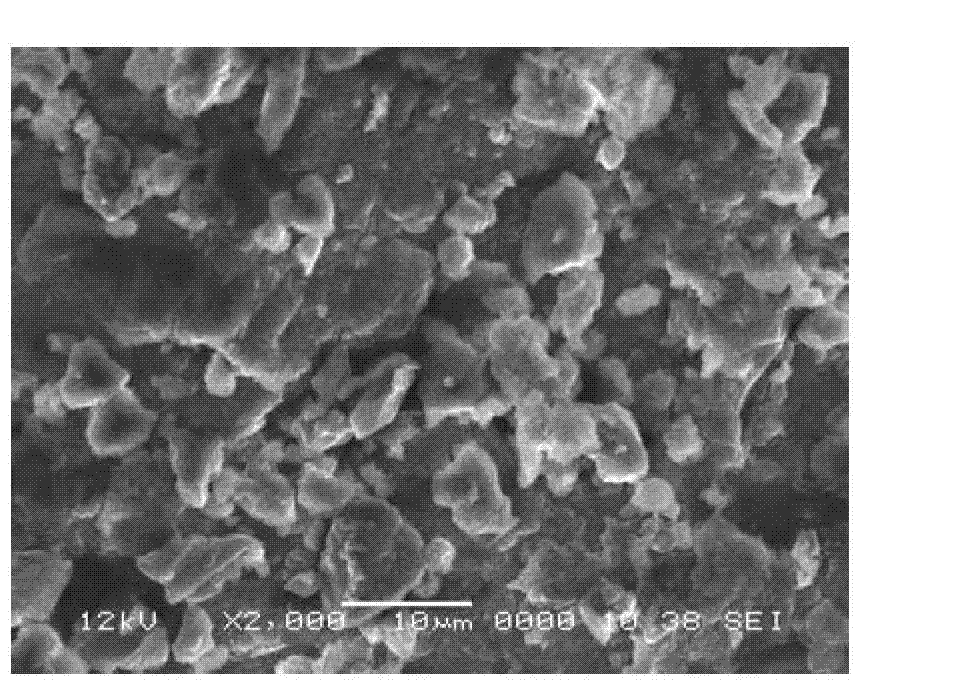

[0026] (1) Take 10g of coal powder with a particle size of 0.075mm, add 0.6g of γ-aminopropyltriethoxysilane and mix thoroughly for 3 hours. The mass ratio of coal powder to γ-aminopropyltriethoxysilane is 1:0.06 to obtain modified coal powder particles.

[0027] (2) Weigh 10g of the modified coal powder particles prepared in step (1) and place them in 12mL of acrylic acid, react at 75°C for 4 hours, wash with water twice, and dry to constant weight in an incubator at 80°C to obtain Ampyl Based coal powder particles;

[0028] (3) Dissolve 10g of sodium carbonate in 10g of hydroxylamine hydrochloride, add 10g of aminopropylated coal powder, the mass ratio of aminopropylated coal powder to sodium carbonate and hydroxylamine hydrochloride is 1:1:1, mix well , under the condition of a 90°C water bath to keep a constant temperature rea...

Embodiment 2

[0030] Now take raw coal powder 10g as example, the method for preparing coal-based composite chelating agent is made up of the following steps:

[0031] (1) Take 10g of coal powder with a particle size of 0.075mm, add 0.4g of γ-aminopropyltriethoxysilane and mix thoroughly for 3 hours. The mass ratio of coal powder to γ-aminopropyltriethoxysilane is 1:0.04 to obtain modified coal powder particles.

[0032] (2) Weigh 10g of the modified coal powder particles prepared in step (1) and place them in 10mL of acrylic acid, react at 75°C for 4 hours, wash with water twice, and dry to constant weight in an incubator at 80°C to obtain Ampyl Based coal powder particles;

[0033](3) Dissolve 6g of sodium carbonate in 6g of hydroxylamine hydrochloride, add 10g of aminopropylated coal powder, the mass ratio of aminopropylated coal powder to sodium carbonate and hydroxylamine hydrochloride is 1:0.6:0.6, mix well , under the condition of a 90°C water bath to keep a constant temperature re...

Embodiment 3

[0035] Now take raw coal powder 10g as example, the method for preparing coal-based composite chelating agent is made up of the following steps:

[0036] (1) Take 10g of coal powder with a particle size of 0.075mm, add 0.8g of γ-aminopropyltriethoxysilane and mix thoroughly for 3 hours. The mass ratio of coal powder to γ-aminopropyltriethoxysilane is 1:0.08 to obtain modified coal powder particles.

[0037] (2) Weigh 10g of the modified coal powder particles prepared in step (1) and place them in 15mL of acrylic acid, react at 75°C for 4 hours, wash with water twice, and dry to constant weight in an incubator at 80°C to obtain aminopropanol Based coal powder particles;

[0038] (3) Dissolve 16g of sodium carbonate in 16g of hydroxylamine hydrochloride, add 10g of aminopropylated coal powder, the mass ratio of aminopropylated coal powder to sodium carbonate and hydroxylamine hydrochloride is 1:1.6:1.6, mix well , under the condition of a 90°C water bath to keep a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com