Method for preparing glyceride carbonate by using loop reaction device

A glycerol carbonate and reaction device technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of methanol discharge to the environment, complex purification operation, poor mass transfer and heat transfer efficiency, etc. , to achieve the effect of improving product quality, increasing mass transfer efficiency and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

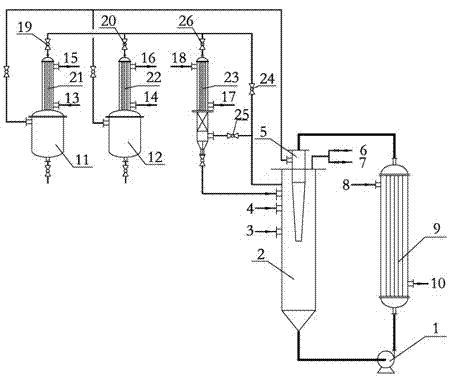

Embodiment 1

[0018] Add 50 kg of glycerin, 67 kg of dimethyl carbonate and 2.4 kg of NaOH catalyst into the 200 L loop reactor 2, and replace the system with nitrogen to maintain the reaction pressure of the entire loop system at a nitrogen pressure of 0.01 MPa, and start the loop cycle Pump 1, which is sent to the external circulation heat exchanger 9 by the loop circulation pump 1, and reaches the Venturi injector 5 at the top of the loop reactor 2 after being heated by the heat transfer oil, and enters the loop reactor 2 to form a circulating flow At the same time, the temperature is raised to 70°C, and the methanol generated by the reaction forms methanol vapor and a part of dimethyl carbonate and nitrogen at a high temperature and enters the separation tower 23 at the top of the loop reactor 2, and the temperature at the top of the separation tower 23 is 60°C. Part of the dimethyl carbonate is condensed and refluxed from the bottom of the separation tower 23 to the loop reactor 2, whil...

Embodiment 2

[0020] 50 kg glycerol, 67 kg dimethyl carbonate and 0.7 kg K 2 CO 3The catalyst is added to the 200 L loop reactor 2, and the system is replaced with nitrogen to maintain the reaction pressure of the entire loop system at a nitrogen pressure of 0.1 MPa. The loop circulation pump 1 is turned on, and the loop circulation pump 1 sends it to the external circulation The heat exchanger 9 reaches the Venturi injector 5 at the top of the loop reactor 2 after being heated by the heat transfer oil, and enters the loop reactor 2 through injection to form a circulating flow, and at the same time raises the temperature to 85 °C, and the methanol generated by the reaction is formed at a high temperature Methanol vapor, a part of dimethyl carbonate and nitrogen enter the separation tower 23 at the upper part of the loop reactor 2, and the temperature at the top of the separation tower 23 is 75°C, most of the dimethyl carbonate is condensed and refluxed from the bottom of the separation towe...

Embodiment 3

[0022] Add 50 kg of glycerin, 50 kg of dimethyl carbonate and 0.8 kg of CaO catalyst into the 200 L loop reactor 2, and replace the system with nitrogen to maintain the reaction pressure of the entire loop system at a nitrogen pressure of 0.01 MPa, and start the loop cycle Pump 1, which is sent to the external circulation heat exchanger 9 by the loop circulation pump 1, and reaches the Venturi injector 5 at the top of the loop reactor 2 after being heated by the heat transfer oil, and enters the loop reactor 2 to form a circulating flow At the same time, the temperature is raised to 80°C, and the methanol generated by the reaction forms methanol vapor and a part of dimethyl carbonate and nitrogen at a high temperature and enters the separation tower 23 at the top of the loop reactor 2, and the temperature at the top of the separation tower 23 is 65°C. Part of the dimethyl carbonate is condensed and refluxed from the bottom of the separation tower 23 to the loop reactor 2, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com