Method for preparing high-purity heme on large scale and application of heme

A large-scale preparation of heme technology, applied in the biological field, can solve the problems of health hazards for production personnel, difficulty in large-scale production, and large-scale environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

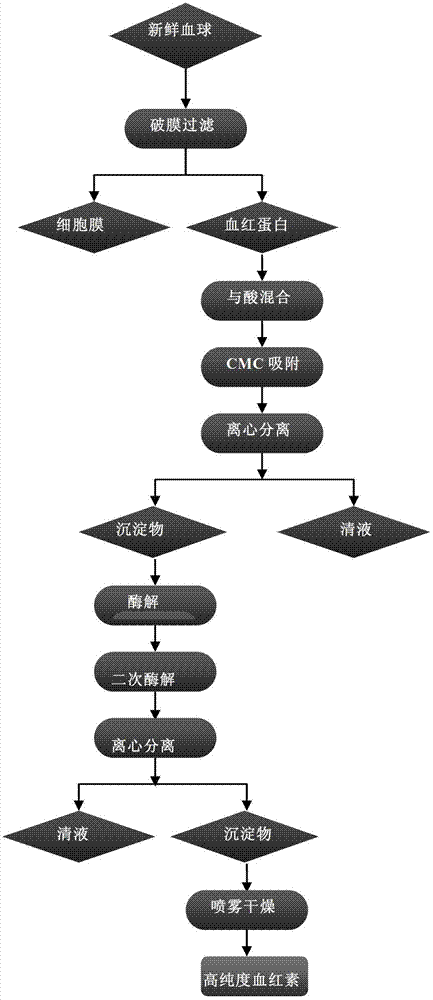

Method used

Image

Examples

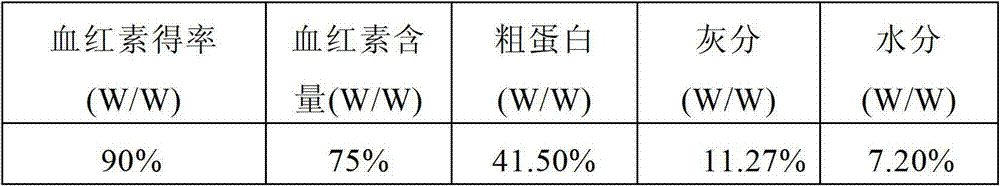

Embodiment 1

[0105] Production of high-purity heme iron from pig blood

[0106] (1) Mix 3 tons of blood cells from pigs with 12 tons of pure water and stir for 8 hours to obtain hemoglobin liquid (ie hemoglobin liquid I) with membrane rupture; the blood cells are fresh and healthy blood cells; the water is pure water;

[0107] (2) 15 tons of hemoglobin liquid I of membrane rupture is adopted tubular centrifugation to remove cell membrane; the centrifugal speed is 12000 rpm, and the discharge from the slag outlet at the lower end is cell membrane;

[0108] (3) Mix 20 kg of hydrochloric acid (concentration 38% (w / v)) with 63 kg of pure water (the final concentration of hydrochloric acid is about 9% (w / v)), and slowly add it to the 15 tons of hemoglobin solution that has been removed from the membrane. Stir for 3 hours, heme and globin are separated, and a mixture of heme and globin is obtained; the pH is about 3;

[0109] (4) Slowly add 3 tons of 1% CMC-NA into 15 tons of the mixed solution...

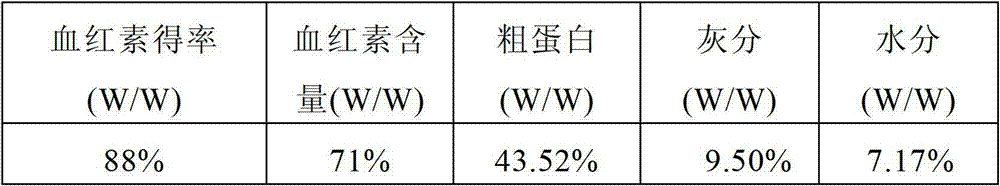

Embodiment 2

[0120] Production of heme iron from poultry blood

[0121] (1) Mix 3 tons of blood cells from poultry with 12 tons of pure water, stir for 8 hours to obtain hemoglobin liquid with ruptured membranes, and obtain hemoglobin liquid I; the blood cells are fresh and healthy blood cells; the water is pure water;

[0122] (2) The 15 tons of hemoglobin liquid with ruptured membranes was centrifuged by tube to remove cell membranes; the centrifugal speed was 12000 rpm, and the discharge from the slag outlet at the lower end was cell membranes;

[0123] (3) Mix 20 kg of hydrochloric acid (concentration 38% (w / v)) with 63 kg of pure water (the final concentration of hydrochloric acid is about 9% (w / v)), slowly add 15 tons of hemoglobin solution without membrane, and stir After 3 hours, a mixture of heme and globin was obtained; the pH was about 3;

[0124] (4) Slowly add 3 tons of 1% CMC-NA to 15 tons of the mixed solution, stir for 3 hours, and let stand for 10 hours to obtain the mixe...

Embodiment 3

[0135] Viscosity adjustment experiment

[0136] (1) Mix 3 tons of blood cells from poultry with 6 tons of pure water, stir for 8 hours to obtain hemoglobin liquid with ruptured membranes, and obtain hemoglobin liquid I; the blood cells are fresh and healthy blood cells; the water is pure water;

[0137] (2) Centrifuge the 9 tons of hemoglobin solution with membrane rupture to remove the cell membrane; the centrifugal speed is 12000 rpm, and the discharge from the slag outlet at the lower end is the cell membrane;

[0138] (3) Mix 20 kg of hydrochloric acid (concentration 38% (w / v)) with 63 kg of pure water (the final concentration of hydrochloric acid is about 9% (w / v)), slowly add 9 tons of hemoglobin solution without membrane, and stir After 3 hours, a mixture of heme and globin was obtained; the pH was about 3;

[0139] (4) Slowly add 3 tons of 5% CMC-NA to 9 tons of the mixed solution, stir for 3 hours, and let stand for 10 hours to obtain the mixed solution II of hemoglo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com