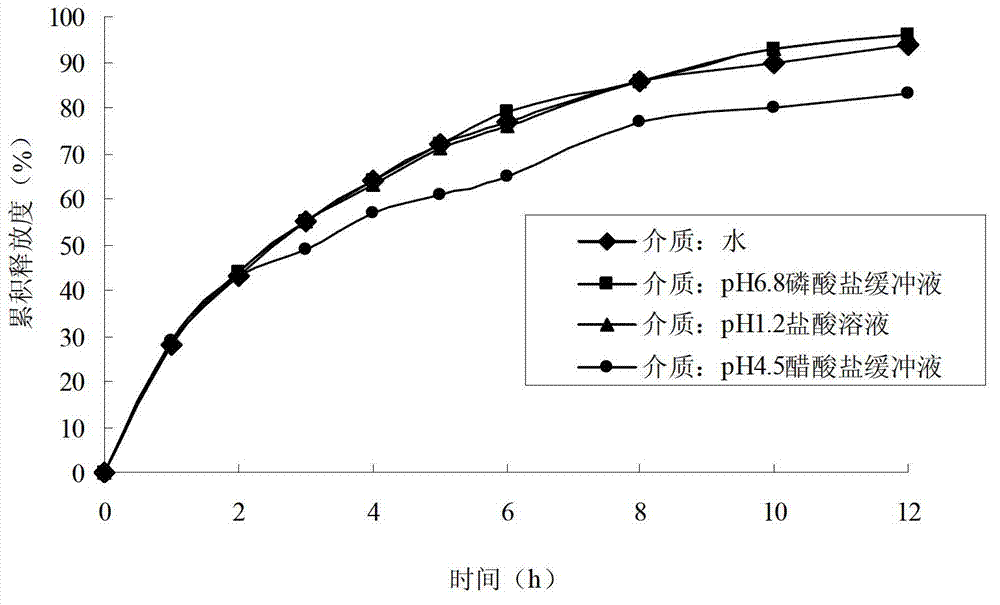

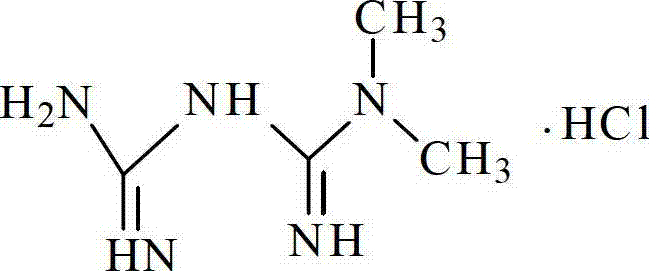

Novel metformin hydrochloride sustained release pellets and preparation method thereof

A technology for metformin hydrochloride and sustained-release pellets, which is applied in the field of pharmaceutical preparations, can solve the problem that there is no metformin hydrochloride sustained-release pellets, etc., and achieves the effects of masking bad odor, enhancing drug stability, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The percentage in the prescription is the percentage by weight of the component in the entire prescription, and the percentage of lipid material is calculated by the weight of the pill core, which is the same in the following examples.

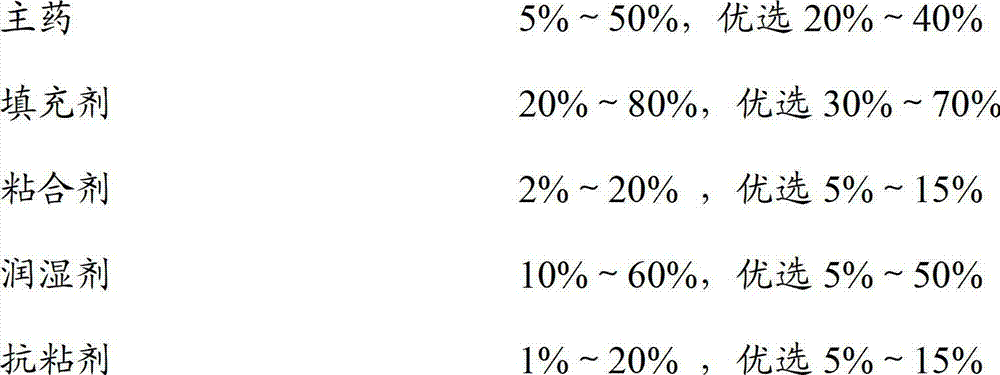

[0039] (1) Components containing pill core:

[0040]

[0041] (2) Components of the sustained-release coating layer:

[0042] Glyceryl monostearate 10% to 50%, preferably 15% to 40%

[0043] To prepare metformin hydrochloride extended-release pellets:

[0044] Step 1: Mix metformin hydrochloride and lactose evenly, add a solution of hypromellose and water, and make the powder into a wet and uniform soft material with certain plasticity;

[0045] Step 2: Put the soft material in an extruder to extrude, put the extruded product in a spheronizer and spheronize, add an appropriate amount of talc powder during the spheronization process, spheronize to form a pellet core, and dry to obtain a pill core;

[0046] Step 3: Place the pill core...

Embodiment 2

[0054] (1) Components containing pill core:

[0055]

[0056] (2) Components of the sustained-release coating layer:

[0057] Glyceryl tristearate 10% to 50%, preferably 15% to 40%

[0058] To prepare metformin hydrochloride extended-release pellets:

[0059] Step 1: Mix metformin hydrochloride and microcrystalline cellulose evenly, add a uniformly mixed solution of starch and water, and make the powder into a moist and uniform soft material with certain plasticity;

[0060] Step 2: Put the soft material in an extruder to extrude, put the extruded product in a spheronizer and spheronize, add an appropriate amount of talc powder during the spheronization process, spheronize to form a pellet core, and dry to obtain a pill core;

[0061] Step 3: Place the pill core in a fluidized bed coating machine, heat to melt tristearin, coat it, and dry it to obtain metformin hydrochloride sustained-release pellets.

[0062] Atomization pressure: 0.254mpa

[0063] Wind speed: 6~7m / s ...

Embodiment 3

[0069] (1) Components containing pill core:

[0070]

[0071] (2) Components of the sustained-release coating layer:

[0072] Glyceryl behenate 10% to 50%, preferably 15% to 40%

[0073] To prepare metformin hydrochloride extended-release pellets:

[0074] Step 1: Mix metformin hydrochloride and lactose evenly, add a solution of polyvinylpyrrolidone and water, and make the powder into a moist and uniform soft material with certain plasticity;

[0075] Step 2: Put the soft material in an extruder to extrude, put the extruded product in a spheronizer and spheronize, add an appropriate amount of magnesium stearate during the spheronization process, spheronize to form a pellet core, and dry to obtain a pill core;

[0076] Step 3: Put the pill core containing the drug in a fluidized bed coating machine, heat to melt the glyceryl behenate, coat it, and dry it to obtain metformin hydrochloride sustained-release pellets.

[0077] Atomization pressure: 0.254mpa

[0078] Wind spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com