Azithromycin capsule and preparation method thereof

A technology for azithromycin and capsules, applied in the field of pharmaceutical preparations, can solve the problems of product quality and stability, hidden dangers of clinical safety use, difficult control of moisture indicators, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

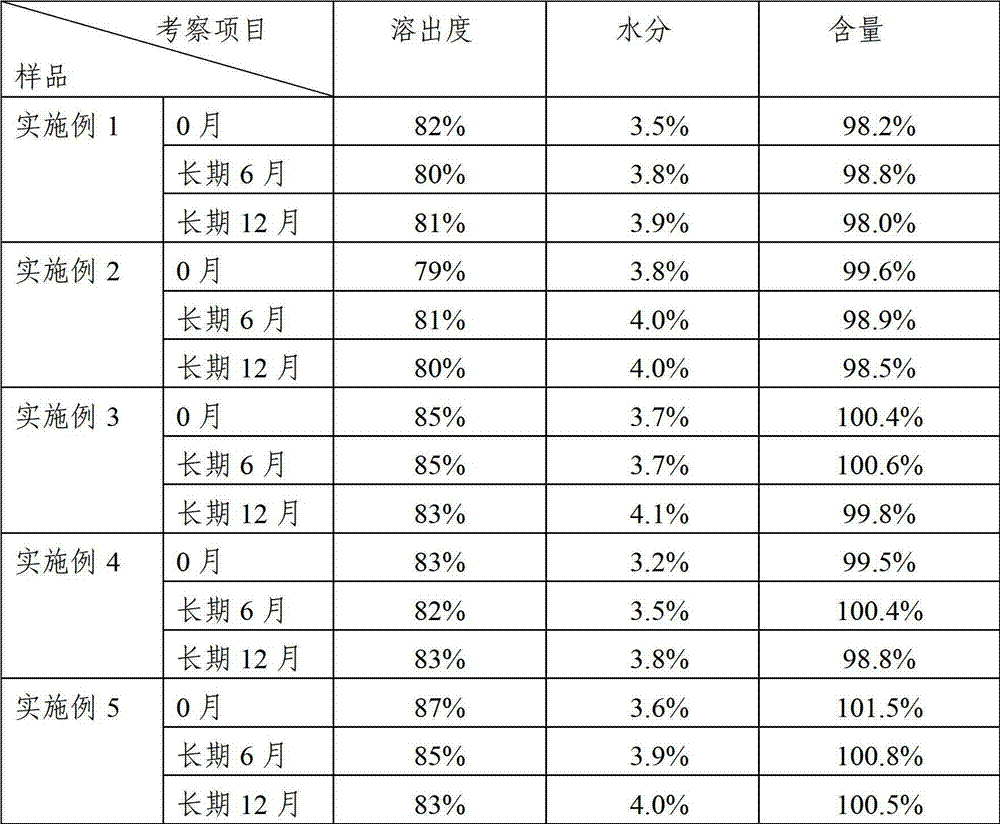

Examples

Embodiment 1

[0034] Formulation composition (parts by weight):

[0035] Azithromycin: 1 part;

[0036] Pregelatinized starch: 0.5 parts;

[0037] Aqueous solution of polyvinylpyrrolidone (5wt%): 0.02 parts;

[0038] Talcum powder: 0.05 part;

[0039] Magnesium stearate: 0.08 parts.

[0040] The preparation method is as follows:

[0041] (1) Crush each raw material separately, pass through a 100-mesh sieve, and weigh for later use.

[0042] (2) Mix azithromycin and pregelatinized starch evenly, and then add an aqueous solution of polyvinylpyrrolidone as a binder to make a soft material.

[0043] (3) Add talcum powder and magnesium stearate, use the extrusion and spheroidizing method to prepare pellets, control the moisture content of the pellets below 4.0%, and fill the obtained pellets into capsule shells.

Embodiment 2

[0045] Formulation composition (parts by weight):

[0046] Azithromycin: 1 part;

[0047] Pregelatinized starch: 0.4 parts;

[0048] Ethanol solution of polyvinylpyrrolidone (5wt%): 0.04 parts;

[0049] Talcum powder: 0.4 part;

[0050] Magnesium stearate: 0.08 parts.

[0051] The preparation method is as follows:

[0052] (1) Crush each raw material separately, pass through a 100-mesh sieve, and weigh for later use.

[0053] (2) Mix azithromycin and pregelatinized starch evenly, then add polyvinylpyrrolidone ethanol solution as adhesive to make soft material.

[0054] (3) Add talcum powder and magnesium stearate, use the extrusion and spheroidizing method to prepare pellets, control the moisture content of the pellets below 4.0%, and fill the obtained pellets into capsule shells.

Embodiment 3

[0056] Formulation composition (parts by weight):

[0057] Azithromycin: 1 part;

[0058] Pregelatinized starch: 0.8 parts;

[0059] Aqueous solution of polyvinylpyrrolidone (8wt%): 0.06 parts;

[0060] Talcum powder: 0.3 parts;

[0061] Magnesium stearate: 0.15 parts.

[0062] The preparation method is as follows:

[0063] (1) Crush each raw material separately, pass through a 100-mesh sieve, and weigh for later use.

[0064] (2) Mix azithromycin and pregelatinized starch evenly, and then add an aqueous solution of polyvinylpyrrolidone as a binder to make a soft material.

[0065] (3) Add talcum powder and magnesium stearate, use the extrusion and spheroidizing method to prepare pellets, control the moisture content of the pellets below 4.0%, and fill the obtained pellets into capsule shells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com