Magnetic hollow multihole carbon ball with core-shell structure and preparation method of magnetic hollow multihole carbon ball

A core-shell structure, hollow porous technology, which is applied in the preparation of microspheres, the magnetic properties of inorganic materials, and the preparation of microcapsules. , the effect of regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

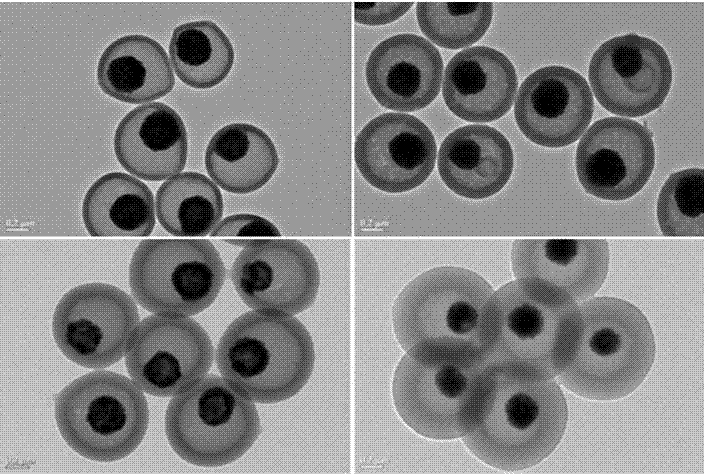

[0021] Embodiment 1: The ferroferroic oxide magnetic cluster is about 250nm, and the thickness of the phenolic resin shell layer is about 60nm.

[0022] 10-200 mg Fe 3 o 4 The nanoclusters are dispersed in deionized water, then 1-20 mL of styrene and 10-200 mg of potassium persulfate are added, and soap-free emulsion polymerization is carried out in nitrogen for 2-6 hours to obtain Fe 3 o 4 PS composite microspheres. will get Fe 3 o 4 PS composite microspheres were dispersed in deionized water, added 0.1-2 mL formaldehyde, 40 mg phenol and 0.15 mL ammonia water and transferred to a microwave tube to react under microwave irradiation. The microwave reaction temperature was 120°C-200°C, the reaction time was 40 min, and the microwave tube was cooled to room temperature and taken out. The product was separated by magnetic separation, and the reactant was washed with deionized water and absolute ethanol, and dried in a vacuum oven at 50° C. for 4 hours. Will Fe 3 o 4 PSPF...

Embodiment 2

[0023] Example 2: The magnetic cluster of ferroferrogen tetroxide is about 250nm, and the thickness of the shell layer of phenolic resin is 90nm.

[0024] The steps are the same as those described in Example 1, except that the amount of phenol is changed from 40 mg to 60 mg.

Embodiment 3

[0025] Example 3: The ferroferrogen tetroxide magnetic cluster is about 250 nm, and the thickness of the phenolic resin shell layer is 120 nm.

[0026] The steps were the same as described in Example 1, except that the amount of phenol was changed from 40 mg to 90 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com