Method for preparing metal micro-nano array electrode by using ZnO crystal as template

An array electrode, micro-nano technology, applied in the manufacture of micro-structure devices, metal material coating technology, micro-structure technology, etc., can solve the problems of not appearing, preparing micro-nano array electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

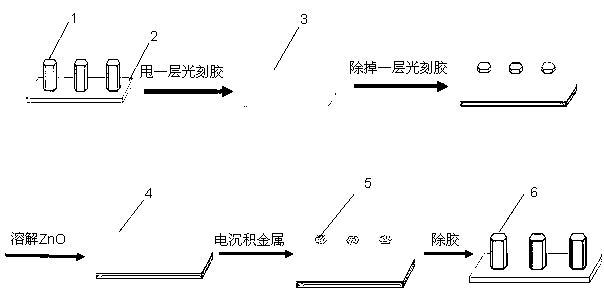

[0035] Example 1: Preparation of Ni micro-nano array electrodes with hexagonal prisms.

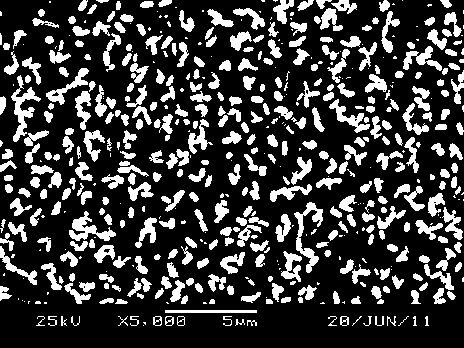

[0036] Preparation of ZnO crystal array with hexagonal column shape: ZnO is electrodeposited on ITO (indium tin oxide) / glass substrate. First, clean the ITO / glass with ethanol, acetone, and 1M NaOH respectively for 10 minutes; then configure the solution and prepare 20ml of 5×10 -4 M zinc acetate, add 0.164g sodium acetate to it and mix well. Using a three-electrode system (ITO as the working electrode, Pt as the counter electrode, and Ag / AgCl electrode as the reference electrode), set the potential at -0.95V, the temperature at 75°C, and electrodeposition for 45 minutes to obtain ZnO micro-nano arrays. Such as figure 1 shown.

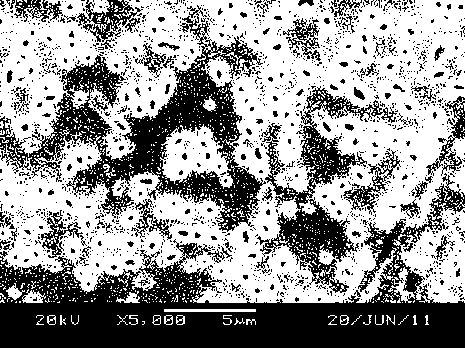

[0037] Preparation of the template: Spin a layer of photoresist S1805 on the ZnO micro-nano array with a glue spinner at 1000 rpm, and heat-treat at 90°C for 60 minutes to stabilize the photoresist. Then immerse in the corresponding photoresist treatment soluti...

Embodiment 2

[0040] Embodiment 2: Preparation of hexagonal prism-shaped Co crystal micro-nano array electrode: use the same method in Example 1 to prepare a template, and measure 10ml of Co(NO) containing 132g per liter. 3 ) 2 ·6H 2 O, 25gH 3 BO 3 In the mixed solution, use a three-electrode system (the template is the working electrode, Pt is the counter electrode, and the Ag / AgCl electrode is the reference electrode), set the deposition potential to -0.9V, electrodeposit for 1-20min, and then immerse in the degumming solution ethanol 2-30min to remove the photoresist.

Embodiment 3

[0041] Example 3: Preparation of hexagonal Bi micro-nano array electrode: use the same method in Example 1 to prepare a template, and get 0.005M Bi 2 (NO 3 ) 2 Solution 0.4ml, add 6ml of acetic acid / sodium acetate buffer solution, use three-electrode system (template as working electrode, Pt as counter electrode, Ag / AgCl electrode as reference electrode), set deposition potential -0.7V, electrodeposition for 30min, Then immerse in ethanol for 2-30min to remove the photoresist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com