Food packaging latex as well as preparation method and application thereof

A food packaging and latex technology, applied in the field of new polymer materials, can solve the problems of unproposed latex for food packaging, complex production process, and high equipment requirements, and achieve improved vacuum desorption effect, good packaging, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

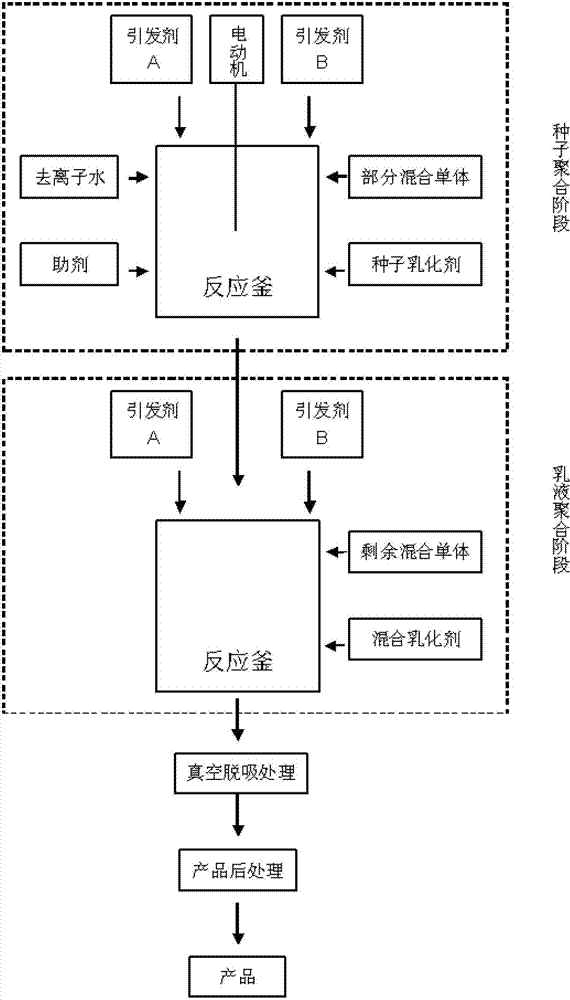

Method used

Image

Examples

Embodiment 1

[0029] (1) Mixed monomer preparation: mix 89kg of vinylidene chloride, 4.5kg of 2-ethylhexyl acrylate, and 0.5kg of acrylonitrile, stir for 2 hours, and set aside;

[0030] (2) Preparation of mixed polymeric emulsifier: mix 1.2kg of COPS-1, 1kg of 2A-1 emulsifier, and 6kg of methacrylic acid, dilute with water to 20kg, stir and mix at high speed, and set aside;

[0031] (3) Initiator preparation: Dilute 80 g of tert-butyl hydroperoxide and 80 g of sodium formaldehyde sulfoxylate to a concentration of 2% by mass, and set aside;

[0032] (4) Seed polymerization reaction: Add 64kg of deionized water or soft water, 20g of ammonium acetate additive, 1g of ferrous chloride, 120g of seed polymerization emulsifier sodium dodecylbenzenesulfonate, and 280g of MA-80 into a 200L reactor In the process, seal the kettle, replace with nitrogen for 3 times, vacuumize, inhale 5% (weight) of the mixed monomer prepared in step 1, cold disperse for 0.5h, heat up to 47°C, and pump continuously at ...

Embodiment 2

[0042](1) Mixed monomer preparation: mix 91kg of vinylidene chloride, 4.5kg of 2-ethylhexyl acrylate, and 0.5kg of acrylonitrile, stir for 2 hours, and set aside;

[0043] (2) Preparation of mixed polymeric emulsifier: mix 1.2kg of COPS-1, 1kg of 2A-1 emulsifier, and 4kg of methacrylic acid, dilute with water to 20kg, stir and mix at high speed, and set aside;

[0044] (3) Initiator preparation: Dilute 80 g of tert-butyl hydroperoxide and 80 g of sodium formaldehyde sulfoxylate to a concentration of 2% by mass, and set aside;

[0045] (4) Seed polymerization reaction: Add 64kg of deionized water or soft water, 20g of ammonium acetate additive, 1g of ferrous chloride, 120g of seed polymerization emulsifier sodium dodecylbenzenesulfonate, and 280g of MA-80 into a 200L reactor In the process, seal the kettle, replace with nitrogen for 3 times, vacuumize, inhale 5% (weight) of the mixed monomer prepared in step 1, cold disperse for 0.5h, heat up to 47°C, and pump continuously at a...

Embodiment 3

[0048] (1) Mixed monomer preparation: mix 90kg of vinylidene chloride, 5.7kg of 2-ethylhexyl acrylate, and 0.3kg of acrylonitrile, stir for 2 hours, and set aside;

[0049] (2) Preparation of mixed polymeric emulsifier: mix 1.2kg of COPS-1, 1kg of 2A-1 emulsifier, and 4kg of methacrylic acid, dilute with water to 20kg, stir and mix at high speed, and set aside;

[0050] (3) Initiator preparation: Dilute 80 g of tert-butyl hydroperoxide and 80 g of sodium formaldehyde sulfoxylate to a concentration of 2% by mass, and set aside;

[0051] (4) Seed polymerization reaction: Add 64kg of deionized water or soft water, 20g of ammonium acetate additive, 1g of ferrous chloride, 120g of seed polymerization emulsifier sodium dodecylbenzenesulfonate, and 280g of MA-80 into a 200L reactor In the process, seal the kettle, replace with nitrogen for 3 times, vacuumize, inhale 5% (weight) of the mixed monomer prepared in step 1, cold disperse for 0.5h, heat up to 47°C, and pump continuously at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com