Hydrolysis-resistant polyester polyol and preparation method thereof

A polyester polyol and polyether polyol technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve poor hydrolysis resistance, low addition amount, adhesive performance, high temperature resistance And other problems such as poor performance, to achieve good hydrolysis resistance, improve adhesion, and enhance the effect of initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

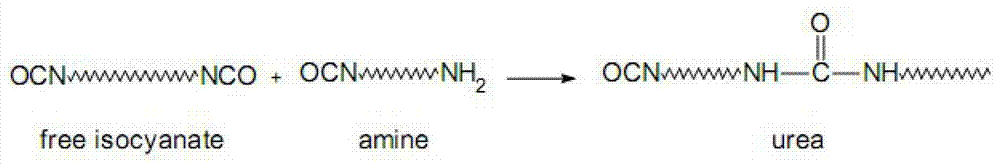

Problems solved by technology

Method used

Image

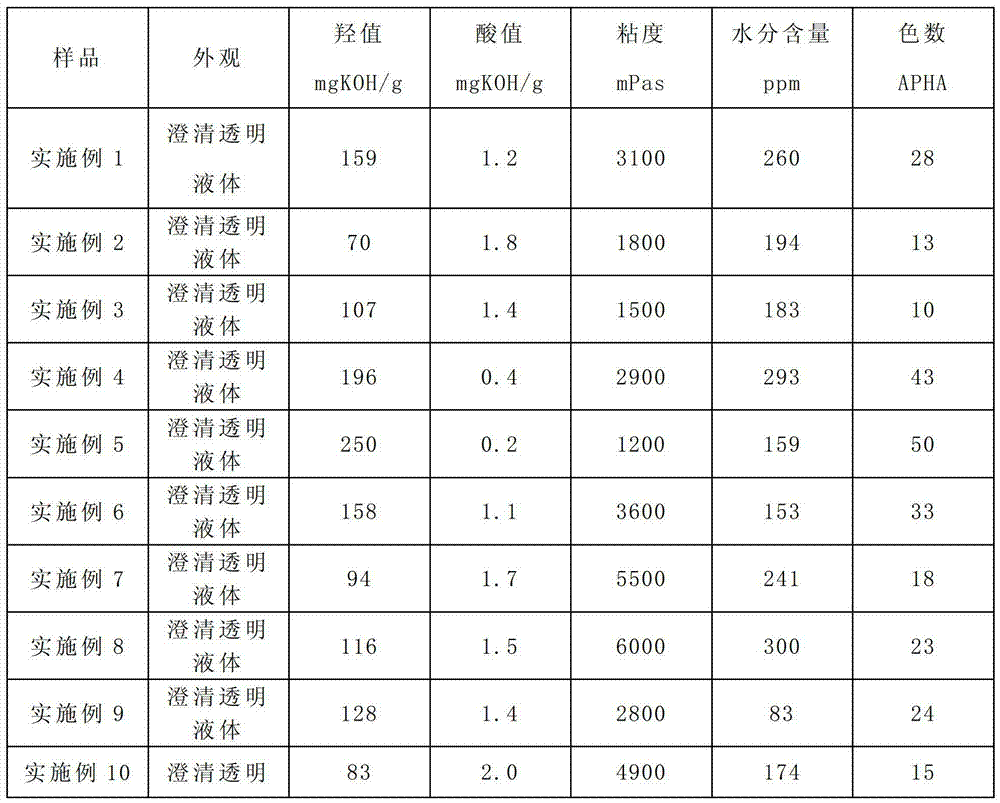

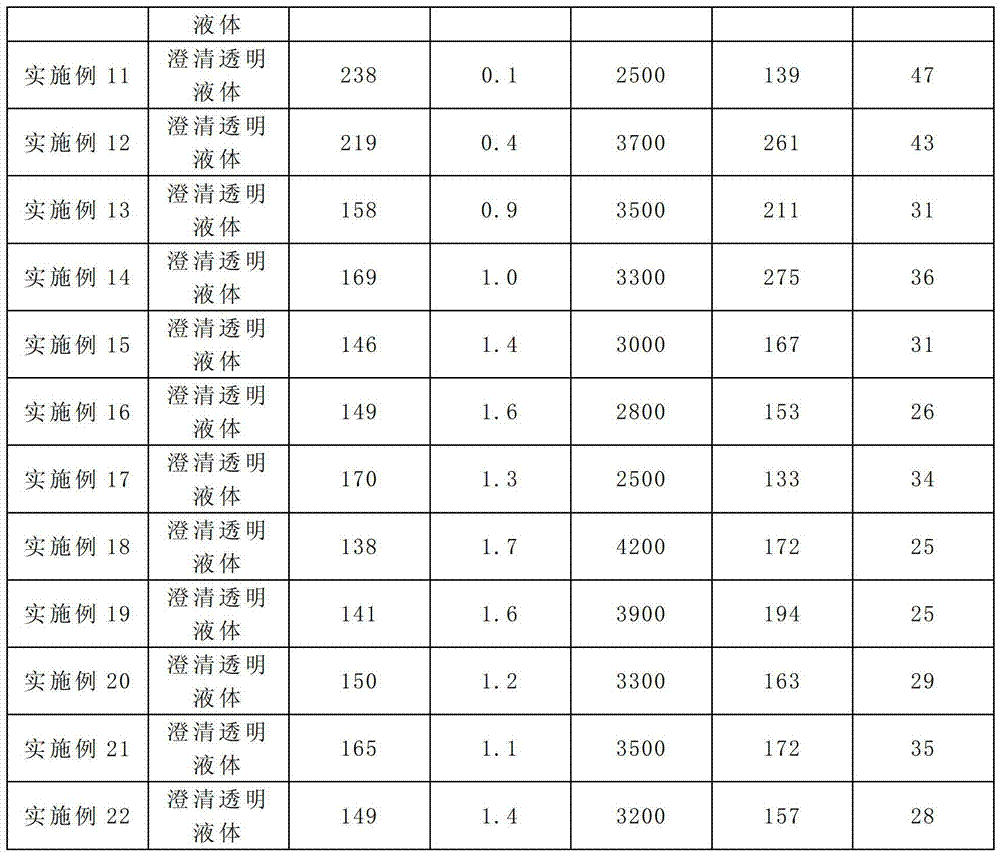

Examples

Embodiment 1

[0031] The hydrolysis-resistant polyester polyol is prepared from the following components by weight: 30 parts of succinic acid, 10 parts of isophthalic acid, 15 parts of ethylene glycol, and 0.0005 parts of stannous octoate.

[0032] Its preparation method comprises the following steps:

[0033] (1) Mix aliphatic dibasic carboxylic acid, aromatic dibasic acid or carboxylic acid anhydride and dihydroxy polyol under nitrogen protection to obtain mixed raw materials;

[0034] (2) Raise the temperature of the mixed raw materials to 150°C, and the reaction starts;

[0035] (3) Continue to heat up and vacuumize at the same time; when the temperature rises to 210°C and the vacuum reaches 300 mbar, add additives;

[0036] (4) When the temperature rises to 230°C and the vacuum reaches 20 mbar, distill under reduced pressure to reduce the pressure to 10 mbar;

[0037] (5) Distill under reduced pressure to a pressure of 3-5 mbar, and continue to distill until the acid value is below 2...

Embodiment 2

[0039] The hydrolysis-resistant polyester polyol is prepared from the following components by weight: 20 parts of succinic anhydride, 20 parts of terephthalic acid, 20 parts of diethylene glycol, and 0.0010 parts of dibutyltin dilaurate.

[0040] Its preparation method comprises the following steps:

[0041] (1) Mix aliphatic dibasic carboxylic acid, aromatic dibasic acid or carboxylic acid anhydride and dihydroxy polyol under nitrogen protection to obtain mixed raw materials;

[0042] (2) Raise the temperature of the mixed raw materials to 130°C, and the reaction starts;

[0043] (3) Continue to heat up and vacuumize at the same time; when the temperature rises to 190°C and the vacuum reaches 500 mbar, add additives;

[0044] (4) When the temperature rises to 220°C and the vacuum reaches 200 mbar, distill under reduced pressure to reduce the pressure to 30 mbar;

[0045] (5) Distill under reduced pressure to a pressure of 3-5 mbar, and continue to distill until the acid val...

Embodiment 3

[0047] The hydrolysis-resistant polyester polyol is made of the following components in parts by weight: 40 parts of adipic acid, 5 parts of dimethyl terephthalate, 25 parts of 1,2-propylene glycol, and 0.0015 parts of dibutyltin.

[0048] Its preparation method comprises the following steps:

[0049] (1) Mix aliphatic dicarboxylic acid, aromatic dibasic acid or carboxylic acid anhydride and polyol under nitrogen protection to obtain mixed raw materials;

[0050] (2) Raise the temperature of the mixed raw materials to 140°C, and the reaction starts;

[0051] (3) Continue to heat up and vacuumize at the same time; when the temperature rises to 200°C and the vacuum reaches 400 mbar, add additives;

[0052] (4) When the temperature rises to 225°C and the vacuum reaches 100 mbar, distill under reduced pressure to reduce the pressure to 20 mbar;

[0053] (5) Distill under reduced pressure to a pressure of 3-5 mbar, and continue to distill until the acid value is below 2 and the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com