High-yield method for co-producing resistant dextrin, beta-cyclodextrin and F42 HFCS (high fructose corn syrup)

A technology of resistant dextrin and fructose syrup, applied in ion exchange regeneration, ion exchange, selective adsorption, etc., can solve the problems of high raw material consumption, waste of glucose syrup, low purity of resistant dextrin, etc., and achieve the improvement of raw material Utilization and yield, reducing the difficulty of refining process, reducing the effect of non-functional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

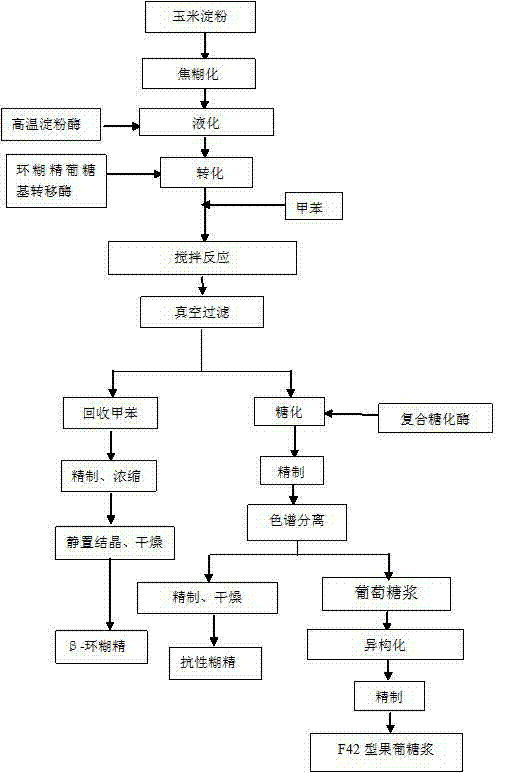

Image

Examples

Embodiment

[0021] 1 Charcoal gelatinization reaction: Add cornstarch to a heating device with a mixer, spray 1% hydrochloric acid while stirring, then mix well, heat slowly, and heat up to 150°C for 60 minutes to obtain pyrodextrin.

[0022] 2. Liquefaction: Make a 20% solution of pyrodextrin, adjust the pH to 5.8, add 0.5 L / ton of dry starch high-temperature α-amylase, and hydrolyze it at 105°C for 20 minutes to obtain crude resistant dextrin.

[0023] 3 Transformation: Cool down the temperature of the liquefied liquid to 58°C, the pH value is 7.0, add cyclodextrin glucosyltransferase at a concentration of 7 enzyme activity units per gram of starch, add 1% toluene, carry out stirring reaction for 64 hours, and then carry out vacuum Filter the insoluble compound, recover toluene, concentrate and refine, crystallize and dry to obtain the β-cyclodextrin product.

[0024] 4 Saccharification, chromatographic separation: after vacuum filtration, the solution is adjusted to pH 4.23, 0.9L / ton (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com