One-dimensional magnetic Fe-Co alloy/cobalt ferrite composite nano-fibers and preparation method thereof

A technology of composite nanofibers and cobalt ferrite, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, artificial filaments made of inorganic raw materials, etc., can solve the problems of complex process, unfavorable industrial production, long process, etc., and achieve simple preparation method, Improvement of high-frequency electromagnetic characteristics and enhancement of saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The method for preparing Fe-Co alloy / cobalt ferrite composite nanofibers provided by the invention mainly includes preparation of electrospinning solution, electrospinning process, preparation and reduction treatment of cobalt ferrite nanofibers. The steps are:

[0025] (1) The preparation of the electrospinning solution is mainly to prepare a solution with suitable viscosity and spinnability. The specific process is: add a certain amount of polymer into the corresponding solvent, stir magnetically at room temperature for 1 to 2 hours, then add an appropriate amount of metal inorganic salt according to the ratio of the amount of substances Co:Fe=1:2, and continue magnetically stirring for 3 hours. ~15h, until a uniform, transparent and stable spinning solution is formed. The metal inorganic salt is nitrate or acetate. The mass ratio of each component in the spinning solution is: polymer 4-15wt%, preferably 6-10wt%, inorganic salt 5-20wt%, preferably 8-15wt%, and the r...

Embodiment 1

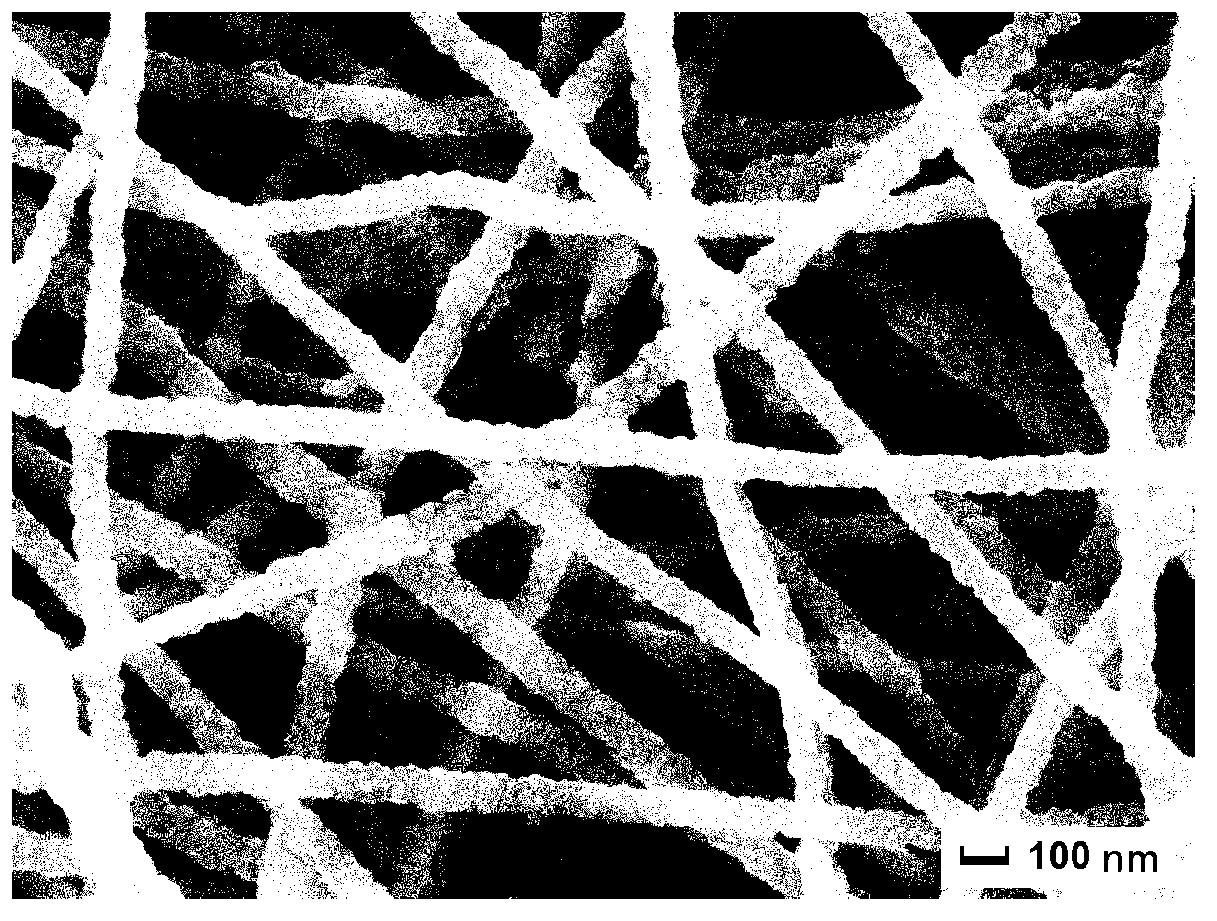

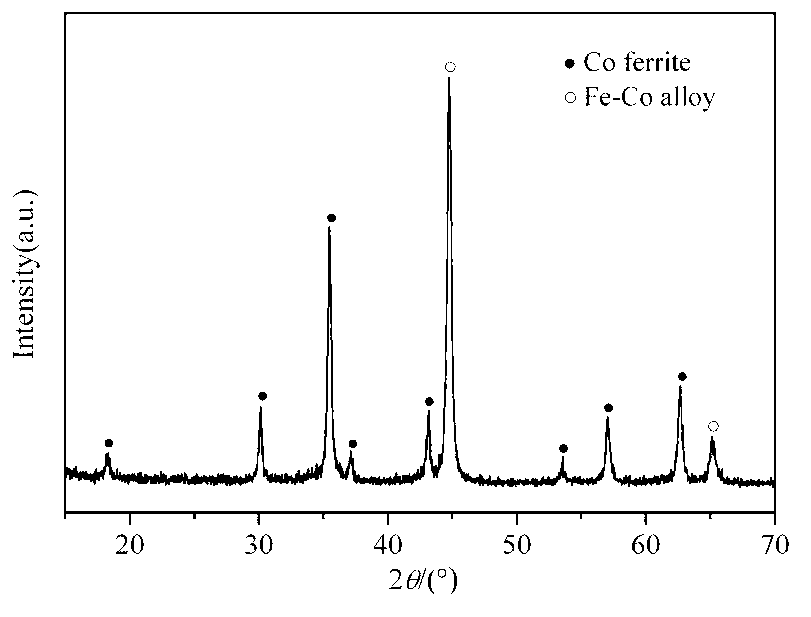

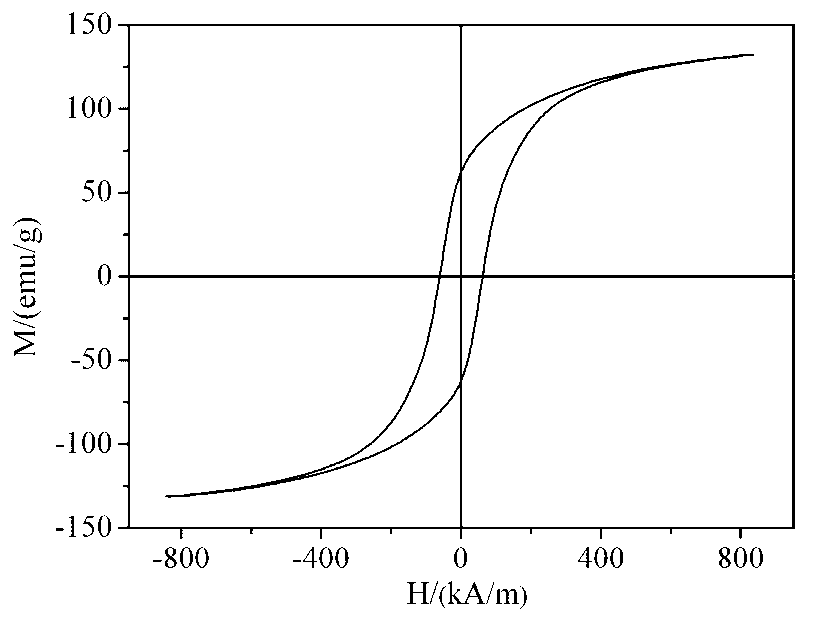

[0032]Add a certain amount of polyvinylpyrrolidone (PVP) with an average molecular weight of 1,300,000 to a mixed solvent composed of deionized water and absolute ethanol (water / alcohol ratio is 2 / 3), and stir magnetically at room temperature for about 1.5h until PVP Add appropriate amount of iron nitrate (Fe(NO 3 ) 3 9H 2 O) and cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), the quality of the two inorganic salts is determined by Co 2+ with Fe 3+ The ratio of the amount of substances is equal to the ratio of 1:2. Continue magnetic stirring for about 10 hours to prepare a uniform and transparent spinning solution, wherein the content of PVP is 6wt%, and the content of inorganic salt is 13wt%. The prepared solution was introduced into an electrospinning device for spinning. The spinning conditions were: voltage 15kV, the distance between the collector and the spinneret, that is, the solidification distance, 15cm, the solution propulsion rate 0.5mL / h, and the spinneret diameter 0....

Embodiment 2

[0034] Basic process is the same as embodiment 1. The difference is that the calcination temperature of cobalt ferrite nanofibers is 400°C, the content of the alloy phase in the prepared Fe-Co alloy / cobalt ferrite composite nanofibers is about 90wt%, and its saturation magnetization and coercion at room temperature The coercive force is about 190emu / g and 81kA / m respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com