High-density lithium ion battery anode material nickel-cobalt lithium aluminate and preparation method thereof

A lithium-ion battery, nickel-cobalt-aluminate lithium technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as being unsuitable for mass production, environmental pollution, and complex processes, achieving good consistency and low production costs. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

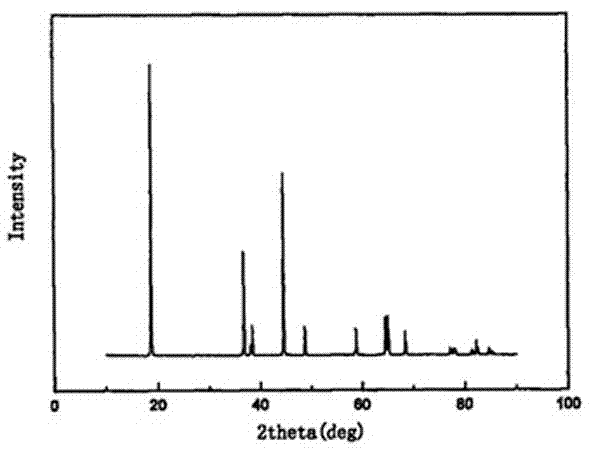

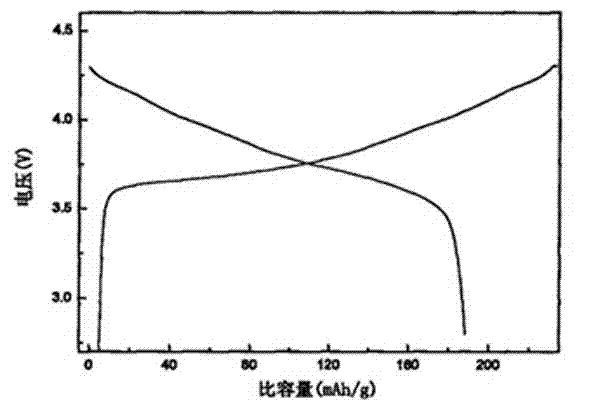

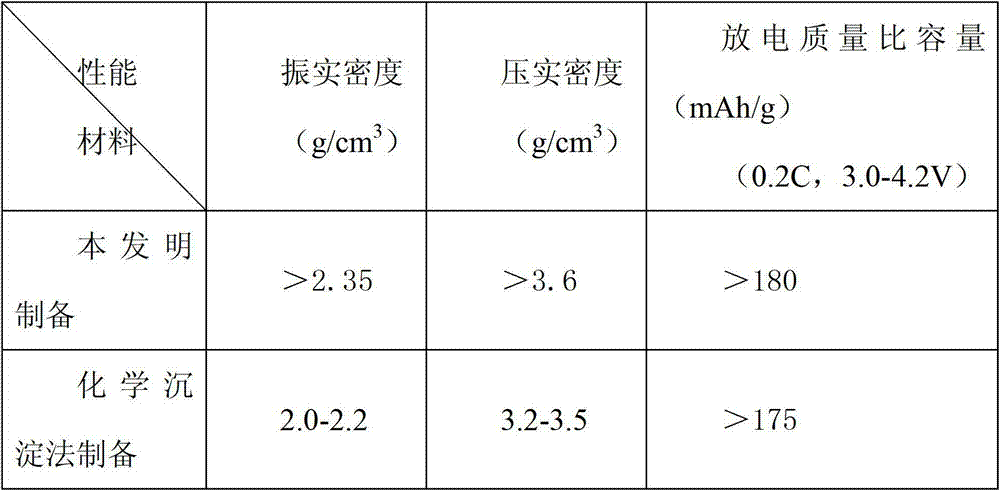

[0022] Weigh nickel hydroxide, cobalt carbonate, and aluminum hydroxide according to the ratio of ion molar ratio Ni:Co:Al=0.8:0.15:0.05 and put them in an inclined mixer, add 1 times the weight of polyurethane balls and ball mill and mix for 3 hours; The mixed raw materials were calcined at 650°C for 10 hours in a pusher-type resistance furnace, according to 15m 3 The flow rate of / h is fed into oxygen during calcination, then cooled to room temperature and taken out; crushed and classified to obtain the oxide of the intermediate product nickel-cobalt-aluminum; according to the ratio of the ion molar ratio of the oxide of the intermediate product nickel-cobalt-aluminum to 1.03 Weigh lithium carbonate, put it into an inclined mixer, add zirconia balls with a mass ratio of 1:1 (material weight / ball weight) and vibrate and mix for 4 hours; Calcined for 15h, according to 15m 3 Oxygen is introduced during calcination at a flow rate of / h, cooled naturally to room temperature, cru...

Embodiment 2

[0027] Weigh nickel hydroxide, cobalt hydroxide, aluminum hydroxide and niobium pentoxide in the ratio of ion molar ratio Ni: Co: Al: Nb = 0.8: 0.15: 0.045: 0.005 and put them in the inclined mixer, add 1 Polyurethane balls of twice the weight were mixed for 3 hours; the mixed raw materials were calcined at 600°C for 10 hours in a pusher-type resistance furnace. 3 The flow rate of / h is passed into air or oxygen during calcination, then cooled to room temperature and taken out; crushed and classified to obtain the oxide of the intermediate product nickel-cobalt-aluminum-niobium; according to the ion molar ratio of the oxide of the intermediate product nickel-cobalt-aluminum-niobium Weigh lithium carbonate at a ratio of 1.05, put it into an inclined mixer, add zirconia balls with a mass ratio of 1:1 (material weight / ball weight) and vibrate and mix for 4 hours; Calcined at 830℃ for 12h, according to 15m 3 Oxygen is introduced during calcination at a flow rate of / h, cooled nat...

Embodiment 3

[0030] Weigh nickel carbonate, cobalt carbonate, aluminum oxide and gallium oxide in the ratio of ion molar ratio Ni: Co: Al: Ga = 0.8: 0.15: 0.03: 0.02 and put them in the inclined mixer, add 1 times the weight Polyurethane balls were milled and mixed for 3 hours; the mixed raw materials were calcined at 650°C for 10 hours in a push-plate resistance furnace, according to 10m 3 The flow rate of / h is passed into air or oxygen during calcination, then cooled to room temperature and taken out; crushed and classified to obtain the oxide of the intermediate product nickel-cobalt-aluminum-gallium; according to the ion molar ratio of the oxide of the intermediate product nickel-cobalt-aluminum-gallium Weigh lithium carbonate at a ratio of 1.05, put it into an inclined mixer, add zirconia balls with a mass ratio of 1:1 (material weight / ball weight) and vibrate and mix for 4 hours; Calcined at 930°C for 12h, according to 20m 3 The flow rate of / h is passed into air during calcination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com