Negative photosensitive resin composition

A technology of photosensitive resin and composition, applied in optics, opto-mechanical equipment, instruments, etc., can solve the problems of inappropriate application, slow sensitivity, slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

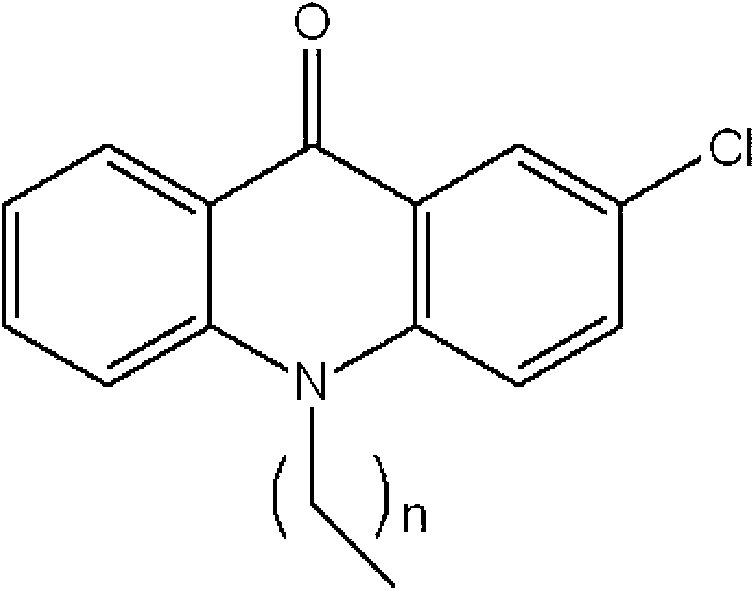

Method used

Image

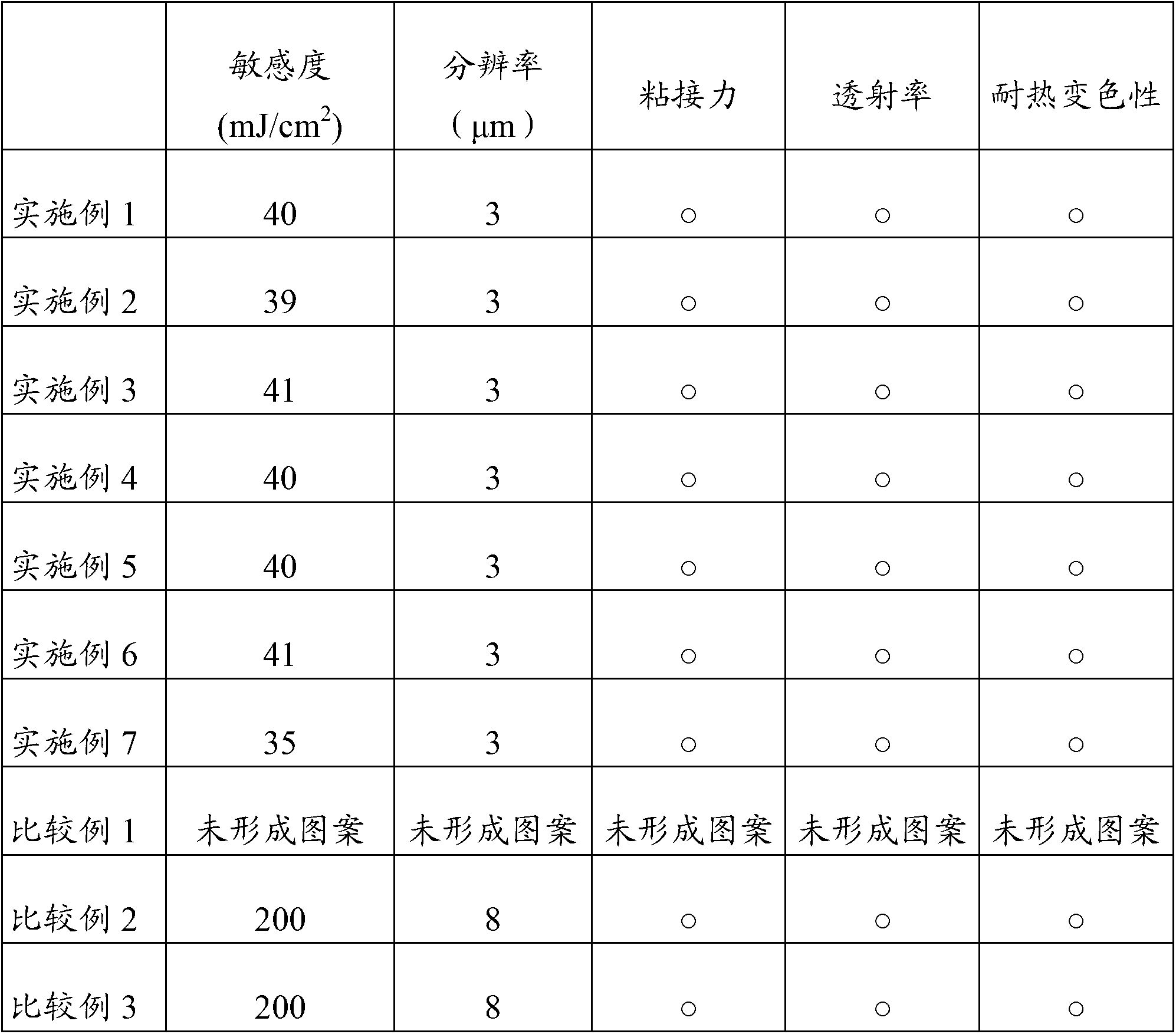

Examples

Synthetic example 1

[0056] Synthesis Example 1 (preparation of acrylic copolymer)

[0057] A mixed solution of 400 parts by weight of propylene glycol monoethyl ether acetate, 30 parts by weight of methacrylic acid, 30 parts by weight of styrene, and 40 parts by weight of aryl methacrylate was put into a flask equipped with a cooler and a stirrer. After the liquid composition was well mixed at 600 rpm in a mixing container, 15 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile) was added. Slowly raise the temperature of the polymerization mixed solution to 70°C, and maintain this temperature for 8 hours, then cool at room temperature, and add 500 ppm of hydroxybenzophenone as a polymerization inhibitor to obtain an acrylic copolymer with a solid content concentration of 20% by weight. thing. The weight average molecular weight of the obtained acrylic copolymer was 10,000. At this time, the weight average molecular weight is a polystyrene conversion average molecular weight measured using ...

Synthetic example 2

[0058] Synthesis example 2 (preparation of polyimide copolymer)

[0059]Add 50 parts by weight of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane and 50 parts by weight of 4,4-(hexafluoro-isopropylidene)diphthalic anhydride into a flask with a cooler and a stirrer parts by weight, and NMP400 parts by weight were added at room temperature, stirred for 24 hours, and reacted. At this time, the concentration of the solution was 20% by weight of solid matter. After that, in order to remove the water generated in the imidization reaction, the same amount of xylene as that of the NMP was added to the polyamic acid generated by the reaction, and reacted at 160° C. for 5 hours to prepare polyimide . Under a nitrogen atmosphere, after dissolving soluble polyimide (6FDA / BAPAF) in DMAc, drop methacryloyl chloride as a photosensitive group and an equivalent amount of triethylamine (TEA), and react at 0°C for 12 hours to prepare photosensitive polyimide copolymers. The weight average ...

Synthetic example 3

[0060] Synthesis Example 3 (preparation of siloxane copolymer)

[0061] Add 40 parts by weight of phenyltriethoxysilane, 20 parts by weight of tetraethoxysilane and 40 parts by weight of methacryloxypropyl trimethoxysilane as reactive silanes in a flask with a cooler and a stirrer , After adding 100 parts by weight of propylene glycol monoethyl ether acetate as a solvent and performing nitrogen substitution, it was stirred slowly. 40 parts by weight of ultrapure water and 3 parts by weight of oxalic acid used as a catalyst were further added to the reaction solution, and then stirred again slowly. One hour later, the temperature of the reaction solution was raised to 60° C., and the temperature was maintained for 10 hours. After solution polymerization, the reaction solution was cooled at room temperature to complete the reaction. Next, after removing the alcohol solvent and residual moisture generated during the reaction by vacuum drying, it was diluted with 300 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com