Mesoporous manganese-based composite metal oxide as well as preparation method and application thereof

A composite metal, mesoporous manganese-based technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of low specific surface area of materials, high operational risk, long process routes, etc., and achieve high specific surface area. , the preparation method and equipment are simple, and the raw materials are economical and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

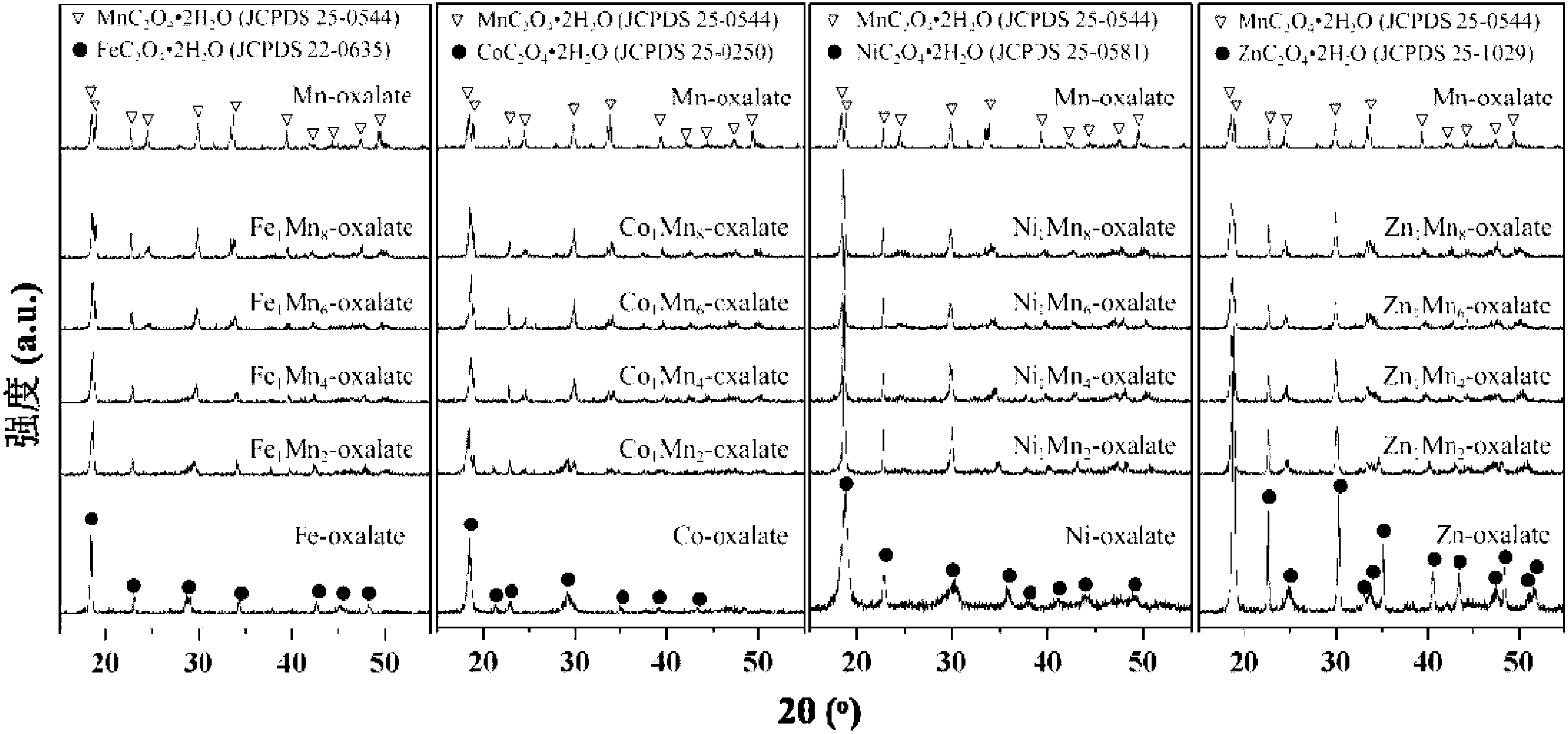

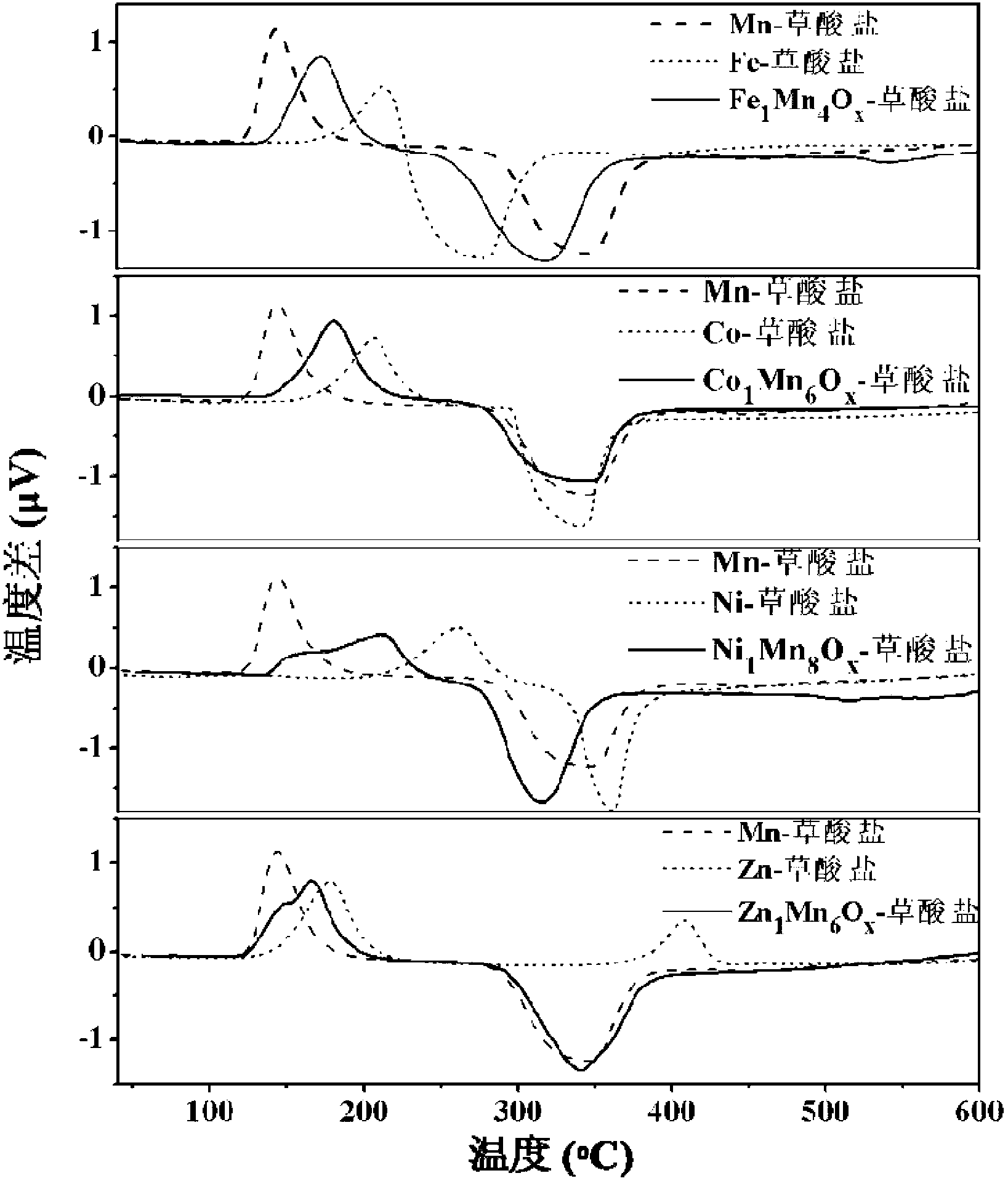

[0032] At room temperature, take a total of 60 mmol of manganese salt (MnCl 2 4H 2 O) and a water-soluble divalent transition metal salt (the molar ratio of manganese salt to divalent transition metal salt is represented by Y, as shown in Table 1) were dissolved together in 80 mL of deionized water. Dissolve 60mmol oxalic acid in 30mL deionized water at 80°C. Under vigorous stirring, the oxalic acid solution was added to the metal ion solution, and the stirring was continued for 1 hour to form a precipitate, which was then suction filtered, washed with water, and dried in an oven at 100°C to obtain a single-phase X-Mn composite metal oxalate. Its XRD pattern is shown in figure 1 Shown, DTA curve see figure 2 shown.

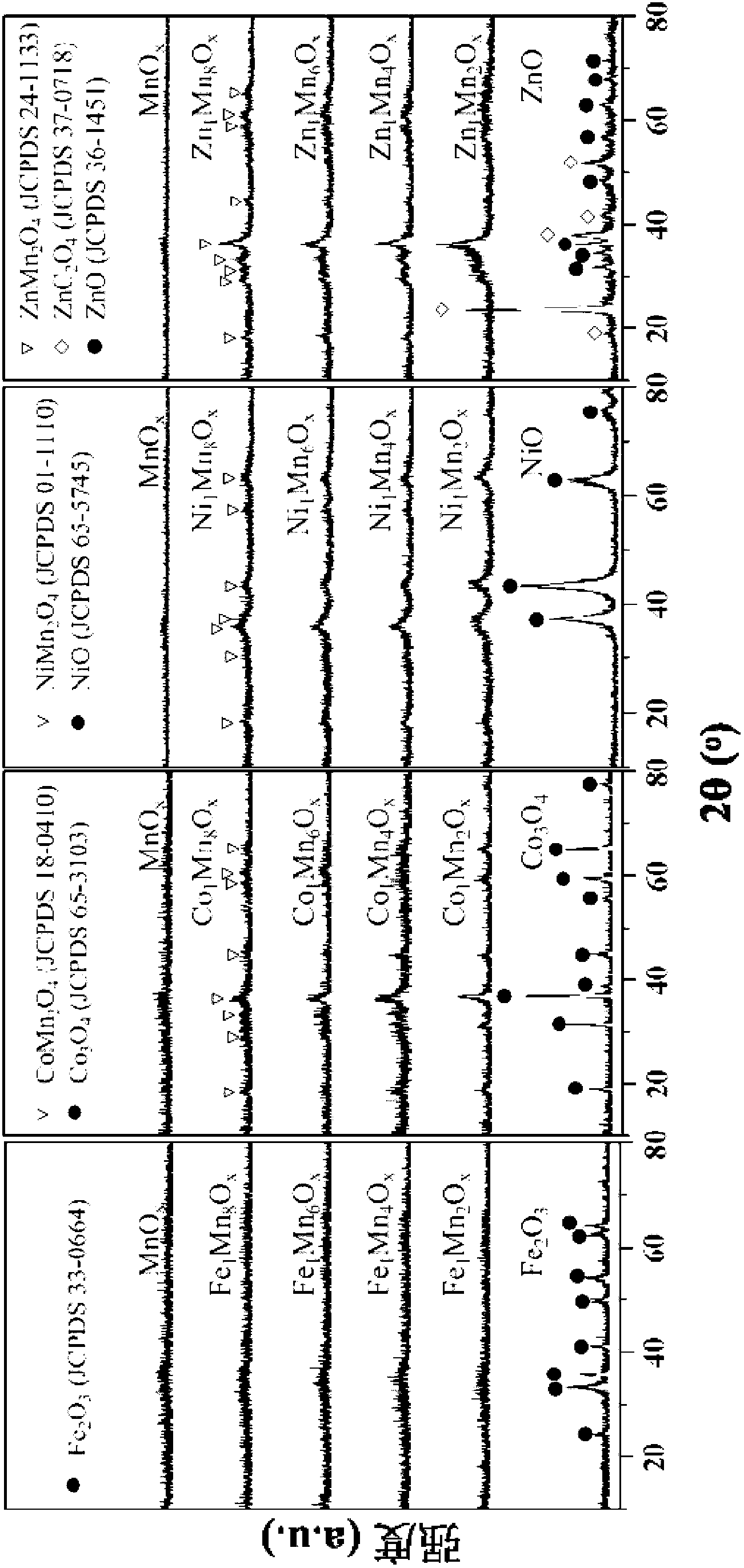

[0033] The single-phase composite metal oxalate was placed in a muffle furnace, and the temperature was raised to 300°C at a rate of 1°C / min under normal pressure, and then kept for calcination for 1 hour to obtain a mesoporous X-Mn composite metal oxide. It...

Embodiment 1~5

[0037] Comparative Examples 1-5 Preparation of Mesoporous Single Metal Oxide

[0038] At room temperature, take 60mmol of metal salt (specific metal salt substances are shown in Table 2) and dissolve in 80mL of deionized water. Dissolve 60mmol oxalic acid in 30mL deionized water at 80°C. Under vigorous stirring, the oxalic acid solution was added to the metal ion solution, and the stirring was continued for 1 hour to form a precipitate, which was then suction filtered, washed with water, and dried in an oven at 100°C to obtain a single-phase monometallic oxalate. Its XRD pattern is shown in figure 1 Shown, DTA curve see figure 2 shown.

[0039] Put the single-phase metal oxalate in a muffle furnace, raise the temperature up to 300°C at a rate of 1°C / min under normal pressure, and then heat-preserve and calcinate for 1 hour to obtain a mesoporous single-metal oxide. Its XRD pattern is shown in image 3 Shown, TEM image see Figure 4 shown.

[0040]Table 2 Preparation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com